Selecting the right valves manufacturers for your industrial needs is a critical decision that can significantly impact your operations. Valves play a crucial role in controlling the flow of liquids and gases in various systems, making it essential to partner with reliable manufacturers who offer quality products tailored to your industry requirements. The choice of valves can affect not only the efficiency of your processes but also overall safety and compliance with standards.

When evaluating potential valves manufacturers, it is important to consider several key factors, such as their production capabilities, quality assurance processes, and their track record in delivering products that meet or exceed industry standards. Additionally, understanding the specific needs of your application—whether it involves high pressure, extreme temperatures, or corrosive substances—is fundamental in ensuring that the valves you select will perform optimally in your environment. By thoroughly vetting manufacturers and aligning their strengths with your operational demands, you can ensure that your industrial processes run smoothly and efficiently.

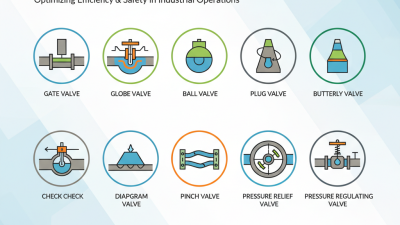

When selecting the right valves for industrial applications, it's essential to understand the various types of valves and their specific functions. Each type of valve serves a unique purpose within a system, and recognizing these distinctions can significantly impact efficiency and safety. The most common types include gate valves, globe valves, ball valves, and check valves. Gate valves are primarily used for on/off control, allowing fluid to flow freely when open, while globe valves provide better flow regulation, making them suitable for throttling applications.

In addition, ball valves are favored for their quick operation and low pressure drop, making them ideal for shut-off applications. They are often used in situations where a fast and reliable seal is necessary. Conversely, check valves are designed to prevent backflow, ensuring that the flow of fluid proceeds in a single direction. Each type of valve has specific materials and design features tailored to withstand high pressures, temperatures, and aggressive media, which is a critical consideration in industrial environments. Understanding these types helps ensure that the selected valves not only meet operational requirements but also enhance the overall performance of the industrial processes.

When selecting valve manufacturers for industrial applications, it is essential to consider several key factors that can significantly impact both performance and cost-efficiency. One primary consideration is the manufacturer’s experience and expertise in the specific industry. According to a report by the Global Valve Market Insights, companies with over 15 years in the industry tend to have a deeper understanding of complex requirements and regulatory standards, reducing the likelihood of costly errors during the supply chain process.

Another important factor is the range of products offered by the manufacturer. A comprehensive product line not only ensures that you find the suitable valve type for your requirements but also facilitates future needs as your operations expand. The 2022 Industrial Valve Market Analysis indicated that manufacturers offering a diverse array of valves, including but not limited to ball valves, butterfly valves, and check valves, are better equipped to deal with the evolving demands of various industrial sectors. Additionally, assessing the manufacturer's commitment to quality and compliance certifications, such as ISO 9001, can provide insights into their operational standards and product reliability.

Lastly, customer support and after-sales service are critical elements that should not be overlooked. A manufacturer that offers robust support, including technical assistance and warranty services, can be a vital partner in troubleshooting and maintaining optimal valve function, which is crucial in preventing costly downtime. According to recent surveys, companies that prioritize strong customer service and responsive communication report up to 30% higher satisfaction rates, indicating the importance of this factor in selecting a valve manufacturer.

When selecting a valve manufacturer for your industrial needs, evaluating the quality standards and certifications is crucial. A manufacturer’s adherence to international quality standards such as ISO 9001:2015, which focuses on a quality management system, is a significant indicator of their operational quality and reliability. According to the International Organization for Standardization, nearly 1.5 million organizations are certified to ISO 9001 across the globe, demonstrating a widespread commitment to quality assurance that consumers should seek in their suppliers.

Additionally, compliance with industry-specific standards such as API 6D for pipeline valves or ASME for pressure vessels can further assure manufacturers’ capabilities. Reports from the Valve Manufacturers Association indicate that valves play a crucial role in up to 70% of industrial applications, emphasizing the importance of selecting manufacturers who adhere to these stringent criteria. Furthermore, certifications such as CE marking, which denotes conformity with health, safety, and environmental protection standards for products sold within the European Economic Area, can increase marketability and customer trust. Therefore, a thorough examination of quality standards and certifications can prevent costly failures and ensure the longevity and effectiveness of industrial operations.

When selecting valve manufacturers for industrial applications, it’s crucial to consider their experience and reputation within the industry. An experienced manufacturer often has a deep understanding of the technical requirements and challenges that various applications pose. Their longevity in the market typically reflects a commitment to quality and innovation. This extensive background can lead to better product reliability and efficiency, as seasoned manufacturers are more likely to implement the latest technologies and industry best practices in their production processes.

Furthermore, assessing a manufacturer’s reputation is equally important. A good standing in the industry can indicate not only product quality but also customer service and support after the sale. Reviews and testimonials from previous clients can provide valuable insights into their experiences, highlighting aspects such as delivery times, responsiveness, and the ability to meet specific project requirements.

Engaging with industry forums or trade associations can also reveal how peers view a particular manufacturer’s reliability and performance in various contexts, helping you make an informed decision that aligns with your industrial needs.

When selecting valve manufacturers for your industrial needs, it’s crucial to closely analyze pricing and support options. Pricing structures can vary significantly among suppliers, so understanding the cost implications is essential for budget management. Look for manufacturers who provide transparent pricing models, allowing you to compare the costs of different valve types and accompanying services. This transparency not only facilitates better decision-making but also helps in identifying potential hidden fees or long-term costs associated with maintenance and operation.

In addition to pricing, consider the quality of customer support offered by valve suppliers. A reliable manufacturer should provide comprehensive services, including technical support, installation guidance, and after-sales service. Assessing their responsiveness and expertise can often indicate how well they will assist you throughout the product lifecycle. A supplier that offers robust support can mitigate risks, ensure optimal performance of the valves, and ultimately contribute to your operational efficiency. By evaluating both pricing and support options, you can make a more informed decision that aligns with your industrial requirements.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.