Plastic valves are crucial components in various modern industries. These valves play a significant role in controlling the flow of fluids and gases. Their lightweight design offers easy installation and maintenance. This accessibility often leads to improved efficiency in many operations. Industries such as chemical processing, food and beverage, and pharmaceuticals increasingly rely on plastic valves.

Their resistance to corrosion is a key advantage. While metal valves may deteriorate, plastic valves withstand harsh environments. However, concerns about durability occasionally arise. Some wonder if plastic valves can endure extreme conditions. Despite these doubts, ongoing advancements in material science boost their reliability.

The versatility of plastic valves surprises many. They are available in different shapes and sizes. These options allow customization for specific industrial needs. The reality is that not all plastic valves are created equal. Companies must choose wisely to ensure they meet their requirements. In the end, plastic valves represent a modern solution, yet they demand careful consideration.

Plastic valves play a crucial role in modern fluid control systems. Their lightweight nature allows for easy installation across various industries. In chemical processing, for instance, plastic valves resist corrosion. This capability is vital when handling aggressive substances. As safety becomes increasingly important, these valves reduce the risk of leaks.

In water treatment facilities, plastic valves enhance efficiency. They can be adapted to different pressure levels and flow rates. This flexibility supports diverse applications, from municipal systems to industrial usage. However, some may question their durability compared to metal valves. While plastics are robust, they can wear down under extreme conditions. Regular inspection is needed to ensure they function effectively.

Further, the cost-effectiveness of plastic valves cannot be overlooked. They often require less maintenance, saving companies time and money. Yet, there is a perception that lower cost means lower quality. This belief may lead to hesitation in certain industries. Educating teams about the advantages of modern plastic materials is essential. The balance between performance and cost remains a key consideration in today's industrial landscape.

The global market for plastic valves is rapidly expanding. Many industries now rely on these valves for their operations. Plastic valves are lightweight and corrosion-resistant. They meet the demands of various environments, from water treatment plants to chemical processing facilities. These characteristics make plastic valves an attractive option for engineers.

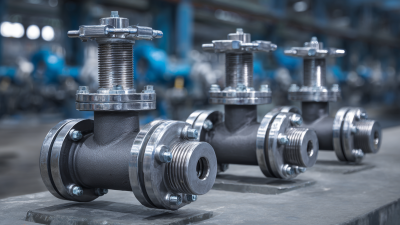

Market trends indicate a significant uptick in the use of plastic valves. The automotive sector is embracing them due to their efficiency and lower weight. The chemical industry also benefits from their durability. However, challenges remain. Some may question how well these valves perform under extreme conditions. It’s crucial to evaluate both pros and cons.

Many companies are investing in research to improve these valves. Enhanced designs may lead to better performance. Innovators are looking for sustainable materials as well. The goal is to reduce environmental impact. Yet, the journey is not without obstacles. Balancing cost and efficiency remains a challenge for manufacturers.

Plastic valves play a crucial role in modern industries. Their benefits include

cost savings, corrosion resistance, and weight reduction. According to a recent industry report,

companies can save up to 30% in materials when switching from metal to plastic valves. This

cost efficiency is particularly vital for industries facing tight budgets.

Corrosion resistance is another major advantage. Unlike metals, plastics do not corrode when exposed to harsh

chemicals. A study showed that using plastic valves can extend the lifespan of piping systems by up to

40%. This longevity minimizes maintenance costs and enhances reliability. Many businesses have noted

a decrease in downtime due to leaks or failures.

Weight reduction also benefits industries. Plastic valves are significantly lighter than their metal counterparts.

This weight difference simplifies installation and reduces transportation costs. In logistics, for instance, lighter materials can lead to lower

shipping fees. However, some companies still hesitate to fully embrace plastic, often fearing it may not handle high-pressure situations as well as

metal. The balance of adopting newer materials while addressing these concerns remains a pressing issue.

Plastic valves play a crucial role in several industries today. In the chemical sector, they are favored for their corrosion resistance. They handle aggressive substances with ease. This capability reduces risks and enhances safety. The lightweight design helps with easier installation and maintenance.

Water treatment facilities also rely heavily on plastic valves. They efficiently manage flow rates and ensure system integrity. Their non-reactive nature ensures that the water treated remains pure. However, some facilities overlook the importance of regular checks. Regular maintenance can prevent costly interruptions.

In the oil and gas sector, plastic valves are increasingly common. They provide reliable sealing under high pressures. The ability to resist chemical erosion is vital. However, users should keep an eye on performance over time. Sometimes, wear and tear can go unnoticed, leading to failures.

**Tips:** Always evaluate the specific needs of each application. Not all plastic valves are the same. Regularly inspect valves for signs of damage or wear.

This chart illustrates the percentage usage of plastic valves across key industries, highlighting their essential role in manufacturing, water treatment, and oil & gas sectors.

Emerging technologies are transforming the manufacturing of plastic valves. Recent studies show a shift toward advanced materials that enhance durability. Innovations include lightweight composites and environmentally friendly polymers. These materials not only reduce production costs but improve performance metrics.

New design techniques are also significant. 3D printing technology allows for rapid prototyping. This method reduces material waste by up to 30%. Additionally, computer-aided design (CAD) streamlines the customization process, enabling manufacturers to meet specific industry needs. Industry reports indicate that plastic valve applications have surged by 25% in sectors like water treatment and pharmaceuticals.

However, these advancements come with challenges. The reliance on recent technologies may introduce quality control issues. Not all manufacturers can adapt quickly. Some struggle with the skill gap in utilizing advanced equipment. Industry experts emphasize the need for training and development to fully harness these innovations. The future of plastic valves depends on a well-prepared workforce.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.