When it comes to plumbing systems, the selection of the appropriate components is crucial for ensuring efficiency and longevity. Among these components, the cepex check valve stands out due to its critical role in preventing backflow and maintaining a steady flow of liquids. According to a recent report by the American Society of Plumbing Engineers, improper valve selection can lead to significant issues such as water contamination and increased system maintenance costs—estimating that up to 30% of plumbing failures are associated with valve malfunctions.

The cepex check valve, recognized for its innovative design and reliability, has become a preferred choice among professionals in the industry. With the market for check valves projected to grow at a CAGR of 5.4% by 2026, driven largely by advancements in technology and increasing demand for efficient water management, understanding how to choose the right cepex check valve for your plumbing needs is more important than ever. This guide will explore the essential factors to consider when selecting a cepex check valve, ensuring that you make an informed decision that meets your system's specific requirements.

When selecting a Cepex check valve, understanding the specifications and their applications is crucial for enhancing plumbing efficiency. A check valve's primary function is to prevent backflow in piping systems, ensuring that fluids flow in one direction. According to a report by the American Society of Plumbing Engineers (ASPE), improper selection of check valves can lead to a 20% decrease in system efficiency, highlighting the importance of choosing the right product for your specific needs.

Cepex check valves come in various materials, including PVC and CPVC, suitable for different fluids and temperatures. For instance, a study by the Plastic Pipe and Fittings Association (PPFA) indicates that PVC valves can handle pressures up to 160 psi while maintaining their integrity against corrosive materials.

Furthermore, understanding the size and connection types is vital; using the correct valve size can avoid issues such as turbulence and high-pressure drops, which can further degrade plumbing performance. By thoroughly evaluating these specifications, you can ensure optimal functionality and longevity of your plumbing systems.

When selecting the right Cepex check valve for your plumbing needs, understanding flow rates and pressure drops is crucial. According to industry reports, the optimum flow rate for a typical residential plumbing system ranges from 3 to 5 gallons per minute (GPM). This range ensures adequate water delivery without overwhelming the system. Choosing a check valve that can maintain this flow rate while effectively preventing backflow is essential. Cepex check valves are designed to accommodate varying flow rates, and selecting the correct size can prevent inefficiencies such as water hammer or reduced system performance.

Pressure drop also plays a significant role in valve selection. A study from the Hydraulic Institute highlights that a pressure drop exceeding 5% of the system's total pressure can lead to excessive energy costs and compromised valve performance. It’s recommended that plumbing professionals measure the pressure drop across the intended check valve installation site to ensure compatibility. By analyzing both flow rates and pressure drops, you can make an informed decision to choose a Cepex check valve that enhances your plumbing system’s efficiency and reliability.

| Valve Size (inches) | Flow Rate (GPM) | Pressure Drop (PSI) | Material | Operating Pressure (PSI) |

|---|---|---|---|---|

| 1 | 50 | 5 | PVC | 150 |

| 1.5 | 100 | 8 | CPVC | 200 |

| 2 | 150 | 10 | Metal | 300 |

| 3 | 200 | 15 | Brass | 400 |

When selecting the right Cepex check valve for your plumbing needs, the material choice is crucial for ensuring longevity and resistance to corrosion. Common materials for Cepex check valves include PVC, CPVC, and various metal alloys. PVC is lightweight, cost-effective, and resistant to a wide range of chemicals, making it an excellent choice for many residential applications. CPVC, on the other hand, can withstand higher temperatures, making it suitable for hot water systems. For situations where extreme conditions exist, using metal alloys like stainless steel can provide additional strength and reliability.

**Tips:**

1. Assess the chemical compatibility of the valve material with the fluids in your system. This will prevent premature degradation and costly repairs.

2. Consider temperature requirements; ensure the selected material can handle both current and potential future operating temperatures.

3. Evaluate installation environments, such as exposure to harsh weather or corrosive substances, to determine which material will best maintain its integrity over time.

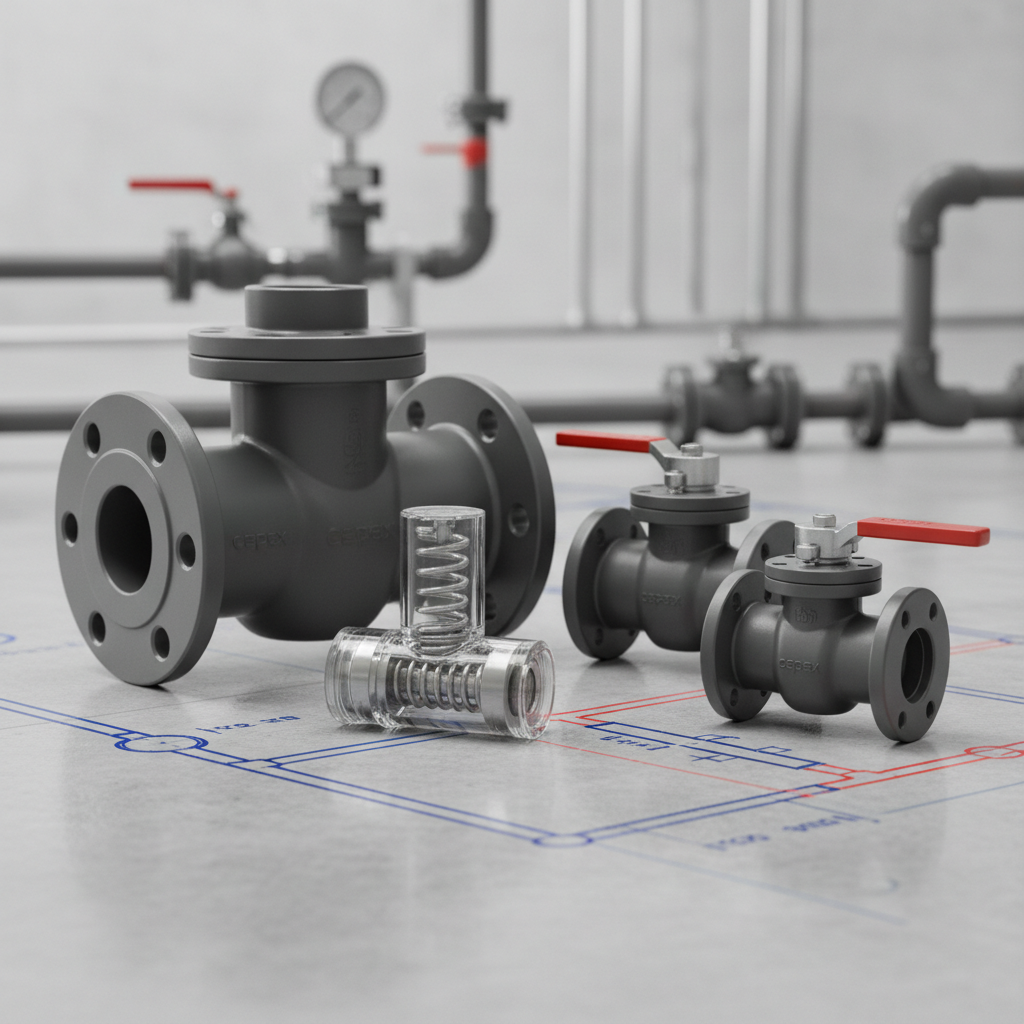

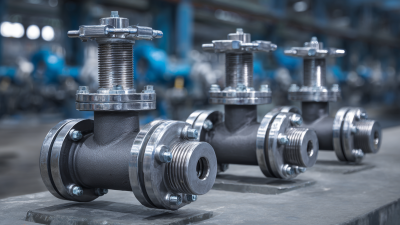

When selecting the right Cepex check valve for your plumbing project, it is essential to understand the various types available and their specific applications. Cepex offers a range of check valves, including swing, spring-loaded, and ball check valves. Swing check valves are typically used in horizontal piping systems, as their design allows for smooth flow with minimal turbulence. They are ideal for larger pipelines where backflow prevention is critical.

On the other hand, spring-loaded check valves are more versatile and can be installed in both horizontal and vertical systems. Their internal spring mechanism ensures that the valve closes tightly when flow stops, making them suitable for applications where space is limited and reliability is paramount. Ball check valves are another option, known for their robust performance and ability to handle high flow rates. Understanding your specific plumbing needs, such as pressure conditions and flow patterns, will guide you in choosing the most appropriate Cepex valve for a successful installation.

When it comes to maintaining plumbing systems, check valves play a crucial role in preventing backflow and ensuring proper water flow. However, even high-quality Cepex check valves can encounter issues over time. Common problems include leakage, valve sticking, and improper installation. According to industry reports, approximately 30% of plumbing malfunctions are attributed to faulty check valves, highlighting the importance of regular maintenance and prompt interventions.

To troubleshoot these issues effectively, it is essential to conduct routine inspections. Inspect for any signs of wear, corrosion, or accumulation of debris that may inhibit the valve's function. Additionally, following the manufacturer's recommendations for servicing can extend the life of your check valve. Replaceable components may only need minor adjustments, but if the valve is consistently failing to perform, a full replacement could be warranted.

Studies suggest that proactive maintenance can reduce plumbing repair costs by up to 40%, making it a wise investment for homeowners and professionals alike.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.