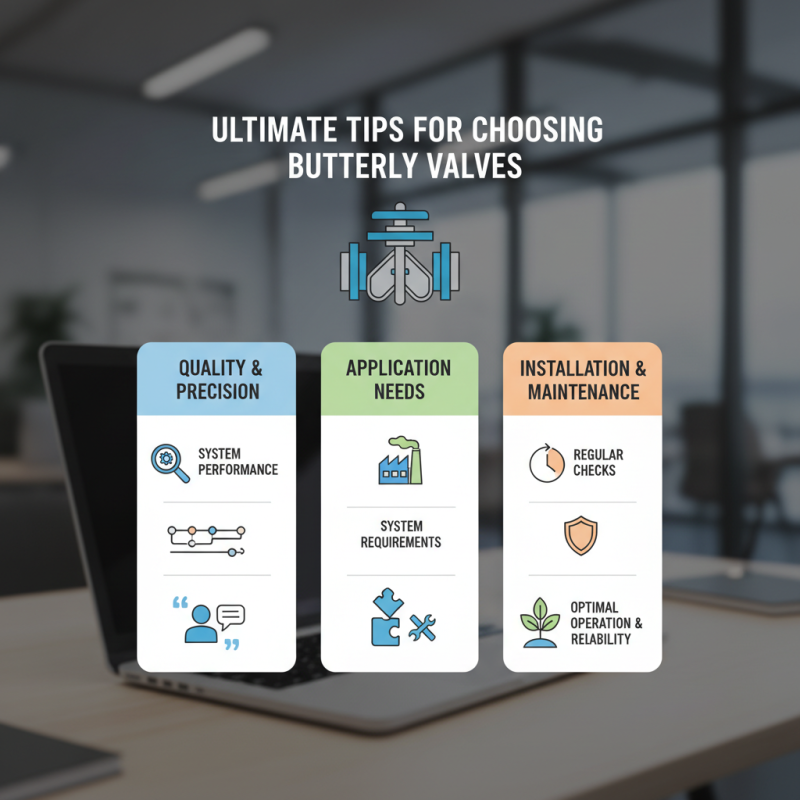

When considering the selection of Cepex butterfly valves, it is crucial to understand their unique features. Industry expert John Smith emphasizes, "Quality and precision in butterfly valves can significantly affect system performance." This highlights the importance of careful evaluation.

Cepex butterfly valves are designed for efficiency. However, not all models fit every application. Assessing the needs of your system is vital. Many overlook the specific requirements. This can lead to costly mistakes or inefficiencies.

Moreover, installation and maintenance play critical roles in performance. A common error is neglecting regular checks. This oversight can diminish the valve's lifespan and effectiveness. By understanding these factors, you can make a more informed choice. Choosing the right Cepex butterfly valves ensures optimal operation and long-term reliability.

Cepex butterfly valves play an essential role in various industries. These valves are designed to regulate the flow of liquids and gases. They consist of a disc that rotates to open or close the flow path. Their compact design allows for easy installation and maintenance. This is a vital aspect for many operators.

These valves are commonly used in water treatment, chemical processing, and HVAC systems. In water management, they help control the water flow effectively. Their reliability ensures that systems function optimally in various environments. However, users sometimes overlook the importance of proper sealing. A poor seal can lead to leaks, which may cause operational inefficiencies.

When selecting a butterfly valve, consider the application. Different materials may be needed for corrosive substances. Also, evaluate the size and pressure ratings to match your system's specifications. Some users may underestimate the need for regular inspections. Ensuring proper maintenance can enhance the valve's longevity and performance.

| Dimension | Material | Size Range | Pressure Rating | Temperature Range | Applications |

|---|---|---|---|---|---|

| DN50 - DN1200 | Cast Iron / Stainless Steel | 2" - 48" | PN10 - PN40 | -10°C to 120°C | Water Treatment / HVAC / Industrial |

| DN100 - DN1500 | PVC / PP | 4" - 60" | PN6 - PN16 | 0°C to 60°C | Chemical Processing / Aquaculture |

| DN80 - DN1400 | Ductile Iron / Aluminum | 3" - 56" | PN16 - PN25 | -20°C to 80°C | Fire Protection / Oil and Gas |

When selecting a butterfly valve, several key features come into play. The size of the valve is crucial. It must match your system's configuration. This ensures proper flow and prevents leakage. Also, consider the material. Different environments require different materials. For instance, corrosive environments demand high-quality materials to last longer.

Another aspect to reflect on is the valve's performance. Look at the pressure rating and temperature range. These factors determine how the valve will operate under specific conditions. Sometimes, a valve may appear perfect but fail under pressure. Always check the specifications carefully.

Lastly, think about the ease of maintenance. Some valves require more diligent upkeep than others. This can add to the overall cost and downtime. A less complex design may simplify repairs, allowing for quicker fixes. Choosing a valve is not just about finding the right fit, but also ensuring long-term effectiveness. There's always room for scrutiny in the decision-making process.

This chart illustrates the key features and their importance when selecting Cepex Butterfly Valves. The features considered are 'Durability', 'Flow Control', 'Ease of Maintenance', and 'Cost Efficiency'.

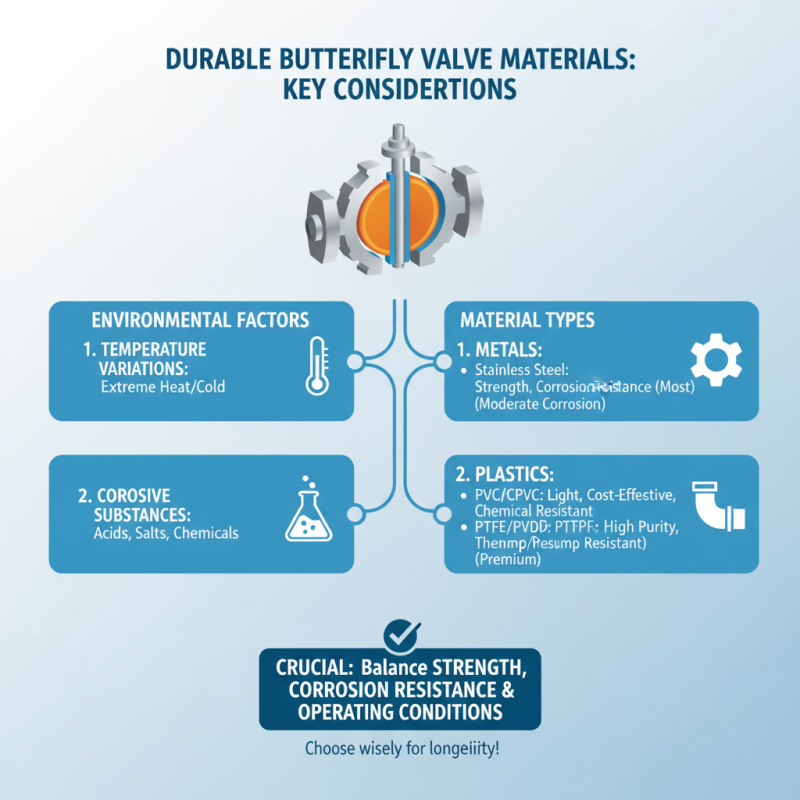

When selecting materials for durable butterfly valves, it's crucial to consider the environment. Think about temperature variations and corrosive substances. Some materials may resist rust well but could fail under extreme temperatures. The choice between metal and plastic often needs careful evaluation. Metal options like stainless steel offer strength, while PVC can be lighter and more cost-effective.

Also, consider the valve's application. For water systems, choose materials designed to handle moisture. For chemical processes, resistant materials are a must. Sometimes, materials that seem suitable may actually degrade faster than expected. Conducting thorough research can prevent future problems.

Choosing the right material is not just about cost. Suppose you opt for low-quality plastic; it might save money initially but lead to leaks. Potential risks may arise from improper selections. Reflect carefully on your choices to find the ideal material for your needs. Each decision carries weight, impacting durability and performance.

When it comes to installing butterfly valves, attention to detail is crucial. Proper alignment is key for optimal operation. Ensure the valve is parallel to the pipeline. Misalignment can lead to leaks or equipment failure, which can be costly. Remember, each installation site may present different challenges.

Maintenance is equally important. Regular inspections help identify issues before they escalate. Look for signs of wear or corrosion. Clean the valve often to prevent buildup that could hinder performance. It’s a good idea to keep detailed records of maintenance actions. This helps track the valve’s condition over time.

Another tip: ensure that the actuators function smoothly. They should respond quickly to controls. If there is any delay, investigate immediately. Regular lubrication of moving parts can enhance performance. Adapting your approach based on real-world feedback will lead to better long-term outcomes for your system.

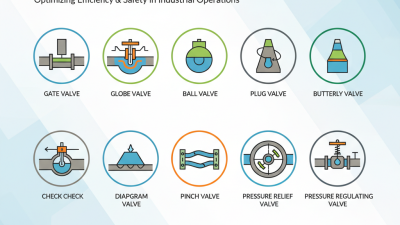

When comparing butterfly valves with other valve types, several factors should be considered. Butterfly valves are compact and lightweight, making installation easier. They allow for quick on/off control with minimal resistance to flow. This can be advantageous in many applications, especially where space is limited.

However, they are not always the best choice. In high-pressure situations, other valves may perform better. For example, ball valves often provide a tighter seal. They are preferred in systems requiring a complete shut-off. Butterfly valves can struggle with this, especially as they age. Regular maintenance is key to ensuring their longevity and functionality.

When selecting a valve, consider the medium it will handle. Some fluids may cause wear or corrosion over time. It's worth reflecting on your specific needs. Think about pressure ratings and the operating environment. A butterfly valve might seem suitable initially, but reevaluation is crucial. Not every situation is cut and dry; understanding each valve's strengths and weaknesses is essential.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.