When it comes to constructing or repairing projects that require the use of plumbing or piping systems, choosing the right plastic fittings is crucial. The diverse range of materials, sizes, and designs available in the market can be overwhelming. However, making informed decisions is essential to ensure the longevity and effectiveness of your project. In this guide, we will explore ten essential tips that will help you navigate the complexities of selecting the best plastic fittings tailored to your specific needs.

Understanding the characteristics and applications of different types of plastic fittings can significantly impact the performance of your project. Whether you are working on a DIY home improvement task or a professional plumbing job, choosing the correct fittings can prevent potential issues down the line. From compatibility with various types of pipes to considerations regarding pressure ratings and temperature tolerances, our tips will equip you with the knowledge necessary to make optimal choices. Join us as we unravel the secrets to finding the best plastic fittings that will contribute to the success of your projects.

When selecting plastic fittings for various projects, understanding the different types available and their specific applications is crucial. Plastic fittings are typically made from materials such as PVC, CPVC, and polyethylene, each offering unique characteristics that cater to distinct needs. For instance, PVC fittings are highly versatile and commonly used in plumbing applications due to their durability and resistance to corrosion, making them suitable for both residential and commercial plumbing systems.

Another important type is CPVC, which can withstand higher temperatures than standard PVC, making it ideal for hot water applications. On the other hand, polyethylene fittings are often utilized in outdoor and industrial applications because of their excellent resistance to UV radiation and impact. Choosing the right type of fitting not only ensures the longevity of your project but also enhances its efficiency and reliability. By assessing the environmental conditions and specific requirements of your project, you can make an informed decision that aligns with your needs.

When selecting plastic fittings for your projects, several key factors should guide your decision-making process. First and foremost, consider the specific application and environment in which the fittings will be used. Different materials offer varying levels of resistance to chemicals, temperature fluctuations, and UV exposure. For example, if your project involves plumbing in an outdoor setting, UV-resistant PVC fittings may be a necessity to ensure longevity.

Another critical factor is the compatibility of the fittings with the pipes or components you are using. It's important to select fittings that match the size, threading, and material of your existing system. Mismatched connections can lead to leaks or failures over time. Additionally, think about ease of installation; some fittings are designed for quick and simple assembly, which can save valuable time and labor costs during your project. By carefully considering these factors, you can ensure that you choose the right plastic fittings to achieve a successful and durable outcome.

| Tip | Description | Material Types | Common Applications |

|---|---|---|---|

| 1. Determine the Application | Identify the specific use case to select suitable fittings. | PVC, CPVC, PVDF | Water supply, chemical handling |

| 2. Consider Pressure Ratings | Ensure fittings can handle the required pressure levels. | ABS, Nylon | Pneumatic systems, appliances |

| 3. Evaluate Temperature Resistance | Select fittings that can withstand the temperatures of use. | PP, HDPE | Hot water systems, food processing |

| 4. Assess Chemical Compatibility | Ensure selected materials are compatible with chemicals being used. | PVDF, Teflon | Laboratory use, industrial operations |

| 5. Factor in Fitting Sizes | Ensure fitting sizes match with piping dimensions. | Various sizes available | Plumbing, irrigation |

| 6. Choose Reliable Brands | Opt for known manufacturers to ensure quality. | N/A | General use |

| 7. Review Installation Requirements | Understand if specialized tools are needed for installation. | N/A | Varied applications |

| 8. Calculate Cost vs. Performance | Evaluate if the cost aligns with expected performance. | N/A | All types of systems |

| 9. Investigate Maintenance Needs | Check if fittings require regular maintenance. | N/A | System longevity |

| 10. Ensure Compliance with Standards | Verify that fittings meet local building codes and standards. | N/A | Safety and legality |

When selecting plastic fittings for your projects, evaluating the durability and performance of various plastic materials is crucial. Different types of plastics, such as PVC, CPVC, and Polyethylene, each offer unique strengths and weaknesses.

For instance, PVC is highly resistant to environmental degradation and chemicals, making it ideal for plumbing and drainage applications. In contrast, Polyethylene is known for its superior impact resistance and flexibility, which can be advantageous in applications requiring movement or bending.

In addition to material choice, it’s important to consider the specific conditions your fittings will encounter. High-temperature environments may require fittings made from CPVC, as it maintains structural integrity better than standard PVC. Always check the manufacturer's specifications regarding pressure ratings and temperature tolerances to ensure that the fittings will perform as expected in your application.

Finally, remember to assess compatibility with other materials in your project. Ensure that the selected plastic fittings can seamlessly integrate with existing pipes or fixtures to avoid issues such as leaks or weakened connections over time. Taking these factors into account will lead to more successful and enduring installations.

When selecting plastic fittings for your projects, ensuring compatibility with other components is crucial for optimal performance and longevity. First, consider the chemical properties of both the fittings and the materials they will connect with. For instance, certain plastics are resistant to specific chemicals while others may degrade or react negatively. It is essential to match the fittings with compatible materials to avoid leaks or failures over time, particularly in plumbing, irrigation, or chemical processing applications.

Another aspect to consider is the temperature and pressure ratings of the plastic fittings. Different plastic materials can handle varying levels of heat and pressure; selecting fittings that can withstand the operational conditions of your project is vital. Additionally, look for certifications or standards that indicate the fittings' suitability for the intended application. Taking the time to assess these factors will contribute to the overall efficiency and reliability of your project, ultimately saving time and costs related to potential repairs or replacements.

Choosing the right plastic fittings for your projects can significantly impact efficiency, durability, and overall success. One common mistake that many professionals make is overlooking the importance of material compatibility. According to a study by the Plastics Industry Association, approximately 30% of project failures can be traced back to improper material selection. Different plastic types such as PVC, CPVC, and polyethylene have varying resistance to chemicals and temperature changes, which can lead to leaks or system failures if not matched correctly with their intended use.

Another frequent pitfall is failing to consider the fittings' pressure rating. The American Society for Testing and Materials (ASTM) reports that nearly 20% of plumbing issues arise from underestimating the pressure requirements of a system. It is crucial to consult pressure ratings and ensure that the fittings can withstand the specific demands of your project environment. Additionally, suppliers often provide performance data that can guide you in selecting fittings that meet regulatory standards and performance benchmarks, minimizing the risk of costly errors down the line.

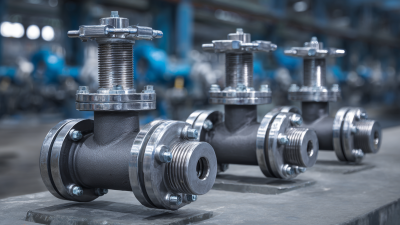

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.