In the ever-evolving landscape of industrial operations, the selection of reliable valves manufacturers is crucial for ensuring efficiency and safety. The global valve market is projected to reach $88.3 billion by 2025, driven by the exponential growth in industries such as oil and gas, water and wastewater management, and power generation. According to a recent report by Markets and Markets, the increasing demand for automation and advanced products has heightened the need for trustworthy valve suppliers who emphasize quality and compliance with international standards.

In this context, the importance of partnering with reputable valves manufacturers cannot be overstated. These manufacturers not only provide high-performance products but also contribute to minimizing operational risks and enhancing system reliability. As industries worldwide continue to focus on sustainability and efficiency, selecting a manufacturer with a proven track record and comprehensive support services becomes paramount.

The right valves can significantly impact a plant's productivity and safety protocols, making informed choices essential for long-term success. Thus, understanding the benefits of collaborating with established valves manufacturers is vital for any industrial player aiming to thrive in a competitive market.

When it comes to industrial applications, partnering with established valve manufacturers is crucial for ensuring reliability, safety, and performance. Research from the Global Valve Market Report indicates that the demand for high-quality valves is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2021 to 2026, underscoring the importance of selecting trusted manufacturers who meet rigorous standards.

Established valve manufacturers invest significantly in research and development, ensuring their products are not only compliant with industry regulations but also innovative, enhancing efficiency and reducing downtime in industrial processes.

Moreover, working with seasoned valve manufacturers provides access to their extensive expertise and industry knowledge. Data from a survey conducted by the Valve Manufacturers Association reveals that 87% of industrial operators report improved operational efficiency when using products from reputable manufacturers. This is largely due to the rigorous testing and quality assurance processes that established companies implement, resulting in valves that exhibit superior reliability and longevity. By choosing trusted valve manufacturers, businesses can mitigate risks, enhance productivity, and ultimately achieve greater profitability in their operations.

When selecting trusted valve suppliers for industrial needs, several key criteria must be considered to ensure efficiency and reliability in the supply chain. First, assessing the manufacturer’s reputation in the industry is crucial. Look for suppliers with a proven track record of delivering high-quality products and excellent customer service. Reviews, testimonials, and case studies can provide insights into their reliability and performance.

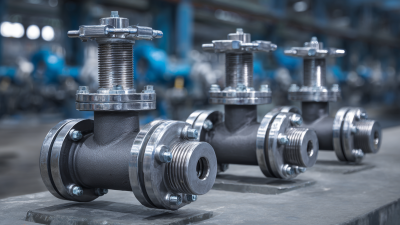

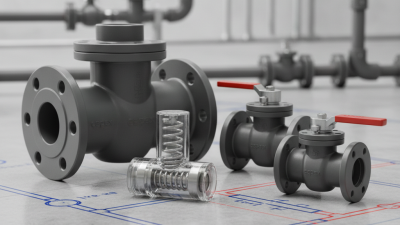

Additionally, evaluating the range of products offered by valve manufacturers is essential. A trusted supplier should provide a diverse portfolio of valves that meet various industrial standards and specifications. This diversity not only ensures that you can find the right fit for your specific needs but also indicates the manufacturer's expertise and commitment to quality. Finally, consider the supplier's compliance with regulatory standards and certifications, which are crucial for maintaining safety and operational integrity in industrial applications.

Choosing trusted valves manufacturers is crucial for ensuring operational efficiency and maintaining safety standards in industrial applications. Quality valves are integral components in various systems, and their performance directly impacts productivity. According to a report by MarketsandMarkets, the global valve market is expected to reach USD 82.5 billion by 2027, highlighting the growing importance of reliable valve solutions across industries. Poor quality valves can lead to leaks, equipment failures, and costly downtimes, underscoring the need for stringent supplier selection.

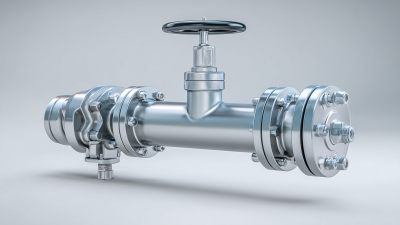

The impact of quality valves on safety cannot be overstated. A study from the American Society of Mechanical Engineers reveals that up to 40% of industrial accidents are linked to valve failures. Employing high-quality valves manufactured by reputable companies significantly reduces the risk of such failures. For instance, valves that meet or exceed industry standards, such as ISO 9001 and API certifications, are proven to enhance system reliability and longevity. Investing in trusted valve manufacturers not only safeguards operational integrity but also optimizes maintenance schedules and compliance with regulatory requirements.

When selecting a valve manufacturer for industrial needs, asking the right questions can significantly impact the effectiveness and reliability of your operations. Start by inquiring about the manufacturer's experience in your specific industry. Understanding their track record can provide insights into their capabilities and expertise. You should also ask about the certification and compliance of their products with industry standards, as this ensures that the valves meet quality and safety requirements.

Tips: Always verify the manufacturing process and quality control measures employed by the manufacturer. It’s essential to ensure that they use advanced technology and have stringent testing protocols to guarantee the reliability of their products.

Another crucial question to consider is their customer service and support structure. A good manufacturer should not only provide high-quality products but also be responsive to your needs post-purchase. This includes offering maintenance support and being ready to address any issues that may arise.

Tips: Evaluate the responsiveness and communication style of the manufacturer during your initial interactions. A proactive approach to customer care often indicates a commitment to quality and long-term partnerships.

When it comes to industrial needs, choosing trusted valve manufacturers can significantly enhance operational efficiency. One compelling example comes from a major chemical production facility that faced frequent downtime due to valve failures. By switching to a reputable manufacturer known for rigorous quality control and innovative designs, the facility saw a remarkable reduction in unplanned outages. These high-quality valves not only improved the reliability of fluid handling but also ensured safety protocols were adhered to more effectively, showcasing the direct impact of trusted manufacturers on productivity.

Another success story involves a water treatment plant that struggled with fluctuating pressure levels, which affected its overall output. After collaborating with a well-established valve manufacturer, the plant implemented custom-engineered valves designed to handle the specific challenges of their system. This tailored approach resulted in enhanced flow management and stabilized pressure levels, culminating in a 20% increase in operational efficiency. Such instances illustrate that partnering with trusted valve manufacturers is not just about acquiring products; it’s about forging relationships that lead to sustainable improvements in industrial productivity.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.