In today's industrial landscape, selecting the right valves manufacturers is crucial for operational success. Valves play a vital role in controlling fluid flow, ensuring safety, and improving efficiency. Numerous manufacturers compete to provide high-quality valves tailored to various applications. Identifying the best ones requires careful consideration.

Many manufacturers showcase impressive innovations and extensive product lines. However, not all meet the rigorous demands of every industry. Some may lack durability or compatibility with specific environments. Evaluating each manufacturer’s reputation and track record is essential. Reviews and case studies can offer insights into their performance and reliability.

Moreover, choosing a manufacturer involves looking beyond price. The cheapest option may not always yield the best results. Finding a balance between affordability and quality requires thorough research. This process can be challenging but is crucial for making informed decisions in selecting valves manufacturers.

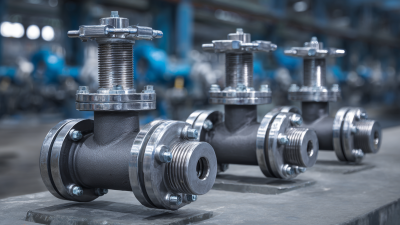

Industrial valves are crucial in various applications, from oil and gas to water treatment. They regulate flow and pressure, ensuring efficient system operations. Reports suggest that the global valve market is projected to reach $98.3 billion by 2025. This growth reflects increased demand across industries.

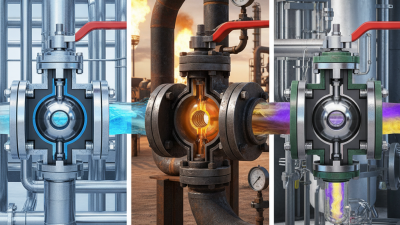

Different valve types serve unique functions. Gate valves are common for on-off control. Globe valves manage flow regulation effectively. Ball valves offer quick shut-off capabilities. According to market studies, the demand for ball valves is predicted to grow at a compound annual growth rate (CAGR) of 6.5%. However, choosing the right type can be a challenge.

Considerations include pressure ratings, temperature ranges, and materials. Some may overlook maintenance needs, leading to failures. Implementing a maintenance schedule is vital for reliability. Additionally, attention to installation practices can prevent leaks. The importance of selecting appropriate valves cannot be overstated, as the wrong choice may lead to costly downtime.

Selecting the right valve manufacturer is crucial for industrial efficiency. A report by the International Valve Manufacturers Association states that about 70% of industrial failures are linked to valve issues. Therefore, evaluating manufacturers based on specific criteria is vital.

Quality control is paramount. Look for manufacturers with stringent testing protocols. They should adhere to ISO standards and utilize advanced technologies in production. Studies indicate that companies with robust quality management systems reduce failures by 30%.

Customer support and service are equally important. Timeliness in responding to inquiries can make or break operational success. Effective communication can speed up resolution times and enhance project outcomes. A survey revealed that 65% of buyers prioritize manufacturers with strong after-sales support.

Lastly, consider customization capabilities. Flexible manufacturers can adapt to unique operational needs. This adaptability often translates into longer-term satisfaction and efficiency gains.

In the global market, selecting the right valve manufacturer is crucial for industrial success. The industry is filled with players, each offering unique products and services. When evaluating these companies, consider key factors such as product quality, technology, and reliability. Some manufacturers excel in innovative designs, while others boast a long-standing reputation for durability.

An important detail to consider is the specialized application of each valve type. For instance, certain manufacturers may focus on high-pressure systems, while others may cater to more niche markets. This specialization can sometimes be a double-edged sword. While it allows for tailored solutions, it may also limit versatility. This requires careful thought when you choose your supplier.

Additionally, it’s beneficial to monitor customer feedback and industry trends. Some manufacturers may struggle to adapt to changing demands. Their inability to innovate could hinder their growth. Thus, assessing how a manufacturer responds to market shifts is important. A company’s flexibility can be as vital as its product line. Knowing these details helps you make an informed decision for your industrial needs.

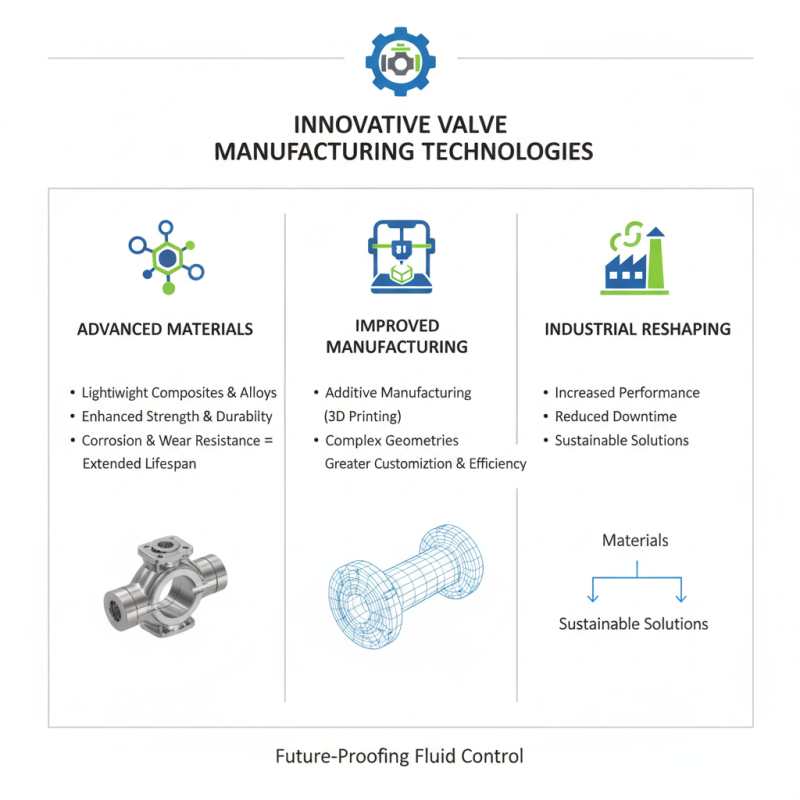

Innovative technologies in valve manufacturing are reshaping the industrial landscape. Advanced materials play a crucial role in this transformation. Lightweight composites and alloys enhance strength and durability. These materials resist corrosion and wear, extending the lifespan of valves. Improved manufacturing processes, such as additive manufacturing, create complex geometries. This allows for greater customization and efficiency in production.

Automation is another key component. Robotic systems streamline the assembly process. This reduces human error and improves precision. Machine learning algorithms analyze performance data. They predict maintenance needs and optimize operations. Such advancements drive productivity in various sectors.

However, innovation is not without challenges. High initial costs can deter smaller businesses. Not all manufacturers have access to cutting-edge technologies. Additionally, adapting to new materials requires skilled labor. There is a gap between traditional practices and modern techniques. This discrepancy raises questions about training and workforce development. The path forward involves bridging these gaps, fostering collaboration, and embracing change.

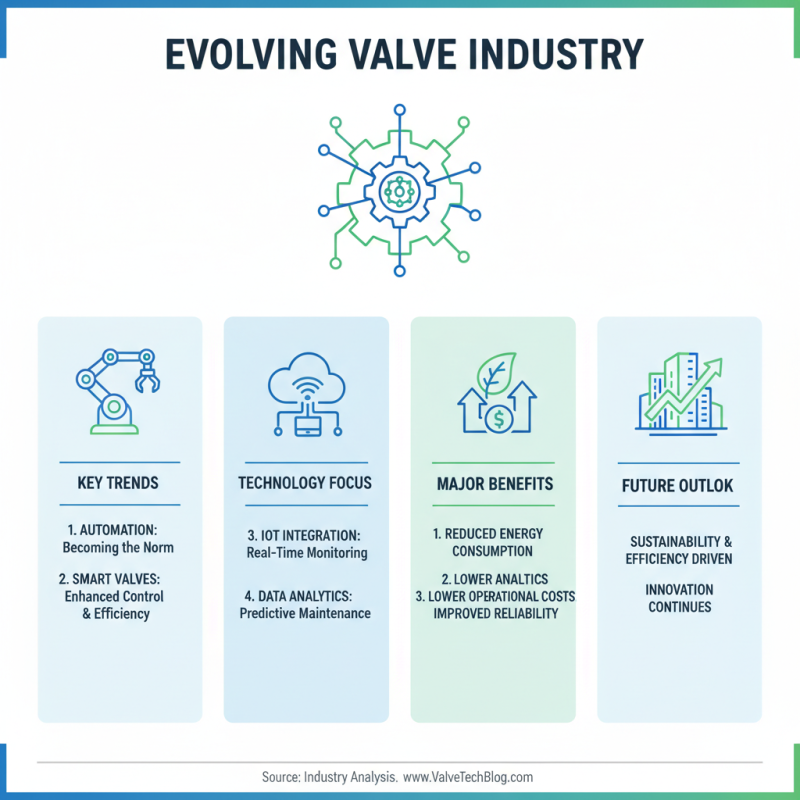

The valve industry is evolving rapidly. Emerging technologies play a crucial role in this transformation. Automation is becoming the norm. Smart valves are gaining traction, offering enhanced control and efficiency. This shift promises to reduce energy consumption and operational costs. Companies are now investing in Internet of Things (IoT) integration. Real-time monitoring is benefiting maintenance strategies.

Sustainability is another key trend. Manufacturers are developing eco-friendly materials. This move addresses environmental concerns while ensuring product longevity. Yet, some manufacturers struggle with sourcing sustainable components. This inconsistency can impact their market positioning. Furthermore, the growing demand for custom solutions poses challenges. Many companies grapple with production scalability while maintaining quality. Innovations are necessary, but they require time and resources to implement effectively.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.