When embarking on any plumbing or construction project, the selection of the right materials is crucial to ensure long-term durability and functionality. Among these materials, PVC fittings stand out due to their strength, resistance to corrosion, and cost-effectiveness. Recent industry reports indicate that the global PVC fittings market is expected to witness significant growth, driven by the increasing demand in sectors such as construction and irrigation. The PVC fittings segment is expected to account for a substantial share, indicating their critical role in contemporary applications.

Choosing the right PVC fittings for your project is not just an exercise in material selection; it is a strategic decision that impacts performance and maintenance. According to a survey by the Plastics Pipe Institute, approximately 70% of plumbing professionals report that improperly selected fittings lead to costly repairs and project delays. This highlights the importance of understanding the various types of PVC fittings available, their specifications, and their suitability for specific applications.

In this guide, we will delve into the ten essential tips that will help you navigate the selection process and ensure that your projects benefit from the optimal performance of PVC fittings.

When embarking on a project that requires PVC fittings, it’s crucial to identify the right type of fittings tailored to your specific needs. Different projects may demand varying specifications; for instance, plumbing systems generally require standard PVC fittings, while more specialized applications like industrial or agricultural projects may necessitate fittings with enhanced chemical resistance or higher pressure ratings. According to the Plastics Industry Association, the growth of the PVC fittings market is projected to reach over $7 billion by 2025, driven significantly by advancements in manufacturing technology and increased demand across various sectors.

Choosing the right PVC fittings involves assessing factors such as pressure requirements, the environment where the installation will occur, and the compatibility with the existing systems. The American Society for Testing and Materials (ASTM) suggests using Schedule 40 or Schedule 80 fittings for standard applications, while Schedule 80 is recommended for higher pressure systems due to its thicker walls. Additionally, consider the fittings' certifications, which can impact safety and compliance; for example, fittings certified under NSF/ANSI standards ensure suitability for potable water systems. This careful evaluation can lead to more effective and durable installations, ultimately enhancing the success of your project.

When selecting PVC fittings for your projects, understanding the importance of size and compatibility cannot be overstated. A notable report by the Plastics Industry Association indicates that improper sizing accounts for over 20% of installation failures in plumbing and drainage systems. This statistic highlights the critical need for precise measurements when choosing fittings. To ensure compatibility, it is essential to consider not only the nominal pipe size but also the specific requirements of your project's design and function.

In addition to size, the compatibility of different types of PVC materials plays a significant role in long-term performance. The American Society for Testing and Materials (ASTM) sets rigorous standards that dictate which fittings work best with schedule 40 or schedule 80 pipes. For instance, mismatches in pressure ratings can lead to system failures, costing both time and resources. Therefore, utilizing compatible fittings as per ASTM guidelines is crucial for minimizing risks and ensuring durability in PVC installation projects. Key industry insights suggest that correctly matched fittings can extend the lifespan of a system by up to 30%, making informed choices vital for any successful PVC project.

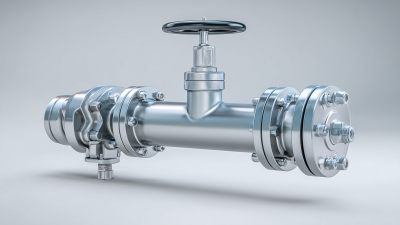

When selecting PVC fittings for various projects, it's crucial to evaluate the different material grades available and their respective applications. PVC fittings are manufactured from different grades of polyvinyl chloride, such as schedule 40 and schedule 80, each offering distinct characteristics suitable for specific environments.

Schedule 40, for instance, is commonly used in residential plumbing systems due to its lighter weight and lower pressure ratings, while schedule 80 is preferred in industrial applications where higher pressure and durability are essential.

Schedule 40, for instance, is commonly used in residential plumbing systems due to its lighter weight and lower pressure ratings, while schedule 80 is preferred in industrial applications where higher pressure and durability are essential.

Understanding the specific requirements of your project, including factors like temperature, pressure, and chemical exposure, will guide your choice in material grade. For instance, higher-grade PVC fittings can withstand more significant stress and exposure to harsh chemicals, making them ideal for chemical processing or underground installations. Additionally, considering the long-term reliability and performance of the fittings can help prevent future issues, ensuring the success of your project.

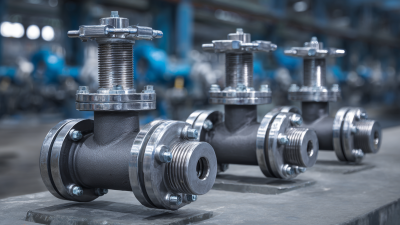

When it comes to selecting PVC fittings for your projects, understanding the differences between solvent welded and mechanical joint options is crucial. Solvent welded joints are created by chemically bonding the fittings together, which results in robust, leak-free connections. According to a report from the Plastic Pipe and Fittings Association (PPFA), solvent welding can yield a joint strength up to 2000 psi, making it an ideal choice for high-pressure applications. This method is widely favored in situations where durability and longevity are essential, such as in industrial and municipal water systems.

On the other hand, mechanical joint fittings utilize a combination of gaskets and bolts or clamps to create a secure connection. They are easier to install and remove, which can be an advantage in maintenance-heavy settings. A study by the American Society of Civil Engineers (ASCE) highlights that mechanical joints can reduce assembly time by up to 30%, making them a cost-effective solution for projects that require frequent adjustments or repairs. Ultimately, the decision between solvent welded and mechanical joints should be guided by the specific requirements of your project, including pressure ratings, installation conditions, and ease of maintenance.

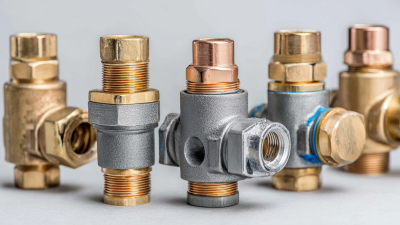

When selecting PVC fittings for your projects, it's vital to recognize the key features that indicate quality. One of the most critical aspects is the fitting's material composition. High-quality PVC fittings typically contain a higher percentage of virgin polyvinyl chloride, enhancing durability and resistance to environmental factors. According to a recent industry report by the Plastic Pipe and Fittings Association (PPFA), fittings made from 100% virgin PVC demonstrate a significantly longer lifespan than those made from recycled materials, which can lead to increased maintenance costs over time.

Another important feature to consider is the connection type. Options like solvent weld, threaded, and slip-joint connections each have their specific advantages. For example, solvent weld connections create a permanent bond that can withstand higher pressures, making them ideal for high-stakes applications like plumbing. A 2022 survey revealed that improper connections were responsible for 30% of plumbing failures, highlighting the importance of choosing the appropriate connection type.

Additionally, certification and standards play a crucial role in assessing the quality of PVC fittings. Look for fittings that meet American National Standards Institute (ANSI) or ASTM (American Society for Testing and Materials) standards, as these certifications ensure that the products adhere to rigorous safety and quality requirements. Overall, focusing on these key features can help you make informed decisions and ensure the success of your projects.

| Tip | Description | Key Feature | Importance |

|---|---|---|---|

| 1. Material Quality | Choose fittings made from high-quality PVC to ensure durability. | High Impact Resistance | Prevents cracking and failure. |

| 2. Size Compatibility | Ensure the fittings match the pipe sizes you're working with. | Correct Dimensions | Ensures a proper seal and fitting. |

| 3. Pressure Ratings | Check the pressure ratings to match your project needs. | Rated for Specific Pressure | Prevents leaks under pressure. |

| 4. Ease of Installation | Look for fittings that are easy to assemble and disassemble. | User-Friendly Design | Saves time and effort during installation. |

| 5. Certification and Standards | Select fittings that meet industry standards. | Compliance with Norms | Provides assurance of quality and safety. |

| 6. Chemical Resistance | Consider the chemical exposure of your application. | Resistant to Corrosion | Extends the lifespan of fittings. |

| 7. Temperature Ratings | Select fittings that can withstand the temperatures of your application. | Thermal Stability | Prevents warping or melting. |

| 8. Color and Appearance | Choose a fitting color that is suitable for your project. | Aesthetic Appeal | Enhances the overall look of your system. |

| 9. Warranty and Support | Check for manufacturers that offer warranties and support. | Customer Protection | Provides peace of mind for product investment. |

| 10. Cost vs. Quality | Evaluate cost against quality—cheaper isn’t always better. | Value for Money | Ensures long-term satisfaction. |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.