In the world of plumbing, the importance of choosing the right components cannot be overstated. Among these components, PVC valves play a crucial role in ensuring the efficiency and effectiveness of any plumbing project. According to renowned plumbing expert, Dr. Jane H. Miller, “Understanding the various types of PVC valves and their applications is essential for anyone looking to optimize their plumbing systems.” This statement resonates with both professionals and DIY enthusiasts as they embark on various plumbing tasks, highlighting the necessity of knowledge in this specialized area.

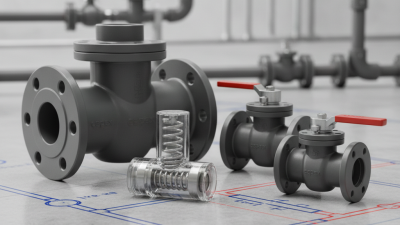

PVC valves are not only durable and cost-effective, but they also offer a wide range of functionalities that can cater to diverse plumbing needs. From controlling water flow to providing essential shut-off capabilities, these valves are indispensable. As we explore the top 10 PVC valves that every plumbing professional should know, it becomes evident that staying informed about the latest advancements and options in PVC valve technology is imperative for achieving successful plumbing outcomes. Understanding these tools will empower you to make informed decisions, maximizing the performance and reliability of your plumbing projects.

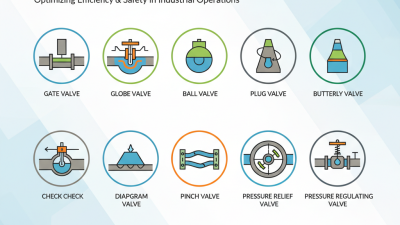

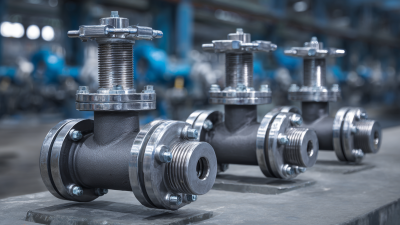

PVC valves play a crucial role in plumbing systems, offering a reliable and cost-effective solution for controlling the flow of water and other fluids. Understanding the different types of PVC valves, such as ball valves, gate valves, and check valves, can greatly enhance your plumbing projects. Each type serves a specific function, from shutting off flow to preventing backflow, making them essential components in both residential and commercial applications.

The importance of PVC valves extends beyond mere functionality; they also contribute to the overall efficiency and longevity of plumbing systems. Made from durable polyvinyl chloride, these valves resist corrosion and are less prone to leaks, making them ideal for various environments. Additionally, their lightweight nature facilitates easier installation, which can save time and labor costs during plumbing projects. As such, becoming familiar with the right types of PVC valves is key to ensuring robust and effective plumbing solutions.

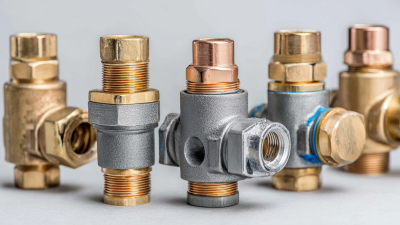

PVC valves are essential components in modern plumbing systems, celebrated for their remarkable durability and adaptability. One key characteristic of PVC valves is their resistance to corrosion compared to metal options, making them ideal for handling a wide range of fluids, including chemicals and wastewater. According to a 2022 report by the PVC Industry Association, PVC products exhibit a lifespan of over 50 years, significantly reducing the need for frequent replacements. This longevity is coupled with an impressive strength-to-weight ratio, enabling easier handling and installation, which is especially advantageous in large-scale plumbing projects.

Moreover, PVC valves are lightweight and exhibit low thermal conductivity, which means they maintain fluid temperature more effectively and prevent heat loss in hot water systems. These valves are also designed with minimal friction loss, ensuring smooth fluid flow, which can enhance the efficiency of plumbing systems. A comprehensive study by the American Society of Plumbing Engineers indicated that the use of PVC can reduce energy consumption by up to 30% in fluid transport applications. This not only supports environmental sustainability but also contributes to long-term cost savings for plumbing professionals and end-users alike.

When it comes to plumbing projects, selecting the right valves is crucial for ensuring optimal performance and longevity. PVC valves, in particular, have gained popularity due to their lightweight nature, corrosion resistance, and affordability. According to a report by the Plastics Industry Association, the demand for PVC products has been steadily increasing, with a projected growth rate of 5.2% annually, highlighting the significance of reliable plumbing solutions in both residential and commercial sectors.

One of the primary features to consider in PVC valves is their pressure rating. Most PVC valves are designed to withstand pressures ranging from 60 psi to 150 psi, making them suitable for various applications, including irrigation and drainage systems. Additionally, temperature resistance is another critical specification; standard PVC valves can operate effectively at temperatures up to 140°F. Furthermore, easy installation and maintenance are key advantages of PVC valves, as they typically require fewer tools and expertise than metal alternatives. Research indicates that integrating PVC valves into plumbing systems can lead to a decrease in installation time by approximately 30%, reinforcing their practicality for DIY enthusiasts and professionals alike.

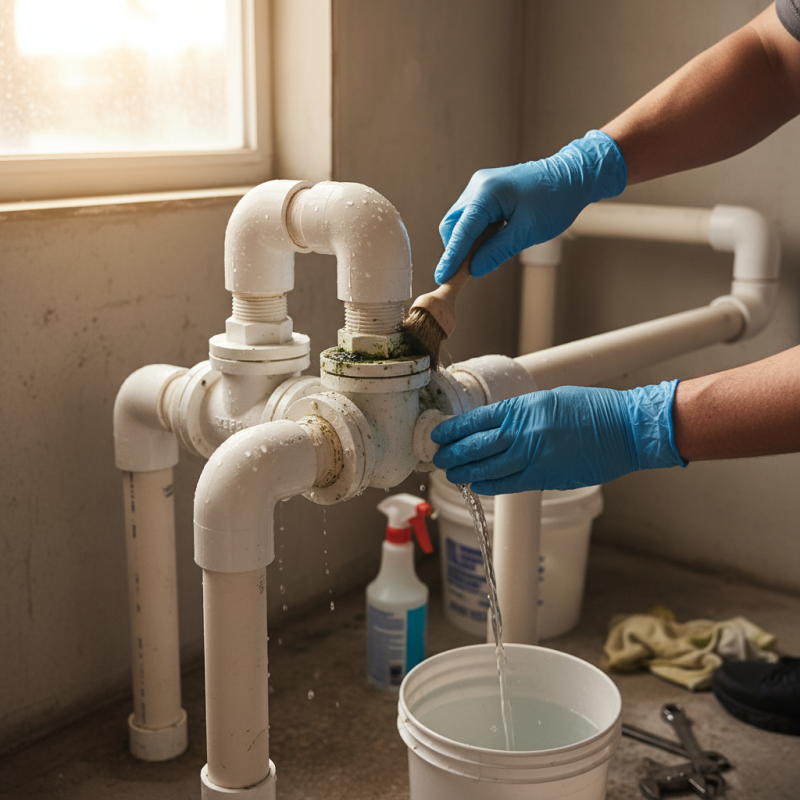

When installing PVC valves in plumbing projects, it is crucial to ensure a proper and secure fit to prevent leaks and ensure long-lasting performance. Begin by selecting the appropriate size and type of PVC valve for your specific needs. Always take time to measure the diameter of your pipes accurately. Before installation, prepare the pipe ends by cleaning and deburring them to eliminate any sharp edges or debris that could compromise the joint.

Use a suitable adhesive designed for PVC to bond the valve to the pipe. Apply the adhesive evenly on both surfaces and allow it to sit for a few moments as per the manufacturer's instructions to ensure optimal bonding. When joining the valve and pipe, twist them slightly to evenly distribute the adhesive and create a stronger seal. After assembly, allow adequate curing time before subjecting the joint to water pressure. This patience can prevent future leaks and enhance the reliability of your plumbing system. Proper installation techniques will ultimately preserve the integrity and efficiency of your plumbing projects.

Maintaining PVC valves is essential for ensuring their longevity and optimal performance in plumbing systems. Regular inspections can help identify issues such as leaks, blockages, or signs of wear and tear. It is important to check the valves for any visual damage or corrosion, especially in areas where the valves are exposed to UV light or harsh chemicals. Cleaning the valves periodically can prevent buildup that may hinder functionality, ensuring a consistent flow of water and reducing the risk of malfunction.

Troubleshooting PVC valves involves recognizing common problems and addressing them promptly. For instance, if a valve fails to open or close properly, it may be due to debris caught in the mechanism or a malfunctioning actuator. In these cases, disassembling the valve to clean it thoroughly may restore its operational integrity. Additionally, ensuring that all connections are secure can prevent leaks. If persistent issues arise, it may be worth considering replacement options, as even high-quality PVC valves have a finite lifespan and may eventually need to be substituted to maintain an effective plumbing system.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.