In today’s rapidly evolving plumbing and industrial sectors, the significance of pressure fittings cannot be overstated. These components are pivotal in ensuring fluid transfer systems operate efficiently and safely in a variety of applications, from residential plumbing to large-scale industrial operations. As industry expert Dr. Jonathan Lee, a recognized authority in fluid dynamics, aptly stated, “Pressure fittings are the backbone of reliable and secure piping systems.” His insights highlight the fundamental role these fittings play in maintaining system integrity and preventing leaks, which can lead to costly damages and safety hazards.

Pressure fittings serve as essential connectors that withstand high-pressure environments, making them crucial for diverse industries including oil and gas, pharmaceuticals, and manufacturing. The correct use of pressure fittings not only enhances the durability and efficiency of the systems they are a part of, but also contributes to overall operational safety. As we delve deeper into the various aspects of pressure fittings, we will explore their types, applications, and the reasons they are indispensable to modern plumbing and industrial frameworks. Each fitting is designed to meet specific pressures and temperatures, underscoring the importance of selecting the right fitting for any given application. Understanding these components is key to ensuring functional and safe operations.

Pressure fittings play a critical role in plumbing systems, ensuring secure and leak-free connections that are vital for both residential and commercial applications. According to the American Society of Plumbing Engineers (ASPE), improper fittings can lead to significant issues, including water leakage and system failures, which not only waste water but also incur high repair and maintenance costs. Research indicates that approximately 20% of plumbing leaks are attributed to faulty fittings, highlighting their importance in safeguarding the integrity of plumbing infrastructure.

In industrial applications, the need for reliable pressure fittings becomes even more pronounced. The International Society of Automation (ISA) reports that around 40% of industrial equipment failures stem from weak or unreliable connections in fluid systems. These failures can result in downtime and severe operational disruptions, costing businesses thousands of dollars. As industries continue to rely on complex piping systems, the use of durable and correctly installed pressure fittings is essential for maintaining efficient operations and preventing costly leaks or failures. The right pressure fittings not only enhance system reliability but also contribute to compliance with safety and environmental regulations.

| Dimension | Material | Pressure Rating (psi) | Application |

|---|---|---|---|

| 1/2 inch | Copper | 1000 | Residential plumbing |

| 3/4 inch | Brass | 600 | Hydraulic systems |

| 1 inch | PVC | 320 | Irrigation systems |

| 1-1/4 inch | Stainless Steel | 1500 | Industrial applications |

| 2 inch | Galvanized Steel | 300 | Fire protection systems |

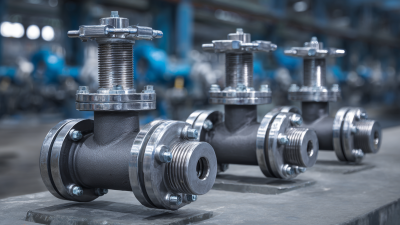

Pressure fittings play a crucial role in industrial applications by facilitating the safe and efficient transfer of fluids and gases under high pressure. These fittings are designed to withstand extreme forces and prevent leaks, ensuring that systems operate reliably. In industries such as oil and gas, chemical processing, and water treatment, the integrity of pressure fittings is paramount. They provide the necessary connections between pipes, valves, and other equipment, enabling the seamless functioning of complex systems while minimizing the risk of accidents and environmental hazards.

Moreover, the choice of pressure fittings impacts the overall efficiency of industrial processes. High-quality fittings reduce turbulence and pressure drops within the system, promoting better flow rates and energy savings. They also contribute to maintenance efficiency, as durable fittings require less frequent replacements and repairs.

This is particularly important in large-scale operations where downtime can lead to significant financial losses. In summary, pressure fittings are not merely connectors; they are vital components that enhance the reliability and efficiency of industrial systems. Their role cannot be overstated in maintaining operational excellence across various sectors.

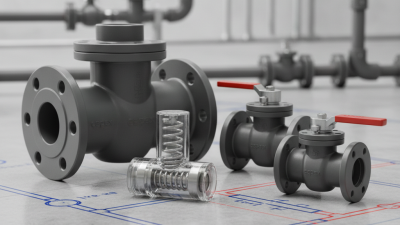

Pressure fittings are crucial components in both plumbing and industrial applications, designed to ensure secure and leak-free connections between pipes. These fittings come in various types, each tailored to specific needs and materials. For instance, compression fittings are widely used in residential and commercial plumbing due to their ease of installation and reliability. According to industry reports, the global compression fittings market is expected to reach USD 2.5 billion by 2025, highlighting their importance in maintaining efficient fluid transport systems.

Another popular pressure fitting type is the socket weld fitting, commonly utilized in high-pressure and high-temperature applications in industries like oil and gas. These fittings allow for a seamless connection without the need for additional parts, streamlining the assembly process. The American Society of Mechanical Engineers (ASME) emphasizes that the failure rates for poorly applied fitting connections can exceed 60%, underscoring the critical role of choosing the right pressure fittings. Moreover, butt-weld fittings offer robust durability for heavy-duty applications, making them invaluable in sectors requiring strong pressure retention, such as chemical processing.

Understanding the diverse applications and merits of these pressure fittings can significantly enhance system performance and safety. As industries evolve, innovation in fitting designs continues to flourish, addressing the growing demand for more efficient and reliable plumbing solutions.

Pressure fittings play a crucial role in plumbing and industrial applications primarily due to their effectiveness in preventing leaks. These specialized connectors are designed to withstand high-pressure environments, ensuring a secure and tight seal. The robust construction of pressure fittings minimizes the chance of wear and degradation over time, which is particularly important in systems that transport liquids or gases. By using pressure fittings, professionals can significantly reduce the risk of leaks that could potentially lead to costly repairs and downtime.

Another key benefit of utilizing pressure fittings is their versatility across different materials and setups. Whether used in metal, plastic, or composite systems, pressure fittings can accommodate a variety of applications, making them an ideal choice for diverse industrial environments. Their design facilitates easy installation and maintenance, allowing for quick replacements without the need for extensive modifications. This flexibility not only enhances efficiency but also ensures that systems remain operational without significant interruptions, demonstrating the vital role pressure fittings play in leak prevention and overall system reliability.

In plumbing and industrial applications, the installation and maintenance of pressure fittings play an integral role in ensuring system reliability and safety. Pressure fittings must be installed correctly to handle the stresses of high-pressure environments, which are commonplace in many industrial processes. A report from the American Society of Mechanical Engineers (ASME) indicates that improper installation can lead to a 30% increase in the risk of system failures, highlighting the necessity for skilled technicians to execute precise installations. This includes ensuring proper alignment and torque specifications to prevent leakage and potential catastrophic failures.

Regular maintenance is equally crucial for pressure fittings, as neglected fittings can degrade over time due to factors such as corrosion, vibration, and thermal expansion. The National Institute of Standards and Technology (NIST) emphasizes that routine inspections and timely maintenance can extend the life of pressure fittings by up to 40%. Implementing a proactive maintenance schedule not only enhances safety but also reduces costly downtime in industrial settings, where system reliability is paramount. Therefore, adherence to best practices in installation and ongoing maintenance is essential for maximizing the performance and longevity of pressure fittings in various applications.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.