In the dynamic world of fluid control, the importance of utilizing the right components cannot be overstated. The comprehensive Cepex valves catalogue serves as an invaluable resource for engineers and procurement specialists seeking optimal performance in their applications. With an extensive range of products designed to meet diverse industry needs, this catalogue is not just a catalog; it is a guide to making informed decisions that can enhance operational efficiency and reliability.

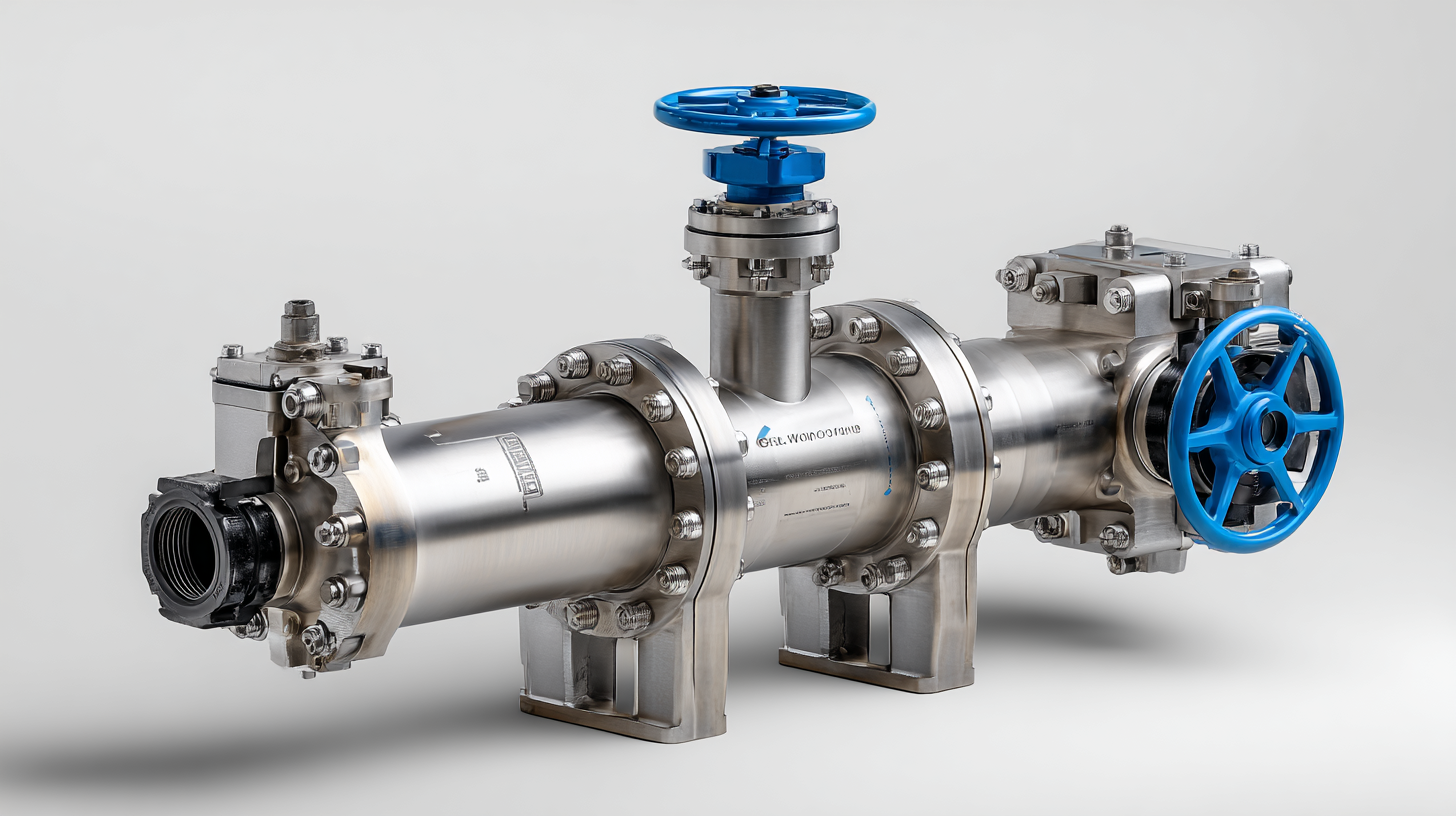

The 2025 Top 10 list highlights some of the most innovative and high-performing valves available in the market today, showcasing advanced features and exceptional materials that set them apart. By delving into the Cepex valves catalogue, users can explore state-of-the-art design principles and benefit from the latest technological advancements. Each entry in the catalogue is accompanied by detailed specifications and application recommendations, enabling users to find the perfect solution for their specific requirements.

The 2025 Top 10 list highlights some of the most innovative and high-performing valves available in the market today, showcasing advanced features and exceptional materials that set them apart. By delving into the Cepex valves catalogue, users can explore state-of-the-art design principles and benefit from the latest technological advancements. Each entry in the catalogue is accompanied by detailed specifications and application recommendations, enabling users to find the perfect solution for their specific requirements.

As we navigate through this guide, we will emphasize the significance of understanding the diverse offerings within the Cepex valves catalogue, ensuring that users are equipped to select the best options for superior performance and longevity. This exploration is not only a step towards optimizing fluid management systems but also a commitment to quality and reliability in engineering practices.

Understanding the key features and specifications of Cepex valves is essential for optimizing their performance in various applications. Cepex valves are known for their durability and versatility, with materials designed for resistance to corrosion and high pressures. A report by the Industrial Valve Market Research indicates that plastic valves, like those manufactured by Cepex, are gaining traction in sectors such as water treatment and chemical processing, where their lightweight nature and robust construction provide significant benefits.

One notable feature of Cepex valves is their ability to accommodate a wide range of operating temperatures and fluid types. According to data from the American Society of Mechanical Engineers (ASME), the use of thermoplastic materials in valve construction can lead to efficiency gains of up to 20% in certain applications. Additionally, Cepex valves often include advanced sealing mechanisms that ensure leak-proof operation, which is critical in industries where precision and reliability are paramount. Understanding these specifications not only aids in selecting the right valve but also assures optimal performance in demanding environments.

Navigating the 2025 Cepex Digital Catalogue is essential for anyone seeking optimal performance from their valve systems. This user-friendly guide is designed to simplify the process of finding the right valves for specific applications by employing an organized structure and advanced search functionality. As users explore the catalogue, they will notice various categories and subcategories that allow for easy filtering based on valve type, material, and specifications, ensuring a tailored selection for every project.

In addition to its intuitive navigation, the 2025 Cepex Digital Catalogue offers rich resources such as detailed product descriptions, technical datasheets, and multimedia tutorials. These features provide users with comprehensive knowledge about each valve's performance capabilities and installation guidelines. By leveraging these tools, engineers and procurement professionals can confidently make informed decisions that lead to enhanced efficiency and reliability in their operations. With this enhanced understanding, users can maximize the advantages of Cepex valves in their systems, ultimately driving superior outcomes in their projects.

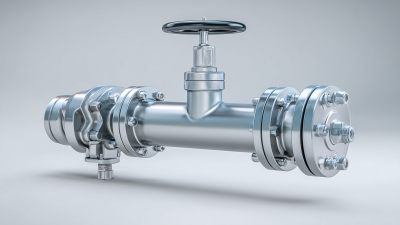

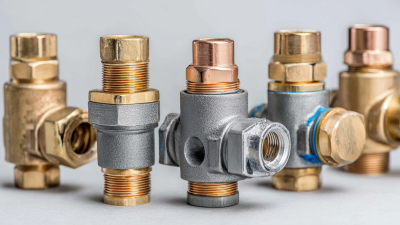

When selecting the right Cepex valve for your application needs, it is essential to consider the specific requirements of your system. Different applications require different valve types, such as ball valves for on/off control or check valves to prevent backflow. Assess the pressure, temperature, and fluid type involved in your process to ensure compatibility with the valve materials and design.

**Tips:** Before making a decision, consult the comprehensive Cepex valves catalogue to identify which models feature the specifications that align with your operational demands. Pay attention to factors like nominal size, pressure rating, and the presence of any specialized features. It may also be beneficial to reach out to Cepex's technical support for guidance tailored to unique challenges in your application.

Lastly, consider future maintenance and accessibility. Selecting a valve that not only meets your immediate needs but also allows for easy service can save time and resources in the long run. Always opt for products that offer durability and reliability to ensure optimal performance throughout their lifespan. Exploring the full Cepex valves catalogue will aid in making an informed choice that enhances operational efficiency.

When evaluating the performance of Cepex valves against competitors, it’s crucial to analyze key aspects such as durability, flow rates, and resistance to chemical corrosion. Cepex valves are renowned for their high performance, particularly in applications requiring stringent chemical handling. In contrast, some competitors may falter under extreme conditions, raising concerns about long-term reliability. A side-by-side operational comparison can shed light on these differences, highlighting Cepex's advanced materials and engineering that optimize their durability and ensure consistent performance over time.

Tips for effective comparison include examining the valves' specifications and customer reviews. Investigate materials used in valve construction—epoxy-coated and PVC options typically offer enhanced resistance against harsh environments. Additionally, consider testing samples under similar conditions to those they will face in actual operations. This hands-on evaluation can provide valuable insights into the performance capabilities of both Cepex and its competitors, allowing for a well-informed decision based on real-world applications.

When optimizing the use of Cepex valves, understanding their specifications and applications is crucial for maximizing efficiency. Research indicates that proper selection and functioning of valves can significantly enhance overall system performance and energy efficiency, as seen in various industrial applications. For instance, optimizing motor efficiency in industrial systems can lead to energy savings of up to 30%, highlighting the importance of effective component integration.

To ensure optimal usage of Cepex valves, here are some tips:

1. **Understand Flow Requirements**: Before selection, determine the specific flow rate and pressure requirements of your system. This knowledge will help avoid oversizing or undersizing the valves, which can lead to energy inefficiency.

2. **Regular Maintenance**: Implement a regular maintenance schedule to check for wear and tear. A well-maintained valve can operate at peak efficiency, much like the advancements in building technologies that have shown remarkable improvements in energy consumption.

3. **Leverage Automation**: Utilize automated systems for valve control to ensure they operate under optimal conditions consistently. Automation technologies have been shown to enhance resource use efficiency in various applications, similar to practices in advanced materials manufacturing.

By focusing on these strategies, users can significantly enhance the performance of Cepex valves, contributing to reduced operational costs and improved environmental sustainability.

| Valve Type | Material | Operating Pressure (bar) | Temperature Range (°C) | Connection Type | Application |

|---|---|---|---|---|---|

| Ball Valve | PVC | 10 | 0 to 60 | Threaded | Water Treatment |

| Gate Valve | PP | 16 | -10 to 80 | Flanged | Industrial Applications |

| Butterfly Valve | Stainless Steel | 20 | -20 to 100 | Welded | Chemical Processing |

| Check Valve | Bronze | 25 | 0 to 80 | Threaded | Oil and Gas |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.