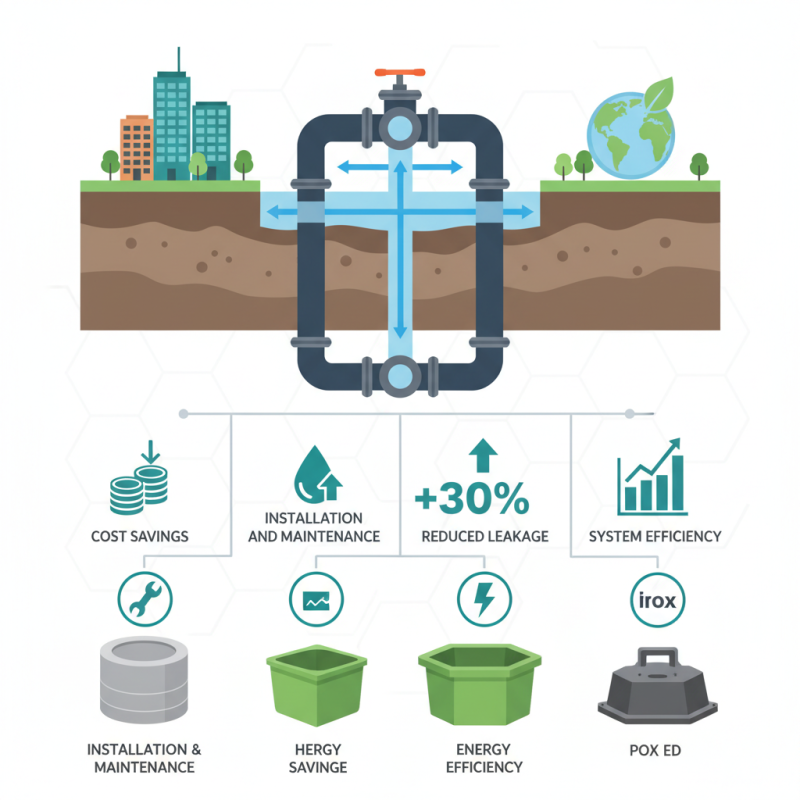

Efficient water management is crucial for sustainable urban development. According to the American Society of Civil Engineers, aging water infrastructure costs cities billions annually. To address these challenges, valve boxes play a vital role in controlling water flow and maintaining system integrity. They are essential for both residential and commercial applications.

Recent studies show that proper installation and maintenance of valve boxes can reduce leakage by up to 30%. However, many municipalities overlook this component, leading to costly repairs and water waste. Selecting the right valve boxes can significantly enhance system efficiency. Energy consumption during water distribution can be lowered by effective valve management, which is often neglected in current practices.

The market for valve boxes is evolving, with innovative designs and materials enhancing performance. Still, it's vital to choose options that meet specific operational needs. As we explore the top valve boxes on the market, we must reflect on the balance between cost and efficiency. It's not just about purchasing a product; it's about investing in sustainable water solutions.

Valve boxes play a crucial role in water management. They protect valves and provide access for maintenance. Proper installation can greatly enhance system efficiency.

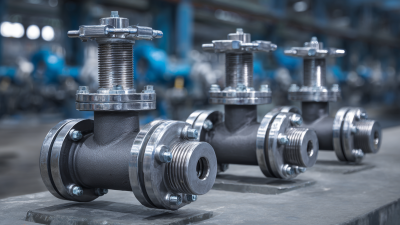

These boxes are typically made from durable materials. They withstand environmental pressures and harsh conditions. An effective valve box should have a solid cover. This prevents soil and debris from obstructing access. It’s surprising how often dirt clogs these systems. Regular checks can help prevent costly repairs.

Tips: Always ensure that the valve box is easily accessible. This might seem simple but can save time during emergencies. Consider labeling the boxes for quick identification. This avoids confusion in urgent situations. Regular maintenance checks should include the valve box area. Look for any signs of wear or damage.

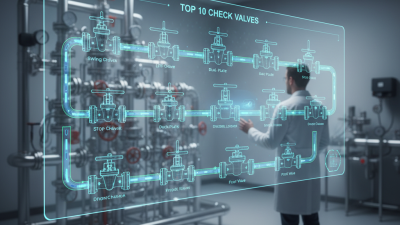

When it comes to efficient water management, valve boxes play a crucial role. They provide access to valves and facilitate repairs without disrupting the surrounding area. There are several types commonly used in water systems.

One popular type is the concrete valve box. These boxes are durable and can withstand significant pressure. However, they can be heavy and challenging to install. If the installation is not done properly, it may lead to misalignment.

Another option is the plastic valve box. Lightweight and easier to handle, these boxes resist corrosion well. They are often used in residential areas. Still, they may not hold up in extreme weather conditions.

Tips: Always check with local regulations on materials. Choose a valve box that fits your project's specific needs. Consider the environment the box will be placed in. Proper installation is key to ensuring long-lasting function.

When selecting the right valve box for your water management system, consider materials carefully. Durable materials ensure longevity and resistance to environmental factors. Options include plastic and concrete, each with its unique benefits. Plastic is lightweight and corrosion-resistant. On the other hand, concrete offers robust support but can be heavier.

Tip: Assess the climate in your area. Extreme temperatures can affect material performance. A box that withstands various conditions will save time and money.

Next, pay close attention to size. A well-sized valve box allows easy access for maintenance. Oversized boxes can lead to instability, while undersized boxes may complicate repairs. The fit should cater to both the valve and the surrounding space.

Tip: Measure twice, install once. Accurate measurements can prevent installation hassles. Taking time to measure ensures a better workflow in the long term.

Lastly, look for security features. A secure valve box protects your infrastructure from tampering and accidental damage. Options include lockable lids or heavy-duty designs. However, these features can sometimes complicate access for maintenance.

Tip: Balance security and accessibility. A too-secure box may frustrate personnel needing quick access in emergencies. Be prepared to rethink your choices based on usability.

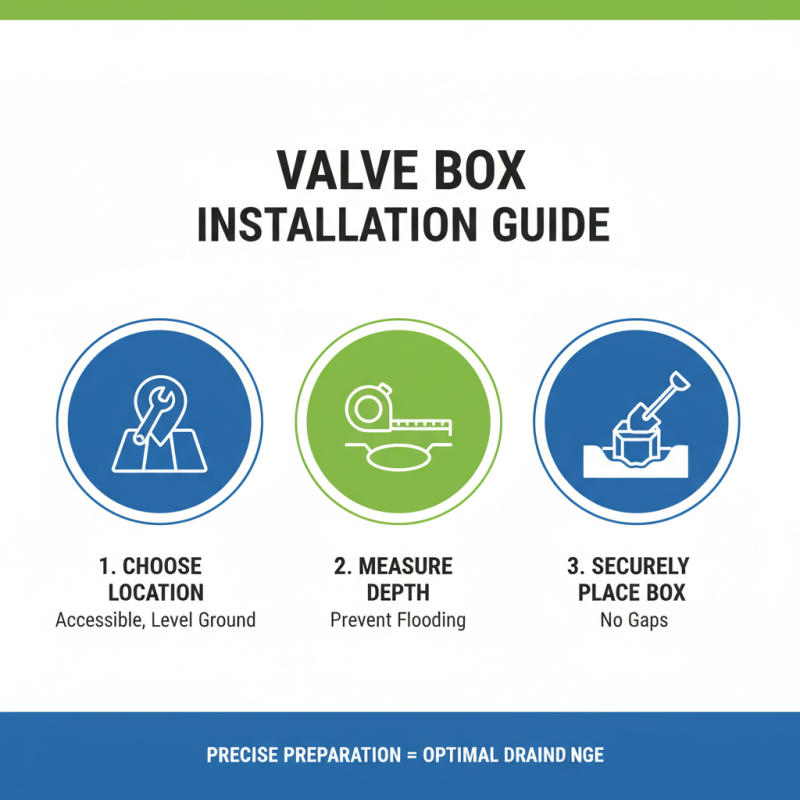

When it comes to installing valve boxes, proper preparation is essential. Start by choosing a location that is easily accessible. The ground should be level and free of debris to ensure a tight fit. Take the time to measure the required depth accurately. Miscalculations can lead to issues like flooding or insufficient drainage. Use a shovel or a spade for precise digging. Make sure the box sits securely in the hole without any gaps.

Maintenance is just as critical. Regular inspections can prevent costly repairs. Check for soil erosion around the valve box. If you see signs of wear, address them quickly. Cleaning the box is also necessary. Remove leaves or mud that could clog the system. It's best to schedule these tasks during dry seasons to minimize disturbances. A little effort can significantly impact long-term performance. Take note of any changes in water flow. They often signal underlying problems that need attention.

Emerging technologies in valve box design are transforming water management. Innovative materials, such as advanced composites, enhance durability and reduce maintenance needs. These materials are lightweight, making installation easier and more efficient. Additionally, some designs now integrate smart sensors that monitor water flow and pressure in real-time. This integration offers valuable data for better decision-making.

New valve box designs focus on sustainability. They feature rainwater harvesting systems that collect stormwater for reuse. This capability minimizes runoff and conserves precious water resources. However, not all designs meet the ideal efficiency standards. Some may require frequent upkeep, leading to higher operational costs. It's crucial to analyze long-term benefits versus immediate challenges.

Another aspect is accessibility. Adjustable designs are needed to cater to various environments and terrains. Some installations fail because they overlook local conditions. Proper insulation, for example, is often neglected but essential in colder climates. Addressing these details can significantly improve overall performance and reliability in the field.

| Model | Material | Size (inches) | Weight (lbs) | Key Features |

|---|---|---|---|---|

| Model A | Polyethylene | 24 x 24 | 15 | UV Resistant, Lightweight |

| Model B | Fiberglass | 30 x 30 | 20 | Corrosion Resistant, High Strength |

| Model C | Concrete | 36 x 36 | 40 | Heavy Duty, Weather Resistant |

| Model D | Steel | 48 x 48 | 60 | Secure Locking Mechanism, Durable |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.