Plastic ball valves are a crucial component in modern fluid control systems, widely recognized for their durability, corrosion resistance, and lightweight properties. According to a recent market research report by Global Market Insights, the plastic ball valve market is expected to exceed USD 2 billion by 2026, driven by increased demand across various industries, including water treatment, chemical processing, and food and beverage. These valves offer a reliable solution for controlling the flow of liquids and gases, ensuring efficiency and safety in numerous applications.

Industry expert Dr. Emily Harrison, a leading authority in valve technology, emphasizes the significance of plastic ball valves in sustainable engineering practices. She states, "The versatility and efficiency of plastic ball valves make them indispensable in applications that prioritize both performance and environmental responsibility." As industries strive for innovative solutions that align with sustainability goals, the use of plastic ball valves is expected to rise, showcasing their vital role in advancing efficient fluid management systems.

In this article, we will explore the types of plastic ball valves, their specific applications in various sectors, and the benefits they offer over traditional materials. Understanding these components is essential for engineers and decision-makers looking to enhance operational efficiency and reduce environmental impact.

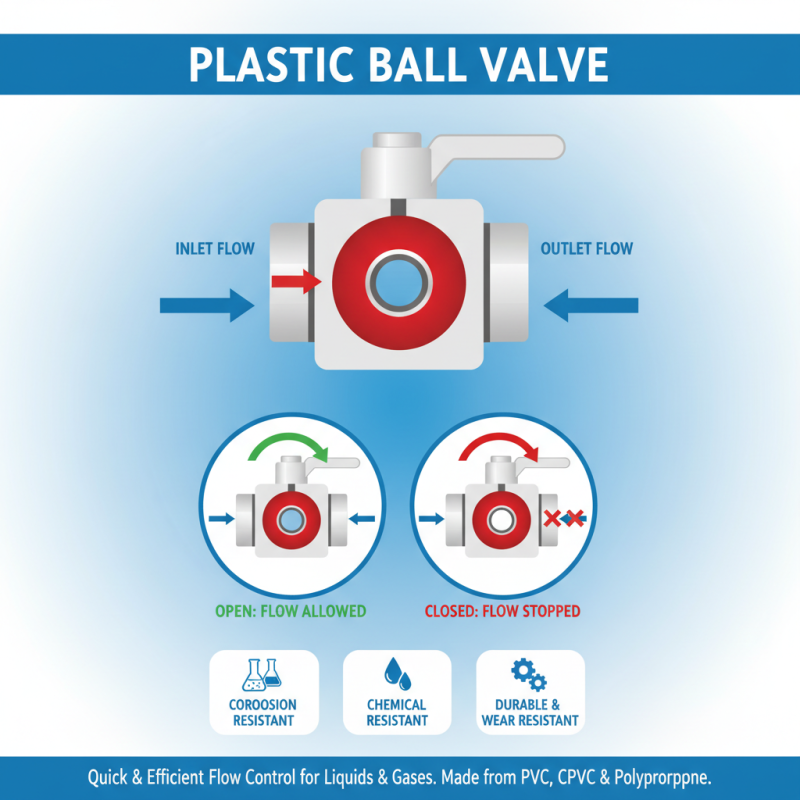

A plastic ball valve is a type of quarter-turn valve that utilizes a spherical disc, or ball, to control the flow of liquids or gases. The ball has a bore through it, and when the valve is turned—typically by using a handle—it either aligns or misaligns the bore with the flow direction, allowing for quick and efficient flow control. This type of valve is primarily made from materials like PVC, CPVC, or polypropylene, which offer excellent resistance to corrosion, chemical reactions, and wear, making them ideal for a variety of applications.

According to a report by MarketsandMarkets, the global plastic valve market is expected to reach USD 19.20 billion by 2025, with a compound annual growth rate (CAGR) of 5.7% from 2020 to 2025. Plastic ball valves are increasingly favored in industries such as water treatment, chemical processing, and food and beverage due to their lightweight nature and ease of installation. They also exhibit superior sealing capabilities, which can significantly enhance system efficiency and reduce maintenance costs. Additionally, a study by Grand View Research highlighted that the growing demand for sustainable and cost-effective solutions in fluid control applications is driving the adoption of plastic ball valves across various sectors.

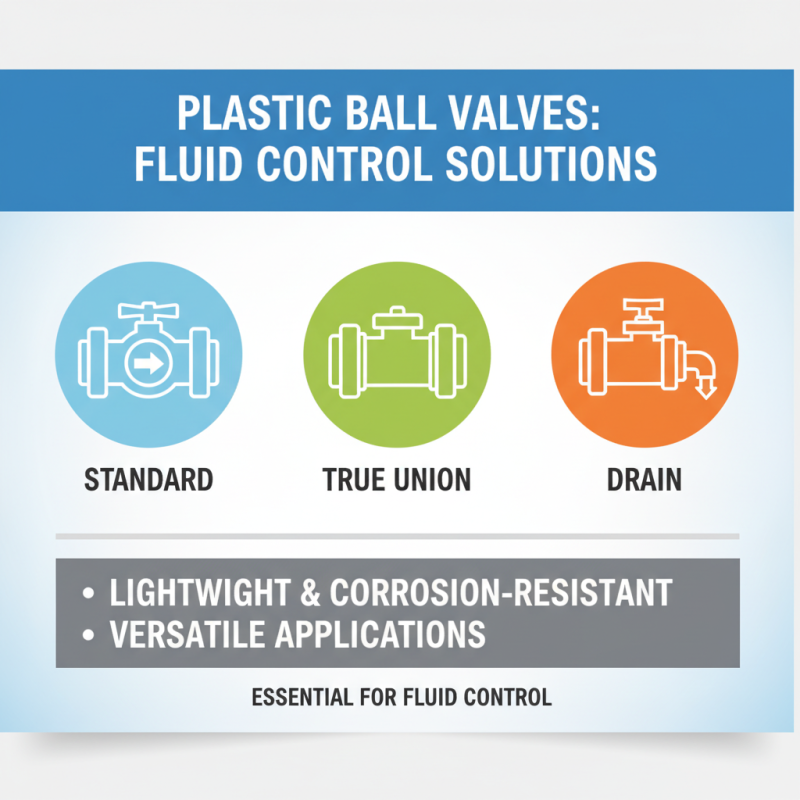

Plastic ball valves are an essential component in fluid control systems, widely utilized due to their lightweight, corrosion-resistant properties. There are several types of plastic ball valves, each designed to meet specific requirements depending on the application. The primary categories include standard plastic ball valves, true union ball valves, and drain ball valves.

Standard plastic ball valves are commonly used in simple on-off flow applications, where quick shut-off is necessary. True union ball valves offer the advantage of easily being disassembled from the pipeline, allowing for maintenance or replacement without cutting the pipes. Drain ball valves, on the other hand, are specifically designed for draining fluids from systems efficiently. These diverse options illustrate the versatility of plastic ball valves in various industries, including water treatment, agriculture, and chemical processing, where different functionalities and materials are essential to cater to specific fluid characteristics and operational demands.

Plastic ball valves are increasingly popular in various industries due to their key features and benefits. One of the most notable advantages is their lightweight nature. Unlike metal valves, plastic ball valves are easy to handle and install, which can significantly reduce labor costs. Additionally, they resist corrosion and chemical damage, making them ideal for applications involving aggressive fluids. This resilience extends the lifespan of the valve, leading to reduced maintenance and replacement expenses over time.

Another important feature is the design of the ball valve itself, which offers a straight-through flow path. This results in minimal pressure drop, ensuring efficient fluid flow. The simplicity of the design allows for quick operation, typically with a quarter turn to open or close the valve completely. This rapid response is crucial in applications requiring precise control over fluid flow and pressure regulation. Moreover, plastic ball valves are generally more versatile, being available in various sizes and configurations to suit different technical requirements, making them suitable for a wide range of applications, from water supply systems to chemical processing.

Plastic ball valves are versatile components employed in various industries due to their lightweight, corrosion resistance, and cost-effectiveness. In the chemical industry, these valves play a crucial role in managing the flow of aggressive fluids, providing a reliable solution for controlling chemical processes while minimizing the risk of leaks. Their ability to withstand harsh environments makes them ideal for applications in chemical batching, where precise flow regulation is essential for product quality and safety.

In the agricultural sector, plastic ball valves are commonly used in irrigation systems. They facilitate the management of water flow, allowing for efficient resource use and helping farmers tailor water delivery according to specific crop needs. This adaptability is vital for optimizing yields while conserving water, demonstrating the importance of plastic ball valves in promoting sustainable farming practices. Additionally, in food and beverage processing, these valves ensure hygienic operation and compliance with safety standards, safeguarding the quality of consumable products.

When it comes to plastic ball valves, proper maintenance and installation are crucial to ensure their longevity and optimal performance. During installation, it is important to follow the manufacturer's guidelines closely. This includes ensuring that the valve is installed in the correct orientation and that the piping is properly aligned to avoid stress on the valve body. Attention should also be paid to the torque specifications for the mounting bolts to prevent over-compression, which could lead to leaks or valve failure.

Regular maintenance of plastic ball valves involves periodic inspections and cleaning. Users should check for any signs of wear or damage, particularly in the seals and connections. Ensuring that the valve operates smoothly without any sticking is essential; if the valve is in a harsh environment, more frequent checks may be necessary. Routine flushing of the valve with compatible cleaning agents can help prevent buildup of deposits, maintaining optimal flow characteristics. It’s also advisable to replace seals and other components as needed to prolong the life of the valve and maintain system efficiency.

| Type of Plastic Ball Valve | Material | Application | Temperature Range (°C) | Pressure Rating (PSI) |

|---|---|---|---|---|

| Standard Plastic Ball Valve | PVC | Water, Chemicals | 0 to 60 | 150 |

| High-Density Polyethylene (HDPE) Ball Valve | HDPE | Agricultural, Waste Management | -30 to 70 | 100 |

| Corrosion-Resistant Ball Valve | PP (Polypropylene) | Acidic Solutions | 0 to 90 | 150 |

| Electric Plastic Ball Valve | PVC/CPVC | Automated Systems | -10 to 60 | 110 |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.