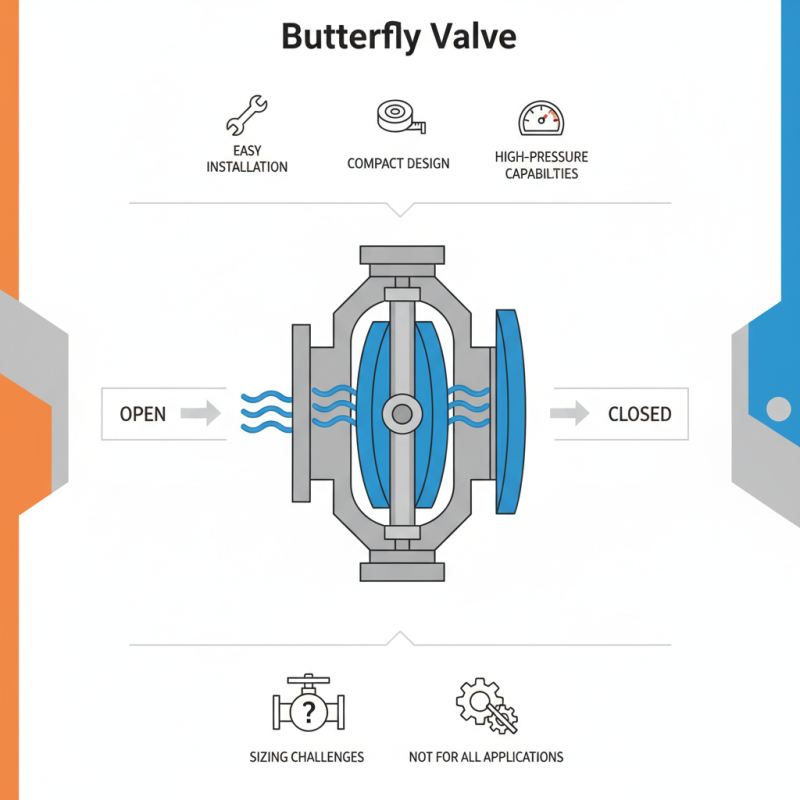

Butterfly valves are vital components in many industries. They control the flow of fluids with ease and efficiency. These valves operate with a simple disc mechanism that rotates. This design allows for quick opening and closing, making them ideal for various applications.

In essence, butterfly valves feature a flat disc that pivots on a shaft. When the valve is fully open, fluid flows freely. When closed, the disc seals tightly against the valve body. Depending on the configuration, these valves can handle high-pressure conditions. However, the design may not be suitable for all situations.

Understanding butterfly valves involves recognizing their advantages and limitations. They are lightweight and take up less space, which benefits installation. Yet, improper sizing can lead to performance issues. It is crucial to consider the specific needs of each system when selecting these valves. This is often overlooked during the planning phase. Balancing efficiency with practicality remains a challenge for many engineers.

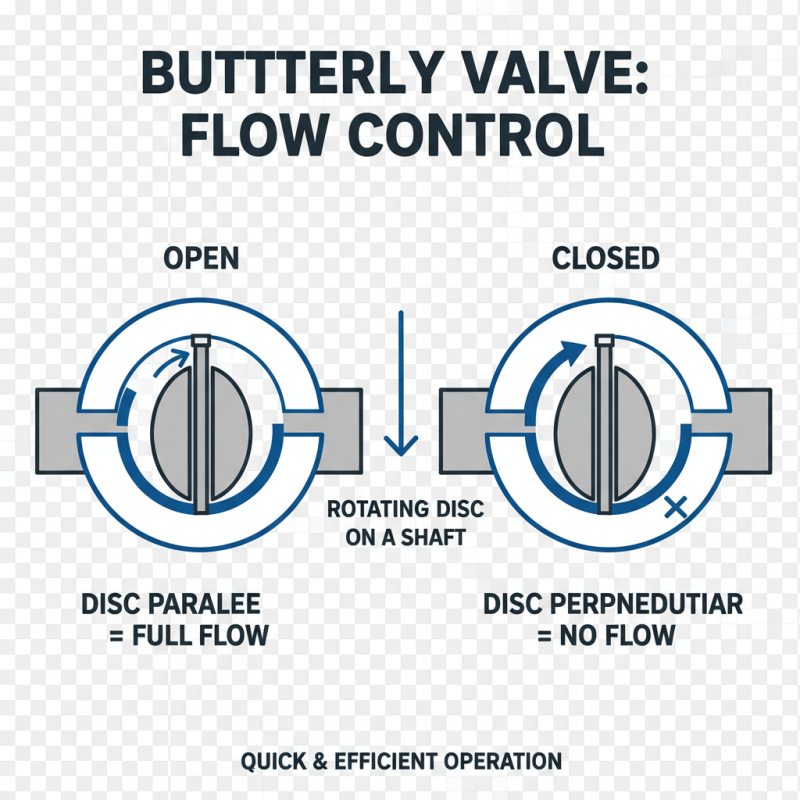

A butterfly valve is a simple yet effective device used to control fluid flow. Its design features a rotating disc that sits in the center of the pipeline. When the valve is closed, the disc completely blocks the flow. When the disc rotates, it allows fluid to pass through. This mechanism makes it ideal for various applications, including water systems and industrial processes.

The construction of a butterfly valve is usually lightweight, making installation easier compared to other types. However, selecting the right material for the disc and body is crucial. Different materials can withstand varying pressure levels and temperatures. A poor choice could lead to leaks or mechanical failure over time. Installing a valve improperly can result in excessive wear or jamming.

Adjustment is also key. Operators must regularly check the valve's condition. An ignored issue could lead to costly repairs. Regular maintenance is often overlooked, yet it is essential for longevity. The balance between efficiency and cost-effectiveness is a challenge. Understanding how a butterfly valve works can help users make better decisions in their operations.

| Feature | Description | Applications | Advantages |

|---|---|---|---|

| What is it? | A butterfly valve is a quarter-turn rotational valve that uses a disk to regulate flow. | Water supply, HVAC systems, waste treatment, and oil refining. | Lightweight, quick operation, low pressure drop, easy maintenance. |

| Working Principle | The valve opens and closes by rotating the disk 90 degrees with an actuator. | Industrial applications, food processing, and fire protection systems. | Simple design, cost-effective, and minimal space requirements. |

| Components | Body, disc, stem, seat, and actuator (manual or automatic). | Waterworks, chemical manufacturing, and power plants. | Durability, versatility, and efficient throttling capability. |

| Types | Lugged, wafer, and vane type butterfly valves. | Pipelines, drainage systems, and fuel stations. | Reduction in energy costs, high flow capacity, and ease of operation. |

A butterfly valve is a simple yet effective device used to control fluid flow. Its primary components play a vital role in how it operates. The valve consists of a circular disc, known as the butterfly, and a stem. The disc rotates around the stem, which allows or blocks fluid passage. This design ensures minimal disruption and maintains pressure efficiently.

The key components of a butterfly valve include the body, disc, stem, and actuator. The body houses the other parts and is typically made from durable materials. The disc is placed perpendicular to the flow direction when closed and is parallel when fully open. The stem connects the disc to the actuator, enabling smooth rotation. Actuators, which can be manual or automated, facilitate quick response in fluid management.

However, installation and maintenance are areas where attention is needed. Improper alignment can lead to leaks. Seals within the valve require regular checks to ensure they function correctly. Over time, wear and tear can affect performance if not addressed. Understanding these components helps in troubleshooting and optimizing valve efficiency. Remember, even a minor oversight can lead to significant issues later on.

A butterfly valve functions as a flow control device. It features a circular disc that rotates on a shaft. This disc regulates fluid flow through a pipeline by either blocking or allowing passage. When the disc is parallel to the flow, it's fully open. Conversely, when it's perpendicular, the valve is closed. This simple mechanism makes it efficient for quick operation.

Operation of a butterfly valve involves a few key parts. The disc creates a tight seal against the body. Research indicates that butterfly valves can handle pressures up to 300 psi in certain applications. They can also operate in temperatures ranging from -20°F to 400°F. These specifications make them versatile across industries. However, they aren't suitable for all scenarios. For example, they may not provide a complete seal in high-pressure environments.

The construction of butterfly valves can vary. Some designs have a resilient seat, enhancing their sealing capabilities. Others utilize metal seats for durability in harsh conditions. It's crucial to select the right type based on the intended application. Though they are easy to install and maintain, neglect in choosing the right valve can lead to leaks or inefficiencies. Therefore, careful assessment is vital in their application.

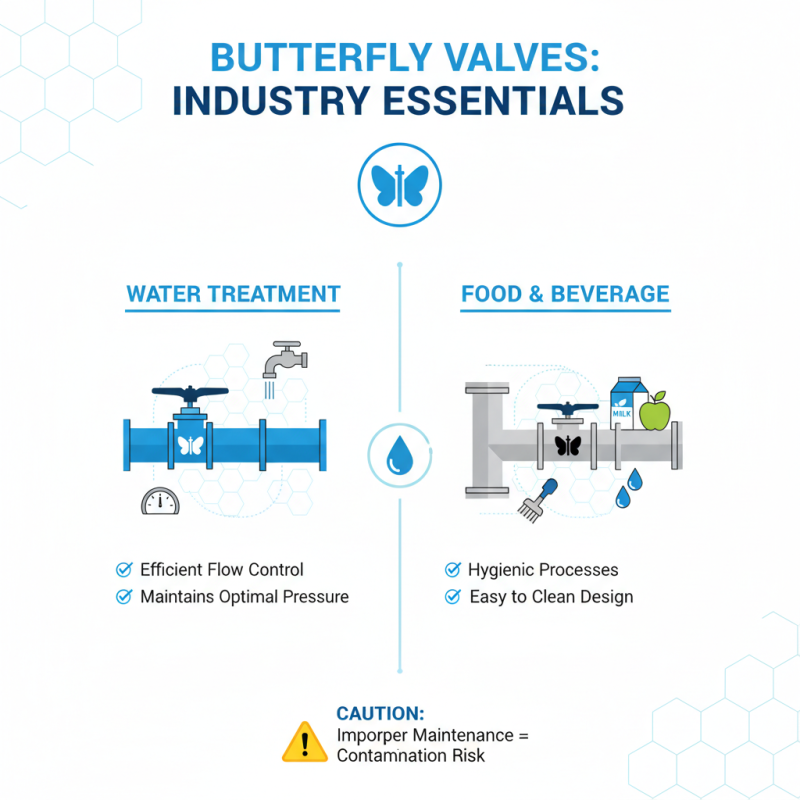

Butterfly valves are widely used across various industries due to their efficiency and versatility. In water treatment facilities, they control the flow of water with minimal resistance. This is crucial for maintaining optimal pressure levels. In the food and beverage sector, they ensure hygienic processes. Their simple design makes cleaning easier, but improper maintenance can lead to contamination.

In the energy sector, butterfly valves play a vital role in pipeline systems. They regulate gas and oil flow, ensuring safety and efficiency. However, the selection of materials is essential. Corrosion can compromise their integrity, resulting in leaks. Careful monitoring and regular inspections are necessary to prevent failures.

Additionally, in HVAC systems, butterfly valves help manage airflow. They assist in temperature regulation. It’s crucial to balance efficiency with comfort. Sometimes, they fail to close completely, leading to energy waste. Operators should address these issues promptly. Understanding these applications helps industries improve their operations, but ongoing evaluation is essential to ensure reliability and performance.

Butterfly valves offer unique advantages in various applications. They are lightweight, simple to operate, and cost-effective. Their design allows for quick opening and closing, making them suitable for large volumes of fluids. Furthermore, they have a small footprint, which saves space in piping systems. This makes them an attractive choice for many engineers.

However, there are disadvantages to consider. Butterfly valves may not provide a tight seal under certain conditions. This can lead to leaks in critical applications. Additionally, their performance can be affected by the medium they control. They are not always ideal for throttling fluids. This can result in issues when precise flow control is necessary.

Another point to reflect on is their durability. While often reliable, butterfly valves can suffer damage in harsh environments. Factors like corrosion can shorten their lifespan. Users must weigh these advantages and disadvantages carefully. Choosing the right valve requires understanding the specific needs of the application.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.