Pressure fittings play a crucial role in various piping systems. They ensure secure connections between pipes and components. Understanding the different types of pressure fittings can help you make informed choices for your projects.

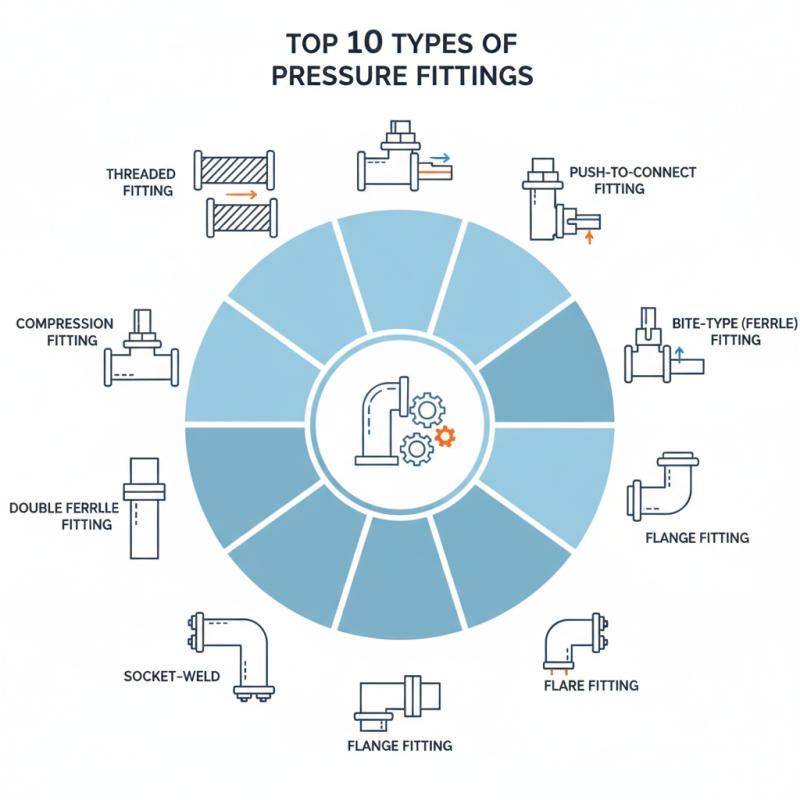

There are many types of pressure fittings available today. Each type has its specific applications and strengths. From threaded fittings to compression fittings, knowing these options is essential for any engineer or technician. Using the wrong type can lead to leaks or failures, which can be costly.

Pressure fittings are not always straightforward. Sometimes, you may overlook a detail and face issues later on. It is vital to reflect on your choices and continuously learn about new fitting options. By doing so, you can avoid mistakes and create reliable systems.

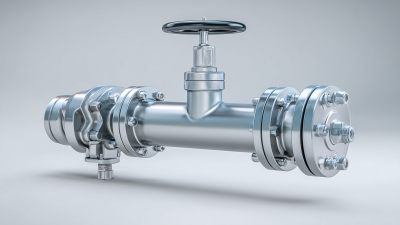

Pressure fittings are essential components in many plumbing and industrial systems. They connect pipes, valves, and machinery. Understanding their types and applications is crucial for anyone working in these fields. These fittings are designed to withstand high pressure, preventing leaks and ensuring stability. Common materials include metals and plastics, which affect their durability and performance.

One of the main types is the socket weld fitting. It offers strong connections and is used in high-pressure applications. Another notable type is the threaded fitting, which allows for easier assembly. However, improper installation can lead to failures. It is important to follow guidelines when using pressure fittings.

Choosing the right fitting requires careful consideration. Not all fittings suit every application. Some may require special treatment or additional components. Always check compatibility. This can help avoid costly errors later on. Regular inspection of fittings is also necessary. Wear and tear can compromise their effectiveness over time.

| Type of Pressure Fitting | Material | Typical Application | Pressure Rating (PSI) |

|---|---|---|---|

| Elbow | Stainless Steel | Pipelines | 1500 PSI |

| Tee | Carbon Steel | Water Supply | 2000 PSI |

| Reducer | Copper | HVAC Systems | 100 PSI |

| Coupling | PVC | Irrigation | 150 PSI |

| Cap | Brass | Oil and Gas | 3000 PSI |

| Flange | Aluminum | Industrial Piping | 5000 PSI |

| Union | Stainless Steel | Chemical Processing | 2500 PSI |

| Bushing | PVC | Construction | 100 PSI |

| Male/Female Adapter | Brass | Water Systems | 1500 PSI |

| Check Valve | Cast Iron | HVAC | 150 PSI |

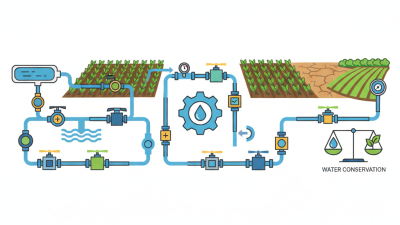

Pressure fittings are crucial in many industries. Their applications range from plumbing to oil and gas. A few common types include compression fittings and flare fittings. Compression fittings are used widely in water supply systems. They create a tight seal, preventing leaks.

Flare fittings provide a secure connection for gas lines. They rely on a conical shape to create a reliable seal. However, they can be tricky to install if not aligned properly. O-ring fittings are another type used to seal high-pressure environments. The rubber O-ring helps to absorb shocks, but it can wear out over time.

Each type of fitting serves a unique purpose. It’s essential to choose the right fitting for the job. Missteps can lead to significant problems. Inspecting your fittings regularly is a crucial step often overlooked. Even a small flaw can cause leaks or failures.

Pressure fittings are crucial in various industries, including oil and gas, water distribution, and HVAC systems. Understanding their key features can optimize system performance. For example, stainless steel pressure fittings offer excellent corrosion resistance. They are ideal for harsh environments, ensuring longevity and safety in operations.

Copper fittings are another common choice, known for thermal conductivity. They are often used in plumbing systems. According to industry reports, copper fittings can handle high-pressure applications effectively, making them reliable. However, weight can be an issue in some installations. PVC pressure fittings are lightweight and resistant to chemicals, suitable for diverse applications.

Notably, many engineers debate the efficacy of each type. Some argue that while brass fittings are versatile, they may not be suitable for all fluids. Others find that choosing the wrong fitting material can lead to system failures. Awareness of each fitting’s characteristics helps in selecting the right one. Regular maintenance and inspections are necessary to ensure performance meets expectations.

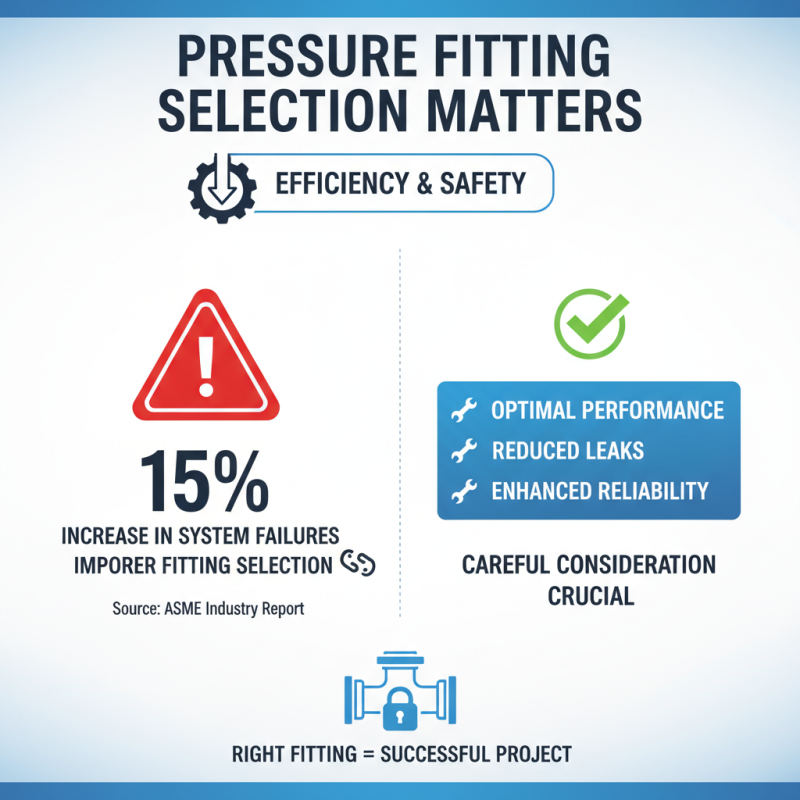

Selecting the right pressure fitting can significantly impact the efficiency and safety of your project. A recent industry report by the American Society of Mechanical Engineers indicates that improper fitting selection can lead to a 15% increase in system failures. This statistic underscores the necessity for careful consideration.

Pressure fittings come in various types, including threaded, welded, and flanged options. Each type has unique installation requirements and pressure ratings. For instance, threaded fittings are ideal for low-pressure applications, while welded fittings are better suited for high-pressure environments. The material is also crucial; stainless steel is often preferred in corrosive settings, while plastic may be sufficient for less demanding tasks. Neglecting these specifics can lead to costly project overruns and equipment damage.

Moreover, fitting sizes and tolerances are critical. According to recent studies, a 2% miscalculation in fitting size can result in leaks or reduced flow efficiency. When selecting fittings, it’s essential to understand the system's operational conditions deeply. Don't rush the decision-making process. Taking the time to analyze your project needs can save you time and money in the long run. Design choices often reflect a blend of engineering knowledge and practical experience. Therefore, consider both the technical specifications and the broader implications of your selection.

Installing and maintaining pressure fittings is crucial for ensuring safety and efficiency. When selecting fittings, always consider the right material. Different environments demand specific materials. For example, corrosive environments require stainless steel. Installing fittings should be approached with care. Ensure threads are clean and free from debris. This can prevent leaks and prolong the life of the fittings.

During maintenance, regular inspections are essential. Look for signs of wear or corrosion. A small pit can lead to a big leak. Keep a maintenance log to track any changes. This can highlight patterns and problems over time. Sometimes, the best practices are overlooked. Rushing through checks might save time but could result in costly repairs.

Always follow the manufacturer's guidelines for installation and maintenance. If those guidelines are ignored, issues may arise. Not every fitting will perform the same way. Some may call for additional sealing or specialized tools. Understanding these nuances can prevent future issues. Thus, staying proactive in maintenance is key to ensuring longevity in your pressure fittings.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.