In the realm of fluid management, choosing the right fluid valves is crucial. According to Henry Thompson, an expert in the fluid valves industry, "The right valve can make or break your project." His insight underscores the importance of making informed decisions. Each project requires specific valve characteristics to ensure efficiency and safety.

Fluid valves come in various types, sizes, and materials. Understanding their functions is essential. While many might overlook these details, they significantly impact fluid flow and control. For instance, a valve that’s too small can cause pressure issues, while one that’s too large may lead to inefficient operation. It's important not to rush the selection process.

Project managers must consider several factors. Cost, durability, and compatibility with existing systems are vital considerations. The misstep here could lead to project delays or increased expenses. In a world where details matter, taking the time to evaluate options can save headaches later on. By reflecting on choices made, teams can improve future projects. Understanding fluid valves is more than just a task; it’s an essential part of fluid management.

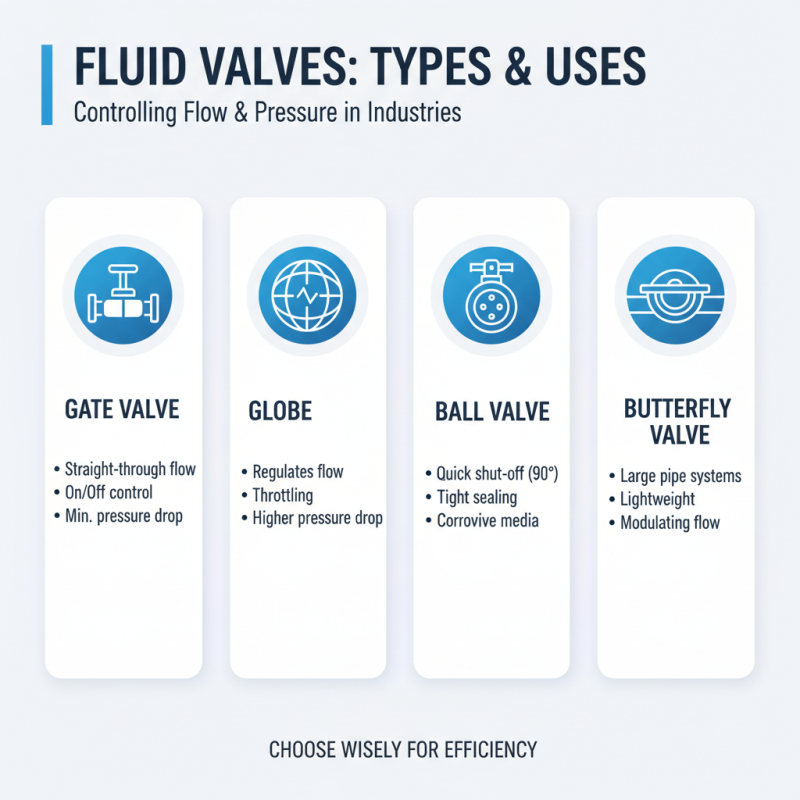

Fluid valves play a crucial role in various industries. They control the flow and pressure of liquids and gases. Understanding the types of fluid valves is essential when selecting the right one for your project. The most common types include gate, globe, ball, and butterfly valves. Each type serves a distinct purpose and can significantly impact operational efficiency.

Gate valves are often used for on/off control. They are simple and effective, yet they can be slow to open and close. Globe valves, on the other hand, provide better throttling capabilities. However, they might generate pressure drops. Ball valves enable quick shut-off. They have a simple design but can wear out with frequent use. Butterfly valves are lightweight and space-saving. They may not be suitable for all fluids due to their design limitations.

Choosing the best fluid valve is not always straightforward. Factors such as fluid type, temperature, and pressure come into play. One must consider these elements to avoid unexpected challenges. Sometimes, the right valve isn't the most expensive or complex option. Simplicity can often lead to better performance and easier maintenance.

Choosing fluid valves for a project involves several essential factors. A key consideration is the type of fluid. For example, corrosive acids require materials that can withstand harsh environments. According to a study by the Fluid Control Institute, nearly 30% of valve failures arise from incorrect material selection. Understanding the fluid's properties is crucial to avoid these costly mistakes.

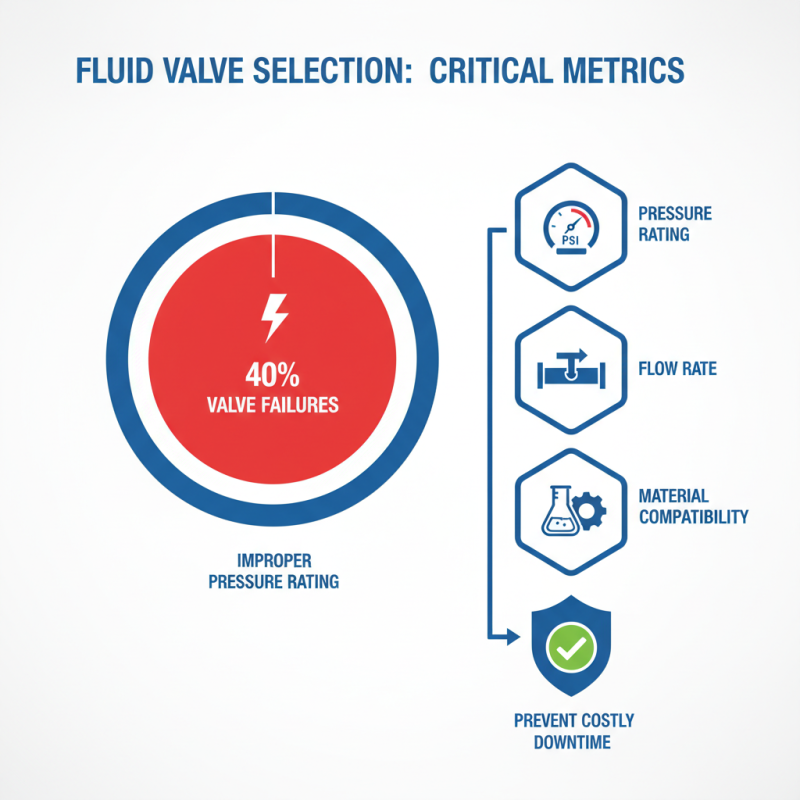

Another vital factor is the valve's pressure rating. The American Society of Mechanical Engineers states that improper pressure ratings lead to up to 20% of potential leaks in industrial settings. Users must assess the system's pressure conditions thoroughly. This is particularly important in high-pressure applications where even minor deviations can result in catastrophic failures.

Lastly, think about the maintenance requirements. Many valves need regular upkeep which can affect operational efficiency. The International Society of Automation suggests that nearly 25% of maintenance costs in process facilities could be attributed to fluid control devices. If the right valve is not chosen, businesses may face increased downtime and expenses. Therefore, careful consideration and planning in selecting fluid valves can significantly impact project success.

When selecting fluid valves, material choice is crucial. Different applications require diverse materials. For instance, stainless steel is popular in high-pressure systems. It offers rust resistance and durability. However, in corrosive environments, plastic valves may be more suitable. They provide excellent resistance to chemicals but can be less robust.

Consider the operating temperature as well. Metals can handle extreme temperatures better than plastics. But, plastics can offer lightweight solutions for less demanding conditions. What about the costs? Often, budget constraints impact material decisions. Cheaper options may lead to frequent replacements. This can incur higher costs in the long run.

Additionally, the compatibility of the fluid with the valve material matters. Some fluids can degrade certain materials over time. Testing and research are essential before making a final decision. Sometimes, combining materials can enhance performance. Yet, this can complicate the design process. Careful consideration is needed to avoid costly mistakes.

When selecting fluid valves for projects, evaluating performance metrics is crucial. Key specifications include pressure rating, flow rate, and material compatibility. According to industry reports, 40% of valve failures are due to improper pressure ratings. Understanding these metrics can prevent costly downtimes.

Flow rate is another critical factor. Reports indicate that miscalculating flow requirements can lead to inefficient systems. A valve that is too restrictive can create pressure drops that affect performance. It's essential to analyze the specific needs of your project. Consider the mediums involved, whether they are abrasive or non-corrosive.

Material choice greatly impacts durability and performance. For example, stainless steel is often recommended for corrosive environments. However, it may not be necessary in all cases. Choosing the wrong material can lead to premature failure. Regular evaluations and adjustments based on project requirements can ensure optimal valve performance.

When selecting fluid valves for your project, regulatory compliance is essential. Each industry has specific standards. Failing to meet these can result in costly delays. Understanding the governing regulations can be complex. It's important to know which standards apply to your specific application. This includes safety requirements and performance benchmarks.

Documentation should accompany every valve selection. This means having certificates and compliance reports. Regulatory bodies often demand rigorous testing. This ensures valves operate safely under various conditions. Many standards exist, including those for pressure and temperature ratings. A misunderstanding can lead to project setbacks or safety hazards.

Keep in mind that not all valves are created equal. Quality can vary significantly. Flaws hidden within the design may not be immediately apparent. Regular audits can help identify potential issues. Reflection on past projects is vital. Consider what went wrong and why. Learning from these experiences can improve future choices.

| Valve Type | Material | Pressure Rating (PSI) | Temperature Range (°F) | Regulatory Standards Compliance |

|---|---|---|---|---|

| Ball Valve | Stainless Steel | 1500 | -20 to 400 | ANSI, ASME |

| Gate Valve | Carbon Steel | 2000 | -20 to 300 | API, ISO |

| Globe Valve | Brass | 600 | -40 to 250 | ASME, API |

| Check Valve | PVC | 150 | 32 to 140 | ANSI, NSF |

| Butterfly Valve | Ductile Iron | 300 | -20 to 250 | AWWA, API |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.