Understanding the different types of valves is crucial for various industries. According to John Smith, a valve technology expert, "Valves are the unsung heroes of fluid control." His insight highlights the importance of these devices. Valves regulate flow, pressure, and direction in systems, ensuring efficiency and safety.

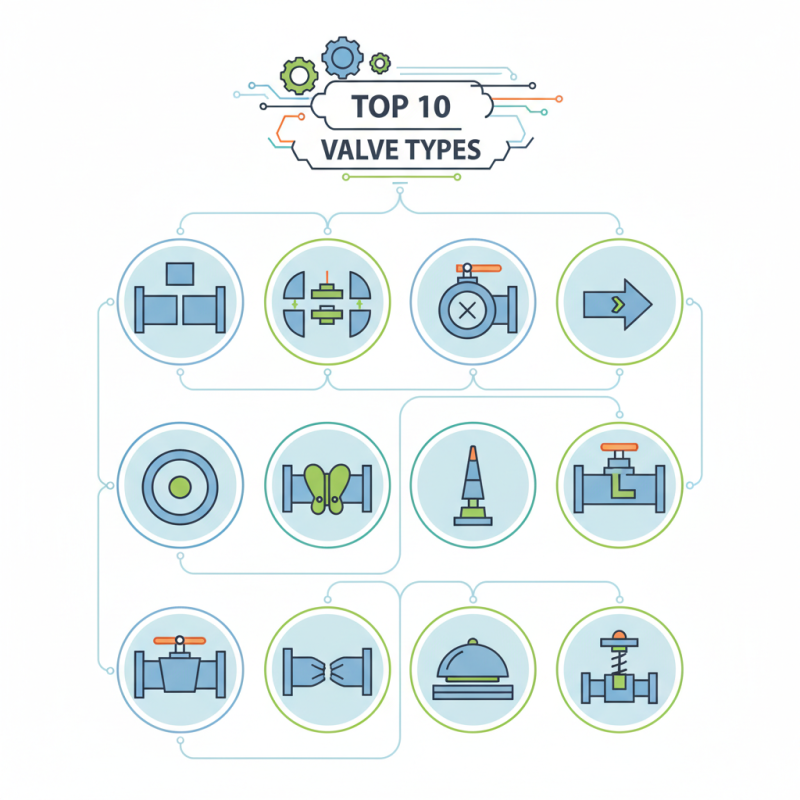

There is a myriad of different types of valves, each designed for specific functions. For example, gate valves allow or block flow with a simple lift. Conversely, check valves prevent backflow and protect systems from damage. Ball valves, with their quick operation, are popular in many applications. Each type serves a unique purpose, often leading to confusion in selection.

Choosing the right valve isn't always straightforward. Many factors come into play, such as material, pressure rating, and intended use. It's essential to consider these details to ensure optimal performance. Understanding these different types of valves can be a daunting task. Yet, it's a vital one that can save time and resources in the long run.

Valves are crucial components in various industries, controlling fluid flow and pressure. Understanding different types helps in selecting the right one for specific applications. According to a recent industry report, the global valve market is expected to grow at a CAGR of 5.8% from 2022 to 2028. This growth highlights the importance of efficient valve systems in modern operations.

Each valve type serves distinct purposes. Gate valves allow fluid to flow in a straight line, which is ideal for on/off control. Ball valves offer quick shut-off and low resistance to flow. Butterfly valves are perfect for throttling and have a lightweight design. Check valves prevent backflow, ensuring safety in systems. Each type has specific applications, from water treatment to oil and gas.

Tip: Always consider the medium being controlled. The choice of valve material is critical. Some mediums can corrode or damage specific materials.

Another essential factor is pressure rating. It determines how much pressure a valve can handle. A mismatch can lead to failures. Regular maintenance is vital for this reason. Check seals and joints regularly to avoid leaks.

Tip: Thoughtful selection based on application specifics can save costs and improve efficiency. Consider both short-term and long-term needs in your decision-making process.

Ball valves are critical components in various industries. Their design allows for quick shut-off and easy control. These valves use a spherical disc to manage flow. When the ball is aligned with the flow, it stays open. When rotated, it seals against the valve seat. This mechanism provides excellent sealing properties.

One key advantage of ball valves is their durability. They can withstand high pressure and temperature. Their simple design allows for minimal maintenance. However, not all ball valves are created equal. Some might develop leaks over time. It's essential to choose the right type for your application. In pipelines, for instance, they are common for oil and gas transport.

Ball valves find use in many scenarios. They are often found in water supply systems. They can control water flow efficiently. In the chemical industry, they handle various fluids. When selecting a ball valve, consider the material and environment. Misjudgments in selection may lead to operational issues. Understanding your specific needs is crucial for success.

Gate valves are essential components in various industries. They control the flow of liquids and gases. Understanding their performance metrics is crucial for effective operations. These valves typically operate by lifting a gate out of the path, allowing fluid to flow smoothly. The design allows for minimal pressure drop, which is beneficial in many applications.

Performance metrics for gate valves include pressure ratings and temperature tolerances. They are measured in terms of how much pressure the valve can handle and at what temperature it operates efficiently. This information helps in selecting the right valve for specific conditions. However, it's important to remember that some valves may perform well in one scenario but not in another. Testing and validation are necessary to ensure reliability.

Industry standards are vital for gate valves. These standards guide manufacturing and testing processes. Variations in materials and designs can lead to inconsistencies. Vigilance is needed to maintain quality and compliance. Understanding the full scope of these metrics and standards can prevent costly mistakes in the long run. It can be a challenging journey, requiring constant reflection and adaptation.

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Application Area |

|---|---|---|---|---|

| Gate Valve | Cast Iron | 150 | -20 to 200 | Water Supply |

| Globe Valve | Stainless Steel | 300 | -4 to 400 | Oil & Gas |

| Ball Valve | Brass | 600 | -20 to 180 | Chemical Processing |

| Butterfly Valve | PVC | 150 | 0 to 130 | Water Treatment |

| Check Valve | Aluminum | 150 | -20 to 180 | Fire Protection |

| Pressure Relief Valve | Carbon Steel | 2000 | -40 to 150 | Steam Systems |

| Solenoid Valve | Nylon | 150 | -10 to 140 | Irrigation Systems |

| Diaphragm Valve | EPDM | 100 | 0 to 180 | Pharmaceuticals |

| Pinch Valve | Natural Rubber | 50 | -10 to 150 | Wastewater Treatment |

| Swing Check Valve | Copper | 300 | -20 to 200 | Hydraulic Systems |

Check valves play a crucial role in fluid control systems. They ensure that fluids flow in one direction only. This functionality prevents backflow, which can lead to system failures. Imagine a water pipeline: without check valves, water could flow backward, causing damage. These devices are essential in applications ranging from residential plumbing to industrial processes.

When selecting check valves, consider the maximum pressure and temperature ratings. Compatibility with the fluid is also vital. Some valves work better with specific materials. Regular maintenance is key to ensuring their effectiveness. Check for leaks or wear. Addressing these issues can prevent larger problems down the line.

Tips: Always install check valves in a vertical position for optimal performance. Use a strainer upstream to avoid debris clogging. Proper sizing is important; too small can restrict flow, too large may not close properly. Investing time in proper selection and installation pays off in reliability.

This bar chart illustrates the importance ratings of different types of valves commonly used in fluid control systems. The check valve stands out with a top rating of 10, emphasizing its critical role in preventing backflow in piping systems.

Butterfly valves are essential for regulating fluid flow in various industries. Their design is simple yet effective. A disk is mounted on a rotating shaft, allowing for quick opening and closing. This mechanism reduces resistance, enhancing flow efficiency. In many applications, they are favored for their compact size and lightweight nature.

Design variations of butterfly valves cater to different needs. Some feature resilient seat designs for better sealing. Others may use metal seats for higher temperature applications. Each variation aims to achieve specific operational efficiencies. However, these modifications can introduce complexities. Maintenance might become more frequent if the wrong type is chosen for the application.

Efficiency is a key factor in using butterfly valves. Proper selection can lead to significant energy savings. However, mismatched designs could cause flow issues. Users should test different types under actual conditions. Feedback from these trials is crucial. This process can reveal potential areas for improvement. It’s important to weigh the pros and cons carefully.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.