Choosing the right actuated valves is pivotal for optimizing fluid control systems. In recent studies, the global actuated valves market is expected to reach $7 billion by 2025, growing at a CAGR of 6%. This growth highlights the increasing demand in various industries, such as oil and gas, water management, and manufacturing.

Actuated valves offer precise control over the flow of liquids and gases. They enhance automation, improve efficiency, and reduce manual labor. Selecting the right type can be challenging. Each application has unique requirements. It’s crucial to understand factors like pressure ratings, material compatibility, and actuation type. Misunderstanding these aspects can lead to inefficiencies.

In some cases, end-users overlook the long-term costs associated with their choices. A cheaper option may not always yield the best performance. It’s important to reflect on reliability, maintenance, and lifecycle costs. Making informed decisions on actuated valves will ultimately result in better operational outcomes and enhanced system efficiency.

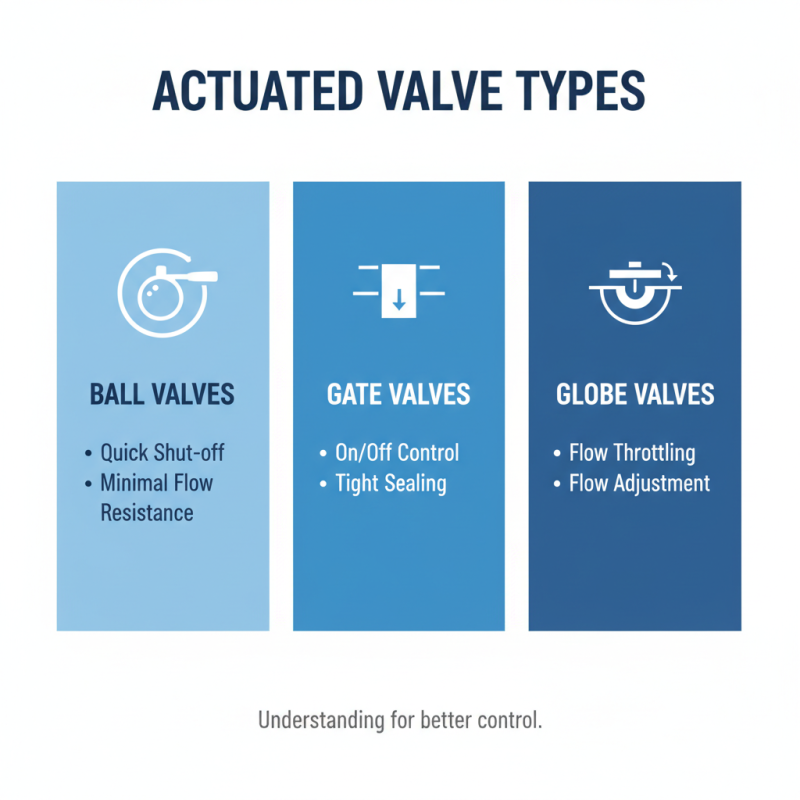

When choosing actuated valves, understanding their types is crucial. There are several main categories: ball valves, gate valves, and globe valves. Each type has unique functions. A ball valve is often used for quick shut-off. Its design allows for minimal flow resistance. Gate valves, in contrast, are better for on-off control. They provide tight sealing but are less effective for flow regulation. Globe valves facilitate better throttling, making them ideal for flow adjustment.

Electric actuated valves use an electric motor to operate. They offer precision and control. Pneumatic actuated valves, driven by air pressure, respond rapidly but require a compressed air source. Hydraulic actuated valves use fluid pressure and are suited for heavy-duty applications. Selecting the right actuator matters greatly. It influences performance and efficiency. Sometimes, users might overlook specific requirements. Factors like pressure rating and temperature tolerance are essential to consider. The space available for installation can be limiting and might even necessitate custom solutions.

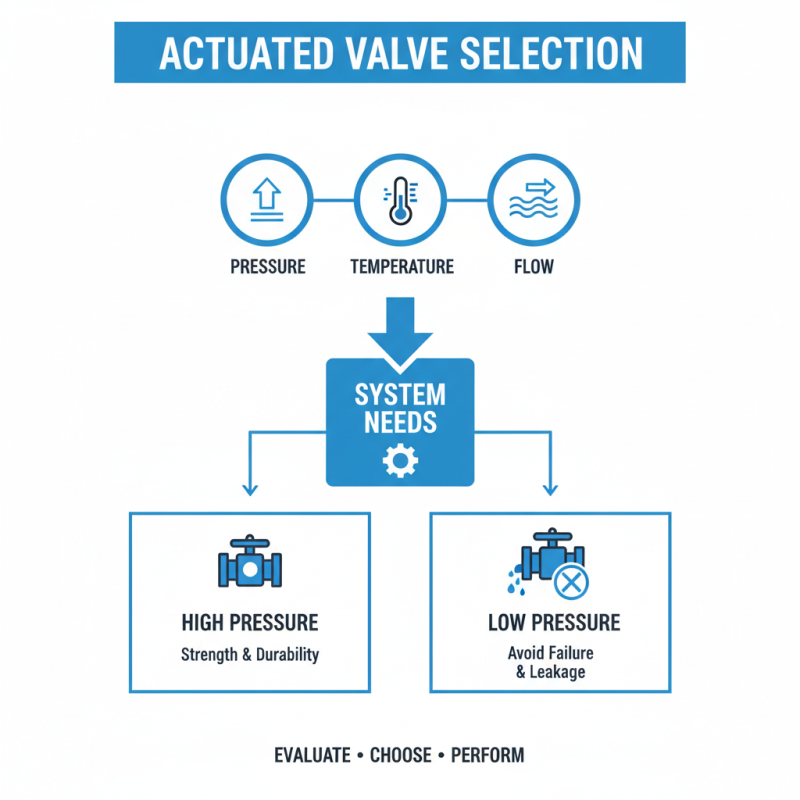

Selecting the right actuated valves requires a deep understanding of your system's needs. Evaluating pressure, temperature, and flow is crucial. Each parameter influences the valve's effectiveness. For example, high-pressure systems demand valves that can withstand those conditions. Valves may fail if pressure ratings are ignored. A low-pressure rating could lead to leakage or damage.

Temperature also plays a vital role. Different materials respond uniquely to heat. Certain valves may work well in moderate temperatures but falter in extremes. Understanding the operational temperature range helps in making informed choices. Misjudging it could lead to premature wear or failure.

Flow considerations cannot be overlooked. The design of the valve affects how fluid travels through it. An inappropriate valve size may restrict flow or create turbulence. This misalignment can hinder system performance. Balancing these elements thoughtfully is essential. Ignoring even one can lead to significant inefficiencies in your system.

When selecting the right actuator type for your valves, consider the application.

Electric actuators are often praised for their precision. They excel in environments where accurate control is essential.

With a wide range of sizes, they can fit various valve dimensions. Their ease of integration with control systems is another plus.

However, they may struggle in extreme temperatures.

Pneumatic actuators are powerful. They respond quickly, making them ideal for applications needing rapid operation.

They utilize compressed air, which allows for robust performance. But you should be cautious about their dependency on air supply.

A sudden loss of air may cause operational issues.

Hydraulic actuators offer significant force.

They work well in heavy-duty applications. However, they can be complex to maintain. The hydraulic fluid needs regular checks.

Each actuator type has its pros and cons, making careful consideration vital. Balancing efficiency and operational costs can provide insights.

When selecting actuated valves, material compatibility is crucial. Different fluids and environments can react negatively with certain materials. Choosing the wrong material can lead to corrosion, leaks, or even valve failure. It's vital to identify the operational conditions of your system. Are the fluids corrosive or abrasive?

Beyond liquid compatibility, consider temperature and pressure ranges. High temperatures can degrade some materials faster than expected. Under pressure, certain metals might not perform as needed. Often, people overlook these aspects, which can lead to costly repairs. Research is essential, but clarity in specifications is equally important.

Consulting with experts can help. However, not all recommendations fit every situation. A valve material might work in one application but fail in another. Conducting tests, if possible, will yield better results. Finding a balance between cost and longevity is important. Don't rush this decision; the right choice is about performance and reliability over time.

When budgeting for actuated valves, it's crucial to consider both initial costs and long-term expenses. Quality matters, but so does affordability. You may find cheaper options, but they might lack durability. Evaluating lifecycle costs helps you avoid unexpected expenses later.

Tips: Always calculate maintenance costs. A valve that saves money upfront may have higher operational costs. Research available materials for better durability. Stainless steel may have a higher purchase price but lasts longer.

Don't forget installation fees. These costs can add up quickly. Sometimes, a slightly more expensive valve is easier and cheaper to install. Check compatibility with your current systems. Misfits can lead to additional expenses and time lost.

Think about performance. A valve that works brilliantly may not be budget-friendly. If it breaks down, repairs can exceed initial savings. Ask questions to clarify warranties and longevity. A cheap valve could require more replacements, increasing overall costs.

The chart above presents the average costs associated with different types of actuated valves, which is a crucial factor to consider when budgeting for your needs. Electric valves tend to be more expensive, while pneumatic options are more budget-friendly. Understanding these costs will help you make informed decisions based on your project requirements.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.