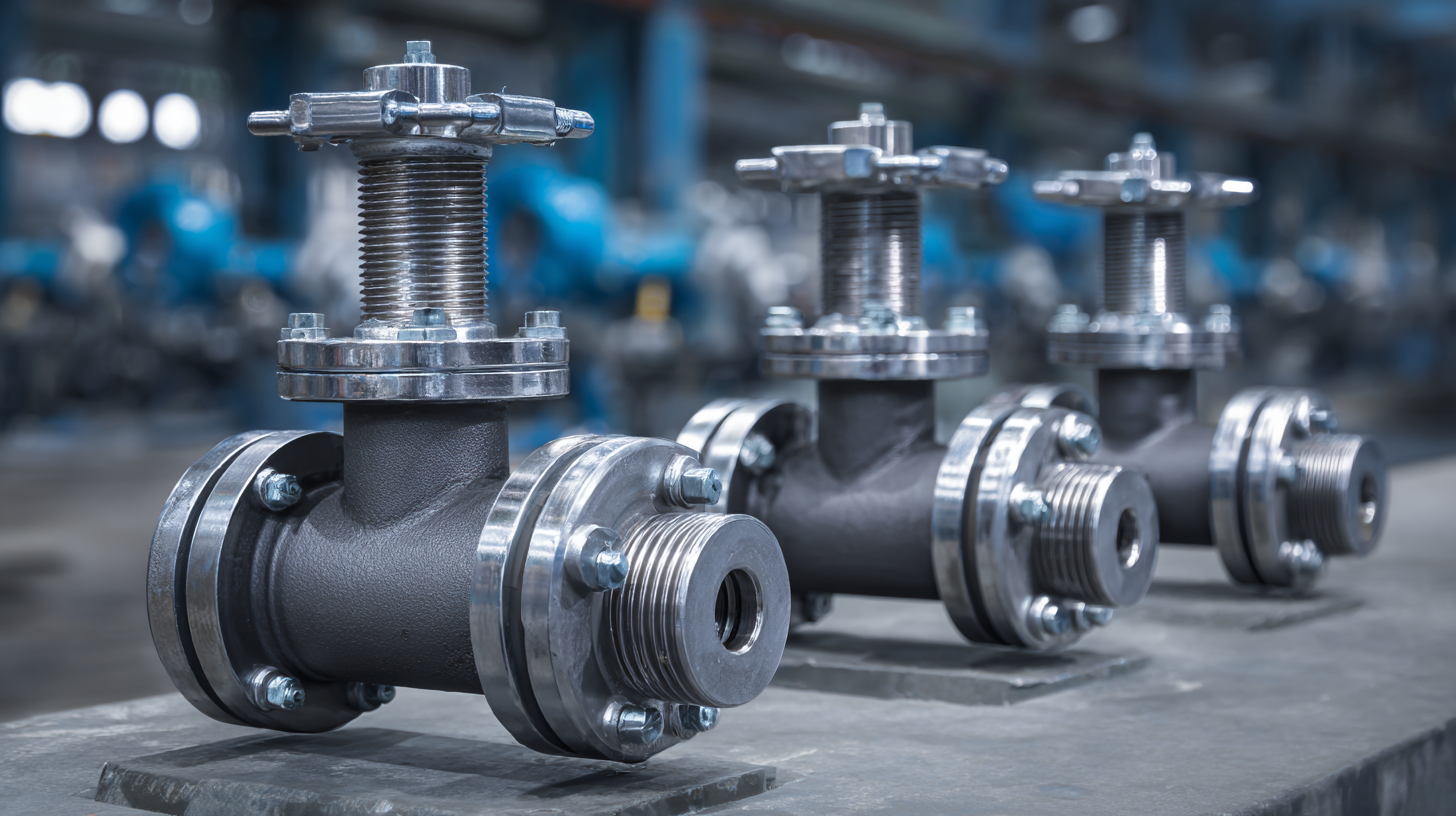

In the dynamic landscape of fluid control systems, understanding the intricacies of valve fittings is paramount for achieving optimal efficiency. As industries strive for precision in fluid handling, the role of high-quality valve fittings becomes increasingly crucial. According to a report by the Global Fluid Control Market Research Institute, the demand for advanced valve fittings is projected to grow by over 10% annually through 2026, reflecting the critical need for innovation in this sector.

Experts in the field highlight the impact of effective valve fittings on operational performance. Dr. Emily Carter, a prominent authority in fluid mechanics, once stated, “The efficiency of a fluid system largely hinges on the integrity and design of its valve fittings. They are the unsung heroes in maintaining system reliability and performance.” This sentiment underscores the underlying importance of selecting the right valve fittings for various applications, ensuring not only compliance with safety standards but also optimizing flow management and reducing potential downtime.

As we delve into the Top 10 Valve Fittings You Need to Know for Optimal Fluid Control Efficiency, this outline will explore essential types, their applications, and best practices that can significantly enhance fluid control strategies in diverse industrial settings. Understanding these key fittings will empower engineers and technicians to make informed decisions that bolster efficiency and performance across fluid systems.

Choosing the right valve fittings is crucial for achieving optimal fluid control efficiency in various applications, particularly in industries like pharmaceuticals and biotechnology. The use of diaphragm valves in pharmaceutical processes is projected to grow significantly, with a market value expected to rise from $123.3 million in 2024 to $284.6 million by 2032, reflecting a robust compound annual growth rate (CAGR) of 11.02%. This remarkable growth underscores the importance of selecting high-quality valve fittings that can handle stringent regulatory requirements and precise fluid control for drug manufacturing processes.

Additionally, the advancements in technology, such as the development of piezoelectric valves, are expected to further drive market demand. The piezoelectric valve market was valued at $50 million in 2022 and is anticipated to reach $90 million by 2030, with a CAGR of 7.5% from 2024 to 2030. These valves not only enhance efficiency but also improve reliability in fluid control applications, making them essential components in modern medical devices and automated systems. As industries increasingly prioritize efficiency and accuracy, understanding and selecting the right valve fittings becomes imperative for maintaining operational excellence.

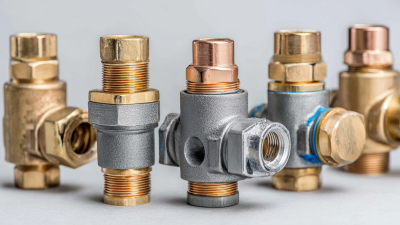

When selecting high-performance valve fittings for optimal fluid control efficiency, there are several key features to consider. One critical aspect is the material composition of the fittings. Options such as stainless steel and brass are recommended for their corrosion resistance and durability, as outlined in the 2022 Fluid Control Report which indicates that 70% of fluid system failures are linked to material degradation. Moreover, a fitting's pressure rating is essential; fittings designed to handle higher pressures can prevent leaks and boost overall system safety.

Another feature to prioritize is the fitting's design for ease of installation and maintenance. Fittings that facilitate quick connections or disconnections can significantly reduce downtime, a valuable asset in any industrial application. According to a recent study by the Fluid Engineering Association, systems utilizing user-friendly fittings can achieve up to a 30% reduction in maintenance time. Additionally, compatibility with existing systems—ensuring standard size connections and flow paths—can further enhance efficiency and performance. By focusing on these critical attributes, businesses can optimize their fluid control systems and improve operational effectiveness.

| Valve Type | Key Features | Material | Pressure Rating | Temperature Range |

|---|---|---|---|---|

| Ball Valve | Quick opening/closing, minimal flow resistance | Brass, Stainless Steel | 150 psi | -20°C to 120°C |

| Gate Valve | Full flow, good for on/off service | Cast Iron, PVC | 200 psi | -10°C to 80°C |

| Globe Valve | Excellent for throttling, good flow regulation | Stainless Steel, Bronze | 150 psi | -20°C to 150°C |

| Check Valve | Prevents backflow, automatic operation | PVC, Stainless Steel | 100 psi | 0°C to 80°C |

| Butterfly Valve | Compact design, quick shutoff | Aluminum, PVC | 150 psi | -10°C to 90°C |

| Pressure Relief Valve | Safety feature to prevent overpressure | Brass, Stainless Steel | 200 psi | -20°C to 120°C |

| Solenoid Valve | Automated operation, remote control | Brass, Plastic | 125 psi | -10°C to 80°C |

| Pressure Regulating Valve | Maintains constant pressure, flow control | Stainless Steel, Nylon | 150 psi | -20°C to 100°C |

| Diverter Valve | Directs flow, multi-way control | Brass, PVC | 150 psi | 0°C to 80°C |

| Ball Check Valve | Prevents backflow, high flow rate | Stainless Steel, Plastic | 100 psi | -10°C to 80°C |

In 2025, the efficiency of fluid control systems will increasingly hinge on the selection of the right valve fittings. Among the top fitting types, compression fittings are gaining traction for their ability to provide a tight seal without the need for threads, which can wear out over time. This feature reduces leakage risks and enhances system reliability, making it an excellent choice for high-pressure applications.

Another key type is push-fit fittings, known for their ease of installation and maintenance. In environments where quick adjustments are necessary, push-fit fittings can save significant time and reduce labor costs. Furthermore, they offer flexibility in system design, allowing for easy expansions or modifications.

Lastly, ball valve fittings will remain essential due to their simple operation and durability. These fittings can effectively control flow with just a quarter turn, making them ideal for processes where quick shut-off is crucial. The combination of these advanced fitting types will undoubtedly enhance fluid control efficiency, making them indispensable components in future systems.

Innovative technologies are revolutionizing the valve fitting sector, with digital advancements and automation emerging as key players in enhancing fluid control efficiency. The rise of smart valves and automated systems is allowing for real-time monitoring and adjustment, significantly improving both responses to fluid dynamics and overall process efficiency. As companies introduce advanced materials and design techniques, these innovations are not only optimizing performance but also increasing customization capabilities for various industrial applications.

Innovative technologies are revolutionizing the valve fitting sector, with digital advancements and automation emerging as key players in enhancing fluid control efficiency. The rise of smart valves and automated systems is allowing for real-time monitoring and adjustment, significantly improving both responses to fluid dynamics and overall process efficiency. As companies introduce advanced materials and design techniques, these innovations are not only optimizing performance but also increasing customization capabilities for various industrial applications.

Furthermore, the integration of digital tools within the valve industry is paving the way for new trends in data analytics and predictive maintenance. This shift allows operators to anticipate failures and reduce downtime, resulting in enhanced reliability and longevity of valve fittings. With the continued evolution of valve technologies, from advanced pneumatic actuators to digitally controlled systems, the future of fluid control is poised to become more efficient and tailored to specific operational needs. These advancements are reshaping how industries approach fluid management, making it a critical area of focus for businesses aiming for optimal performance.

When it comes to the maintenance and installation of valve fittings, adhering to best practices is critical for achieving optimal fluid control efficiency. Firstly, it’s essential to select the right fitting materials that match the fluid type and operating conditions. Corrosion-resistant materials, for instance, are recommended for harsh chemical environments to prevent premature failures. During installation, ensure that all fittings are correctly aligned and securely tightened to avoid leaks. Utilizing the appropriate torque specifications prevents overtightening, which can compromise the fitting integrity.

Additionally, regular maintenance is vital for prolonging the lifespan of valve fittings. A systematic inspection routine should include checking for leaks, wear, and any signs of corrosion or degradation. Lubricating threaded connections can facilitate easier disassembly and reassembly during maintenance. It’s also beneficial to keep detailed records of inspections and replacement schedules, which can enhance operational reliability. Adopting these best practices not only enhances fluid control efficiency but also minimizes unforeseen downtime and associated costs.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.