Irrigation valves play a crucial role in modern agriculture, directly impacting water efficiency. According to a recent report by the Irrigation Association, optimizing irrigation can reduce water usage by up to 30%. This statistic highlights the importance of using the right irrigation valves in farming practices today.

Expert Jane Mitchell, a leading figure in irrigation technologies, states, "The choice of irrigation valves can significantly affect crop yield and water sustainability." Her insight emphasizes the need for farmers to carefully consider the valves they employ. Poor choices can lead to water wastage and increased costs.

Many farmers overlook the variety of irrigation valves available. Each type has unique benefits and drawbacks. For example, manual valves may save money initially but consume more time and labor. In contrast, automatic valves offer convenience but at a higher cost. Understanding these aspects is essential for improving irrigation methods and achieving better overall results.

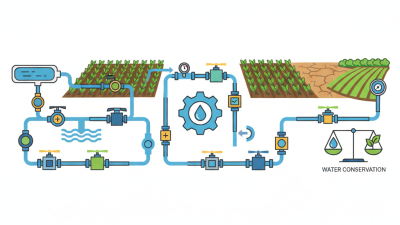

Irrigation valves play a crucial role in agriculture. They help control water flow, ensuring plants receive adequate hydration. Without proper regulation, crops may suffer from overwatering or underwatering. These missteps can lead to reduced yields and poor quality produce.

Consider this tip: check your irrigation system regularly. A simple inspection can prevent major issues. Look for leaks and blockages. Regular maintenance is key. Also, be mindful of the size and type of valve used. Not all valves suit every irrigation system. Choosing the right one matters greatly for efficiency.

Farmers often overlook the significance of irrigation valves. It’s easy to forget such small components. However, their impact is substantial. A malfunctioning valve may disrupt water supply. This could stress plants, leading to slower growth. Take time to assess and understand your irrigation needs. Sometimes, less is more. Investing in the right equipment pays off in the long run.

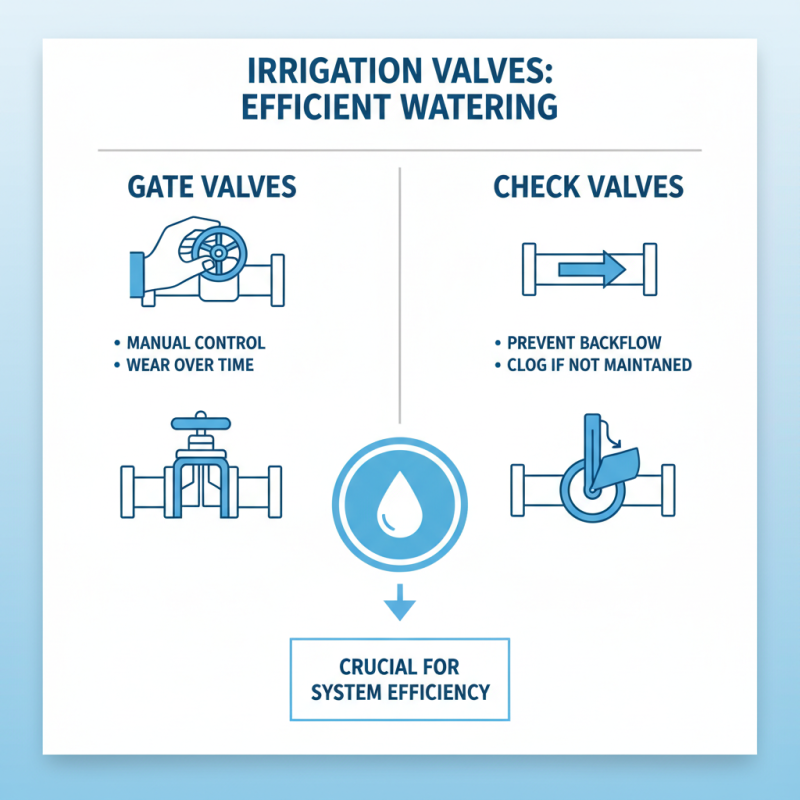

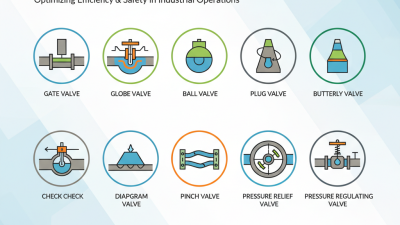

Irrigation valves play a crucial role in maintaining an efficient watering system. There are various types of valves, each designed for specific functions. Gate valves, for instance, offer manual control. They are straightforward but can wear out over time. Check valves, on the other hand, prevent backflow. This ensures water only moves in one direction. However, they can clog if not maintained properly.

Another essential type is the solenoid valve. These are electronically controlled. They allow for automation in your irrigation system. But their dependency on electric power can be a drawback. Ball valves are durable and provide excellent flow control. Yet, their installation can be tricky. It’s vital to consider how each type fits into your overall irrigation plan. Finding the right valve requires careful thought. Using the wrong one can lead to leaks or wasted water. Evaluating your specific needs is key.

When selecting irrigation valves, several key features are crucial. The flow rate is one of the primary considerations. A study from the Irrigation Association indicates that choosing valves with optimal flow rates can enhance system efficiency by up to 20%. This is vital for farmers who want to minimize water waste and costs.

Another significant factor is compatibility with various irrigation systems. Many farmers face challenges when valves do not integrate well with their existing setups. Compatibility can influence the longevity of the irrigation system. According to industry reports, around 30% of irrigation failures are due to incompatibility issues.

Pressure rating also matters. Valves must withstand the pressures of the irrigation system. Low-quality valves can malfunction under high pressure, leading to costly repairs. It’s essential to choose valves with appropriate pressure ratings for reliable performance. Remember, not every valve is perfect. Some may leak or fail earlier than expected. Farmers should regularly inspect their equipment to identify issues early.

This chart illustrates the flow rate (GPM) of the top 10 irrigation valves, highlighting key considerations when choosing the right valve for your irrigation system.

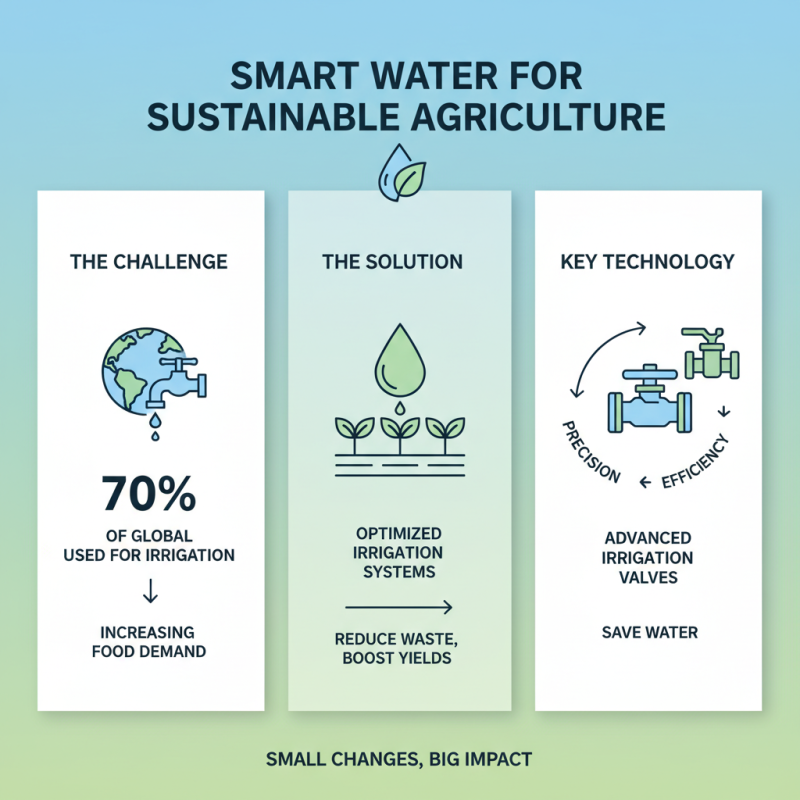

Efficient water management is essential for sustainable agriculture. With the increasing demand for food, optimizing irrigation systems is crucial. Reports estimate that irrigation accounts for 70% of global freshwater use. Choosing the right valves can significantly reduce water waste and improve crop yields.

Several types of valves are crucial. For instance, solenoid valves offer automation, as they can be controlled electronically. This feature allows precise timing for irrigation, conserving water. Additionally, pressure relief valves help in managing water pressure, preventing leaks or damages in the system. Research shows that well-managed irrigation systems can reduce water use by up to 30%.

However, not all valves are created equal. Some may corrode quickly, leading to costly repairs. Regular maintenance is often overlooked, which can result in inefficiencies. Understanding the options available is vital to ensure that farmers invest wisely. Balancing costs with quality can be challenging. Inadequate knowledge can lead to poorly functioning systems, increasing waste and expenses.

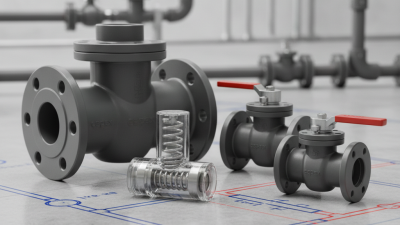

Maintaining irrigation valves is crucial for optimal performance. Regular inspections are essential. Check for leaks and signs of wear. Research indicates that proper maintenance can extend the lifespan of these valves significantly, sometimes by up to 25%.

Cleaning is another key aspect. Dirt and debris can clog valves and disrupt flow. It's recommended to clean valves at least twice a year. Some experts suggest monthly checks in high-use seasons.

Replacing worn parts is also important. Many valves can show wear after just a few irrigation cycles. However, some users overlook this until major failures occur. Ignoring early signs can lead to costly repairs. Keeping a maintenance log can help track these issues and ensure timely interventions.

| Valve Type | Material | Pressure Rating (psi) | Typical Usage | Maintenance Tips |

|---|---|---|---|---|

| Ball Valve | PVC | 150 | Residential irrigation | Regularly check for leaks and debris. |

| Gate Valve | Brass | 200 | Mainline control | Lubricate threads and check operation regularly. |

| Check Valve | PVC | 100 | Prevent backflow | Inspect for clogs and replace seals when needed. |

| Pressure Relief Valve | Bronze | 150 | System protection | Test functionality periodically. |

| Solenoid Valve | Plastic | 120 | Automatic irrigation systems | Clean coils and replace damaged wires. |

| Diaphragm Valve | Rubber | 100 | Flood control | Check seals for wear and replace if necessary. |

| Angle Valve | Steel | 150 | Garden hoses and faucets | Inspect for rust and corrosion. |

| Float Valve | Plastic | 80 | Water level control | Clean regularly to prevent sticking. |

| Irrigation Valve Box | Polyethylene | N/A | Protection for valves | Keep clear of debris and inspect regularly. |

| Anti-Siphon Valve | PVC | 100 | Prevent contamination | Monitor for clogs and clean if necessary. |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.