When choosing the right plastic ball valves for your project, it’s essential to understand their unique characteristics. As industry expert, Dr. Emily Carter, once said, "The right plastic ball valve can make or break your system’s efficiency." Understanding the specifications and applications of these valves can greatly impact your project’s outcome.

Plastic ball valves are known for their corrosion resistance and lightweight features. They are commonly used in various industries, such as chemical processing and water treatment. However, selecting the wrong valve can lead to leaks or inefficiencies. It’s crucial to consider factors like pressure ratings and fluid compatibility.

Moreover, not all plastic ball valves are created equal. Even slight variations in design can affect performance. As you evaluate your options, keep in mind the specific needs of your project. Gathering as much information as possible will help you make an informed decision. Despite the abundance of available choices, reaching a clear conclusion is often challenging. Each project presents its own unique set of requirements.

Plastic ball valves are essential components in many applications. They control flow easily and prevent leaks. Understanding their basics can help you choose the right one for your project.

These valves are made from durable plastic materials. They resist corrosion and offer lightweight handling. Commonly used in water treatment, aquaculture, and chemical processing, they help manage various media. When selecting, consider the valve’s pressure rating and temperature tolerance. Not all plastic ball valves are created equal, and some may not withstand high-stress environments.

Tips: Always check the materials used. Some plastics may degrade over time. Ensure compatibility with the fluids in your system. For instance, PVC is great for water, while PP works well with chemicals.

Think about installation as well. Some valves have limited space for mounting. Address these details early in your planning. It’s easy to overlook, but poor installation can lead to leaks. Choosing the right valve requires careful thought and a bit of research. Don't rush the process.

Choosing the right plastic ball valves can be challenging. Several specifications play a critical role in selection. Materials are vital. Common materials include PVC, CPVC, and PP. Each material has distinct properties that can impact performance. For instance, PVC is often resistant to chemicals and suitable for many applications. However, it can become brittle over time.

Pressure ratings are equally important. Most plastic ball valves handle pressures between 100 to 200 PSI. Exceeding these limits can lead to failures. A report by the Plastics Industry Association indicates that improper pressure selection is a key failure point in valve performance. The valve size is another crucial factor. A valve that is too small can restrict flow, reducing efficiency. Studies suggest that flow rate can decrease by up to 30% if the valve is not properly sized.

Temperature tolerance is often overlooked. Different plastic materials offer various temperature limits. Exceeding these can affect the longevity and functionality of the valve. For example, PP valves can withstand temperatures up to 180°F, while PVC typically performs up to 140°F. Choosing the right plastic ball valve requires careful consideration of these specifications to avoid potential issues.

When selecting plastic ball valves for a project, understanding the materials used is crucial. Different plastics offer various benefits and drawbacks. PVC is popular for its affordability and resistance to corrosion, but it may not handle high temperatures well. In contrast, CPVC boasts superior heat resistance, making it suitable for hotter applications.

Another option is polypropylene, known for its chemical resistance and lightweight nature. However, it can be more expensive. Each material has its unique properties that may or may not align with project requirements. For example, some plastics may degrade under UV exposure, limiting their outdoor use.

Additionally, consider the intended application. Is the valve for transporting chemicals or water? This choice influences material selection. Various factors like pressure ratings and flow characteristics must also be assessed. In this complex decision-making process, it’s essential to balance cost, durability, and performance. Thus, thorough evaluation of each plastic type aids in achieving project goals.

When selecting plastic ball valves, understanding flow characteristics and pressure ratings is crucial. Different applications require specific flow rates. For instance, a system that demands high flow should utilize a valve designed for that purpose. Consider the size of the valve as well. A 1-inch valve may not suffice for large-scale systems. This can lead to pressure loss and inefficiency.

Pressure ratings also play a significant role. Each valve comes with a maximum pressure limit. Ignoring this can result in system failure. It's essential to check compatibility with your existing setup. A valve rated at 150 psi may not work well in a 200 psi application. Don’t forget to evaluate temperature ranges too. High temperatures can affect the integrity of plastic materials.

Remember, not all plastic valves are identical. Some may perform poorly under certain conditions. This inconsistency can lead to unexpected issues in your project. It’s wise to test valves in your environment before finalizing your choice. The right valve can enhance efficiency and prolong the system's lifespan. However, getting it wrong can be costly. Consider all these factors carefully.

This bar chart illustrates the flow rates in gallons per minute (GPM) for various sizes of plastic ball valves. Choosing the right valve size is crucial for ensuring optimal flow characteristics in your project.

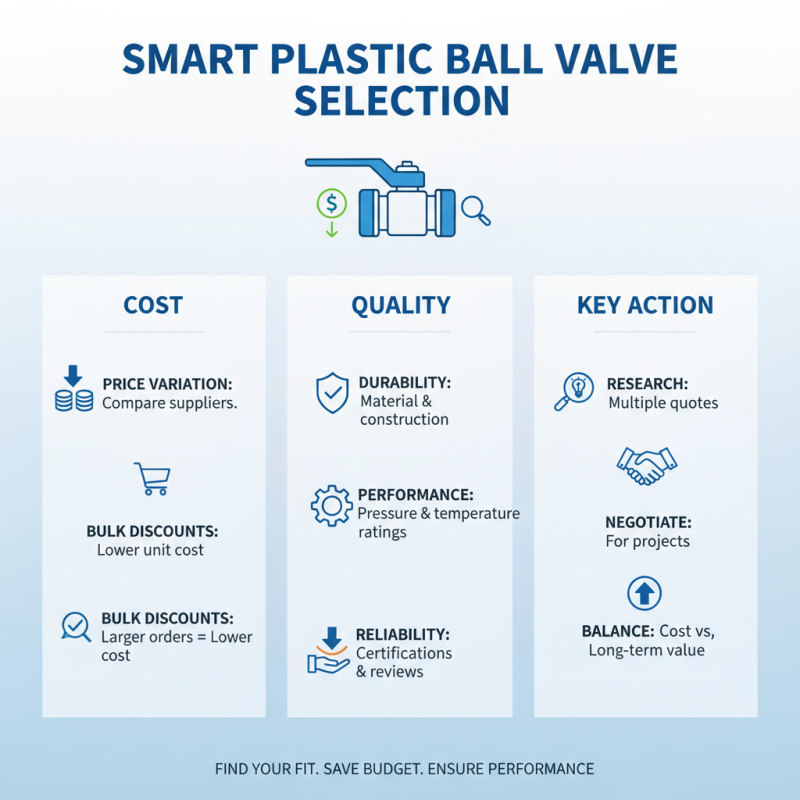

When choosing plastic ball valves for your project, cost and quality are key factors. Comparing options from various suppliers can help you find the right fit. Prices often vary significantly, impacting your budget. Do research on bulk purchase discounts. Some suppliers offer better deals for larger orders. This can lower your overall costs.

Quality is equally important. Evaluate the materials used in the valves. Look for durability and resistance to chemicals. Poor quality might lead to leaks or system failures. Ask for samples when possible. Test them before full-scale purchasing.

Tips: Always check supplier reviews. Look for feedback on product performance. A valve that seems cheap might be costly in the long run. Be wary of prices that seem too good to be true. They often indicate lower quality. Assess all options carefully.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.