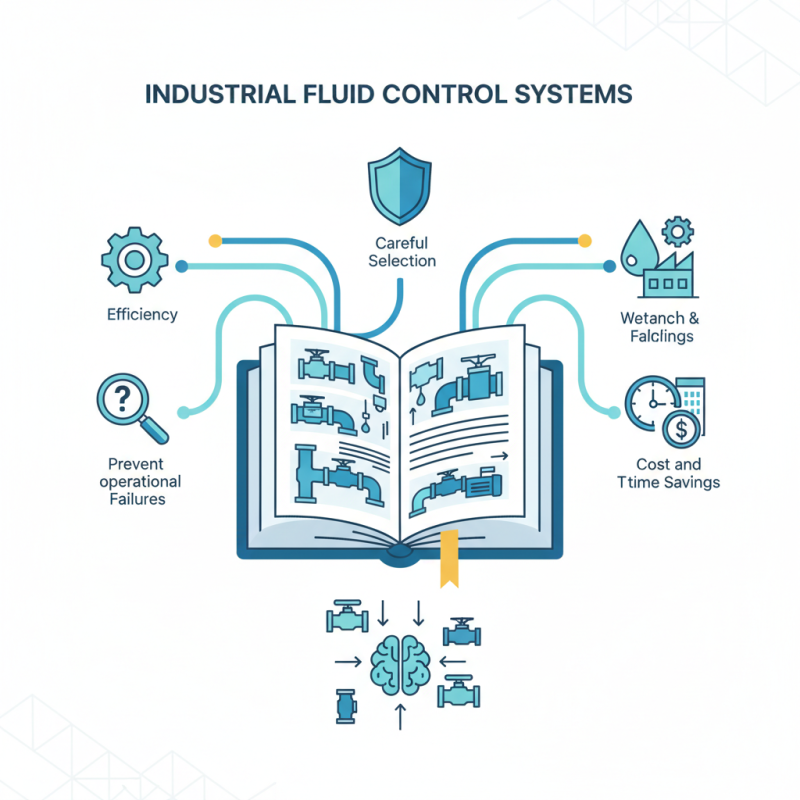

In the world of fluid control systems, the "cepex valves catalogue" plays a vital role. This catalogue serves as a comprehensive guide for engineers and designers. It presents various valve types and their specifications. Users can easily find essential information like size, pressure ratings, and materials.

Having a detailed catalogue is crucial for system efficiency. Fluid control systems depend on precise valve selection. An ill-suited valve can lead to operational failures. Therefore, engineers must refer to the cepex valves catalogue carefully. Mistakes in selection are expensive and time-consuming.

Beyond just specifications, the catalogue offers insights into application areas. Users discover how different valves function in diverse systems. It highlights the importance of choosing the right valve for specific conditions. However, navigating this information can be overwhelming. Reflecting on the choices in the catalogue helps in making informed decisions.

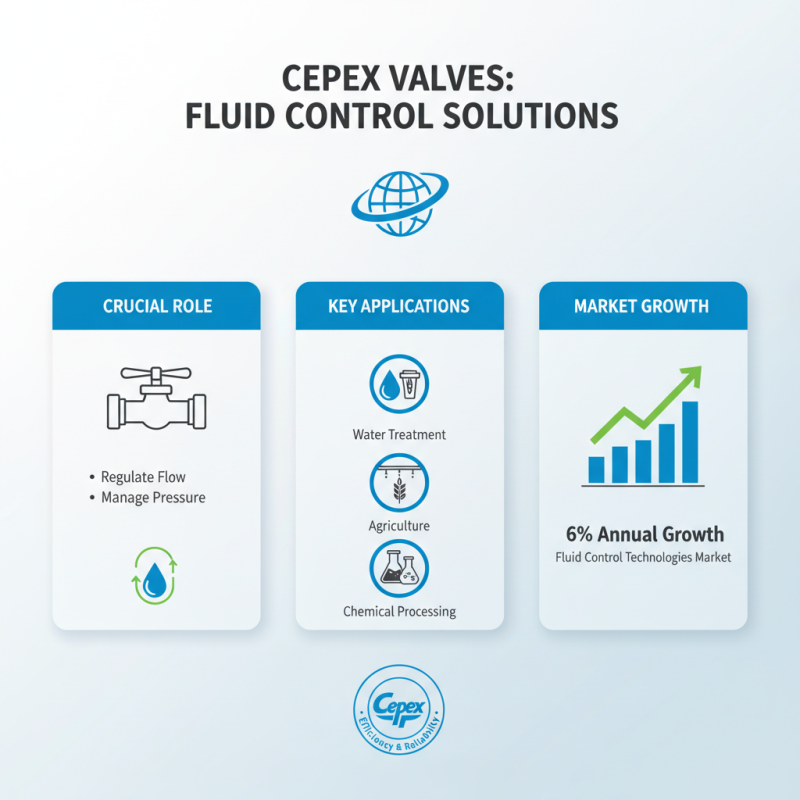

Cepex valves play a crucial role in fluid control systems. These valves regulate flow and pressure within various applications. They are vital in industries like water treatment, agriculture, and chemical processing. According to recent industry reports, fluid control technologies are projected to grow by 6% annually. This underscores the increasing demand for efficient and reliable valve systems.

Proper functionality is essential. Poorly designed valves can lead to leaks and system failures. Such issues can result in costly downtime. In fact, maintenance costs can account for up to 30% of operational expenses. Quality valves help reduce these costs by ensuring smooth operations. However, not all valves meet industry standards, emphasizing the need for a dependable catalogue.

Moreover, there is a noticeable gap in awareness regarding the importance of these components. Many users overlook the significance of selecting the right valve for their system. This oversight can hinder optimal performance. Technical insights in a well-structured catalogue can bridge this gap. Comprehensive information helps users make informed choices. Understanding specifications, compatibility, and benefits strengthens fluid control strategies.

The Cepex Valves Catalogue serves a critical role in fluid control systems. It provides extensive details on various valve types, materials, and specifications. Users can find information on dimensions, pressure ratings, and applications. This information is essential for engineers when selecting the right valve for their systems. It's not just a list; it's a guide that ensures efficiency and reliability.

One notable aspect is the range of options available. While it may seem overwhelming, this variety allows for tailored solutions. Yet, users must reflect on their specific needs. Some may choose a valve that is not ideal. Identifying the correct valve means considering not just specifications but also the unique characteristics of each fluid. This approach can significantly impact system performance.

The catalogue also includes installation guidelines and maintenance tips. Proper installation is crucial for longevity. However, some users might overlook this information, leading to potential issues. Reflecting on past experiences can highlight the importance of adhering to these guidelines. Ultimately, the catalogue is a valuable resource, but it requires thoughtful engagement.

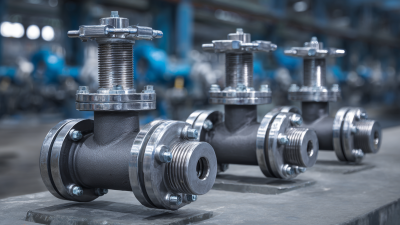

In fluid control systems, the Cepex valves catalogue serves as a vital resource. It outlines the key features and specifications of various valve types. This includes materials, sizes, and performance ratings. Understanding these details allows engineers to make informed decisions for their projects.

One notable feature is the pressure rating, which can reach up to 16 bar in many designs. This ensures reliable operation in high-demand environments. Furthermore, the catalogue emphasizes chemical resistance. Many valves are constructed from robust materials that withstand corrosive liquids.

However, not all valves may perform as expected under heavy loads. There are reports indicating that some models may experience failures sooner than anticipated. Therefore, it is crucial to check real-world performance data in conjunction with catalogue specifications. Additionally, fit and compatibility issues arise in diverse applications. This necessitates a thorough review of specifications to prevent operational challenges.

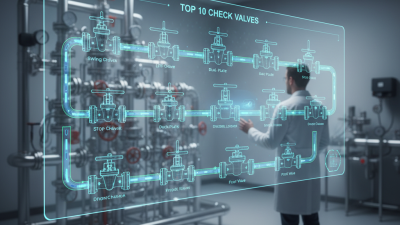

The chart above illustrates the flow efficiency of various types of valves used in fluid control systems. Each valve type demonstrates different performance levels, impacting the selection process based on system requirements and applications. Ball valves generally offer the highest efficiency, making them a popular choice in many fluid control situations.

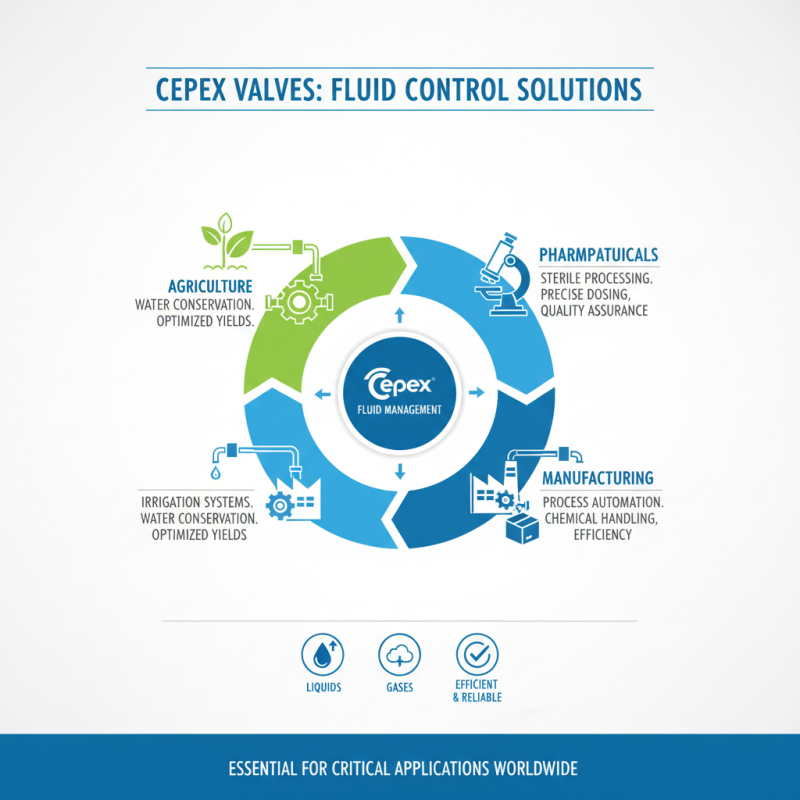

Cepex valves play a crucial role in fluid control systems across various industries. These valves ensure the efficient management of liquids and gases, which is vital in fields like agriculture, pharmaceuticals, and manufacturing. In agriculture, for example, they regulate water flow in irrigation systems. Precise control can lead to better crop yields while conserving water. This is essential in regions facing water scarcity.

In the pharmaceutical industry, these valves help maintain sterile environments. They prevent contamination during the handling of sensitive fluids. The right valve can make or break the safety of medical products. Industries need to be aware of the specifications when selecting these valves.

Tips: Always consider the pressure ratings and chemical compatibility of the valves. Small mistakes in selection can lead to expensive failures. Regular inspections are also necessary. Monitoring the performance of these valves can save time and reduce risks. One overlooked aspect is the installation process. Improper installation can hinder performance, regardless of the valve quality.

Cepex valves play a crucial role in fluid management systems. They help regulate and control the flow of liquids in various applications. Their robust construction ensures reliability, even in challenging environments. This makes them suitable for industries such as agriculture, manufacturing, and water treatment. A well-designed valve can enhance efficiency and reduce waste significantly.

Using Cepex valves comes with multiple benefits. One notable advantage is their resistance to corrosion. This feature is vital for systems dealing with aggressive fluids. Additionally, their lightweight materials simplify installation and maintenance tasks. However, users may sometimes overlook the importance of selecting the right size and type of valve. An improper choice could lead to system inefficiencies or failures.

Tips: Regularly inspect your valve performance. Look for signs of wear or leaks. Ensuring proper maintenance can save costs in the long run. When in doubt, consult an expert for guidance on valve selection. Balancing quality and cost is vital, yet easy to overlook. Always prioritize system compatibility to avoid complications later on.

| Feature | Description | Benefits |

|---|---|---|

| Durability | Designed to withstand harsh conditions and prolonged use. | Lower replacement costs and improved longevity. |

| Versatility | Compatible with various fluids including chemicals and gases. | Increased usability across multiple applications. |

| Easy Installation | Simple design allows for quick setup and integration. | Reduces downtime and labor costs. |

| Flow Control | Precise regulation of flow rates for optimal performance. | Enhances system efficiency and safety. |

| Custom Solutions | Option to customize valves for specific operational needs. | Tailored solutions improve functionality and performance. |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.