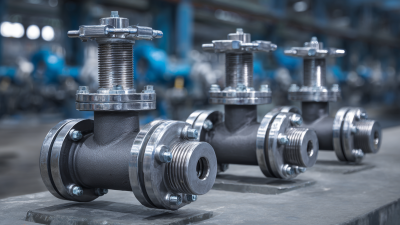

In the realm of fluid control systems, check valves play a pivotal role in ensuring efficiency and reliability. These essential devices, designed to allow fluid to flow in one direction while preventing backflow, are indispensable in various applications ranging from industrial processes to residential plumbing. Understanding the types and functionalities of different check valves is crucial for engineers, designers, and anyone involved in fluid management.

As we explore the "Top 10 Check Valves You Need to Know for Efficient Fluid Control," we will delve into the fundamental concepts that underpin these critical components, including their design variations and operational principles. This knowledge not only enhances system performance but also aids in the selection of the most suitable check valve for specific needs. Whether you are involved in the design of a new fluid system or seeking to optimize an existing one, gaining insight into these ten essential check valves can significantly impact the overall efficiency and effectiveness of your fluid control strategies.

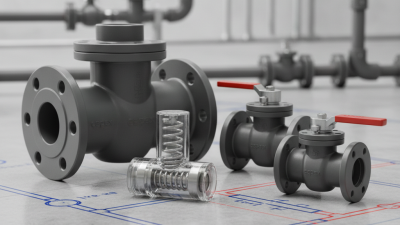

Check valves play a pivotal role in fluid control systems by allowing flow in one direction while preventing backflow. This functionality is crucial for maintaining system efficiency and protecting equipment. According to the Global Check Valve Market Report, the check valve industry is projected to reach an estimated value of $10 billion by 2026, driven primarily by increased investments in water and wastewater management systems. In various applications, ranging from industrial to residential, the presence of a check valve ensures that fluids move smoothly without the risk of contamination or damage to pumps and pipelines.

The importance of check valves extends beyond mere functionality; their design and material selection significantly influence the operational efficiency of fluid systems. Reports indicate that improper installation or the use of low-quality check valves can lead to pressure drops and energy loss of up to 30%. These losses not only escalate operational costs but may also result in greater wear and tear on system components. By understanding the critical role that check valves play, engineers and facility managers can make informed decisions to optimize their fluid control systems, thereby enhancing overall performance and reliability.

This chart illustrates the flow rates (in liters per minute) of the top 10 check valves commonly used in fluid control applications. Understanding the performance of these valves can help in selecting the right one for specific applications.

Check valves are critical components in fluid control systems, designed to permit fluid flow in one direction while preventing reverse flow. Their importance becomes evident in a variety of applications including water supply, wastewater management, and chemical processing. According to a report from the Global Market Insights, the check valve market is projected to grow at a CAGR of 5.5% from 2022 to 2030, driven by the rising demand for efficient fluid handling and the need for energy savings in industrial processes.

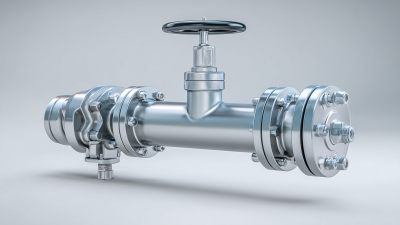

There are several types of check valves, each suited to particular applications. Swing check valves, for instance, utilize a disc that swings open with forward flow, making them optimal for low-pressure systems. In contrast, spring check valves use a spring mechanism to close, offering quicker response times and better sealing capabilities. A comprehensive study from the Fluid Control Institute indicates that incorporating the right type of check valve can significantly reduce energy costs by 20-30% in water distribution systems. Similarly, vacuum check valves are essential in applications where maintaining a vacuum is crucial, preventing backflow and ensuring process integrity.

Understanding the different types of check valves—including ball, diaphragm, and tilting disc variants—is vital for engineers and fluid dynamics professionals. Each type presents unique advantages that cater to specific operational conditions. For instance, ball check valves provide a reliable solution in turbulent flow conditions due to their streamlined design, which reduces pressure drop. Such insights underline the necessity for informed selection and application of check valves to enhance efficiency and longevity in fluid systems.

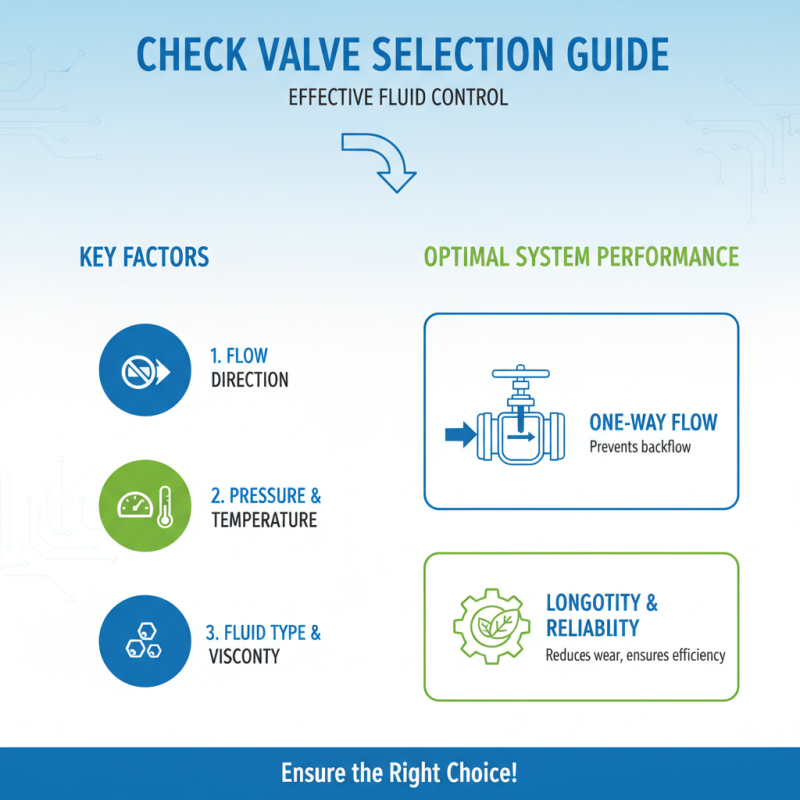

When it comes to selecting the right check valve for effective fluid control, several key factors should be considered to ensure optimal performance and longevity of your system. First, understanding the flow direction in your application is crucial. Check valves are designed to allow fluid to flow in only one direction, therefore, knowing whether your system functions primarily in forward or reverse flow can significantly influence your choice.

Material compatibility is another critical aspect to evaluate. Different fluids can react differently with various materials, so it’s essential to select a check valve constructed from materials resistant to corrosion or degradation caused by the fluids being transported. This step helps prevent leaks and system failures, ensuring a smoother operation.

**Tips:** Always consult the manufacturer's specifications and guidelines to clarify material properties. Additionally, consider the size and pressure rating of the valve, as choosing a valve that is too small or not rated for the system's pressure can lead to catastrophic failures. Installation orientation is also vital; ensure that the check valve is installed as per the manufacturer's recommendations to maintain efficiency and functionality.

When considering the use of check valves in fluid control systems, understanding the industry standards and regulations is crucial. The American Society of Mechanical Engineers (ASME) and the American National Standards Institute (ANSI) establish guidelines that ensure adequate safety and efficiency in valve applications. According to a 2022 report by the International Society of Automation, approximately 30% of fluid-related failures are attributed to improper valve selection or maintenance. Adhering to these standards not only enhances system performance but also complies with legal requirements that can affect operational licenses and insurance.

Tips for selecting the right check valve include evaluating the application’s pressure and temperature requirements, as well as material compatibility. Ensure the check valve design meets relevant standards, such as API 598 for valve inspection and test, which covers permissible leakage rates and performance benchmarks. Furthermore, it is essential to consider environmental regulations, such as those outlined by the Environmental Protection Agency (EPA), to avoid non-compliance and potential fines.

Incorporating these industry standards and best practices into your check valve selection process helps mitigate risks associated with fluid control systems. Regular audits and maintenance, as suggested by the 2023 Fluid Control Safety Compliance Report, emphasize the importance of keeping check valves in optimal condition to prevent costly downtime and ensure regulatory compliance.

| Check Valve Type | Application | Material | Pressure Rating | Standards Compliance |

|---|---|---|---|---|

| Swing Check Valve | Water and Wastewater | Cast Iron | 150 PSI | API 609 |

| Lift Check Valve | Steam and Gas | Stainless Steel | 300 PSI | ASME B16.34 |

| Ball Check Valve | Oil and Gas | Brass | 150 PSI | AWWA C508 |

| Duckbill Check Valve | Sewage Applications | Rubber | N/A | ASTM D2000 |

| Silent Check Valve | HVAC Systems | PVC | 150 PSI | ISO 9705 |

| Diaphragm Check Valve | Water Treatment | EPDM | 60 PSI | FDA Compliant |

| Piston Check Valve | Hydraulic Systems | Aluminum | 250 PSI | SAE J518 |

| Check Valve with Flange | Pipeline Services | Cast Steel | 600 PSI | API 6D |

| Tide Check Valve | Drainage Systems | Polyethylene | N/A | BS EN 1105 |

Proper maintenance of check valves is crucial for ensuring optimal performance in fluid control applications. According to a report by the International Water Association, poorly maintained valves can lead to pressure drops, leaks, and even system failures, which can increase operational costs by up to 30%. Regular inspections should be conducted to identify signs of wear and tear or corrosion, which can compromise the integrity of the valve. The recommended maintenance frequency is at least once a year, but this may vary based on the fluid's nature, pressure conditions, and the specific environment.

Implementing best practices for maintenance can extend the lifespan of check valves significantly. The American Society of Mechanical Engineers (ASME) suggests using non-destructive testing methods to assess valve condition without causing damage. Additionally, lubricating the valve components periodically helps prevent sticking and ensures smooth operation. In high-pressure systems, it is advisable to test the valve’s sealing performance regularly, as a failure to seal can lead to backflow and system inefficiency. By adhering to these best practices, facility managers can optimize performance, maintain safety standards, and ultimately reduce downtime and repair costs.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.