Check valves play a crucial role in various industries by ensuring the unidirectional flow of fluids and preventing backflow, which can lead to critical system failures. According to a recent market research report by Global Industry Analysts, the global check valve market is projected to reach approximately $2.5 billion by 2026, reflecting a growing demand in sectors such as water treatment, oil and gas, and chemical manufacturing. The increasing emphasis on maintenance and efficiency in fluid handling systems has further fueled this growth.

Check valves play a crucial role in various industries by ensuring the unidirectional flow of fluids and preventing backflow, which can lead to critical system failures. According to a recent market research report by Global Industry Analysts, the global check valve market is projected to reach approximately $2.5 billion by 2026, reflecting a growing demand in sectors such as water treatment, oil and gas, and chemical manufacturing. The increasing emphasis on maintenance and efficiency in fluid handling systems has further fueled this growth.

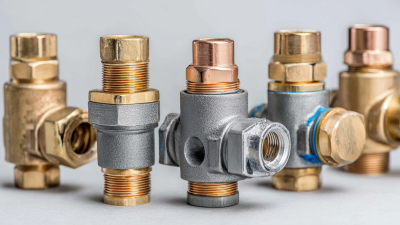

Expert Mark Holloway, a renowned figure in the field of fluid dynamics and valve technology, states, "Check valves are essential in maintaining system integrity and operational efficiency, particularly in high-demand applications." With their diverse types, including swing, spring-loaded, and ball check valves, these components are designed to fulfill specific operational requirements. As industries evolve, understanding the different types, functions, and applications of check valves becomes imperative for engineers and decision-makers alike, ensuring optimized performance and reliability in diverse systems.

A check valve, often referred to as a non-return valve, is a crucial component that allows fluid to flow in only one direction, effectively preventing backflow. This mechanism is vital in various applications, from plumbing to industrial processes, ensuring safety and efficiency. According to a report by the Global Check Valve Market, the demand for these valves is expected to grow at a CAGR of 5.2% from 2021 to 2028, driven by augmented applications in water treatment and oil & gas industries.

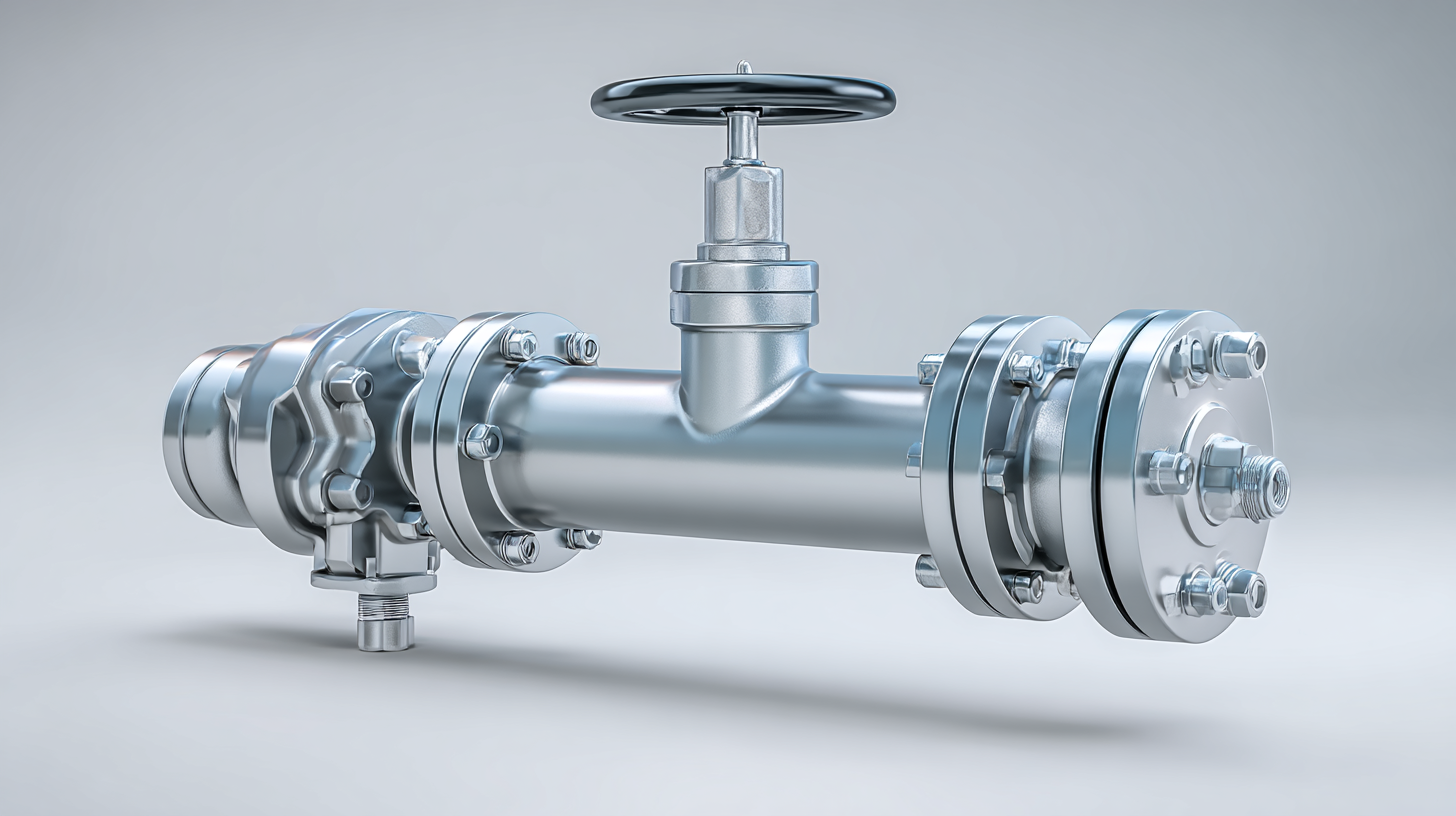

The primary mechanism behind a check valve is the use of a disc or ball that moves within the valve body to block reverse flow. When fluid pressure from the inlet side exceeds that on the outlet side, the valve opens, allowing flow to proceed. This simple yet effective design minimizes the risk of damage caused by backflow, which is particularly vital in maintaining system integrity and preventing contamination in sensitive applications.

**Tips:** Always choose the correct type of check valve—like swing, lift, or ball—based on your specific application to ensure optimal performance. Regular maintenance checks will also help in identifying wear and tear, prolonging the lifespan of your system.

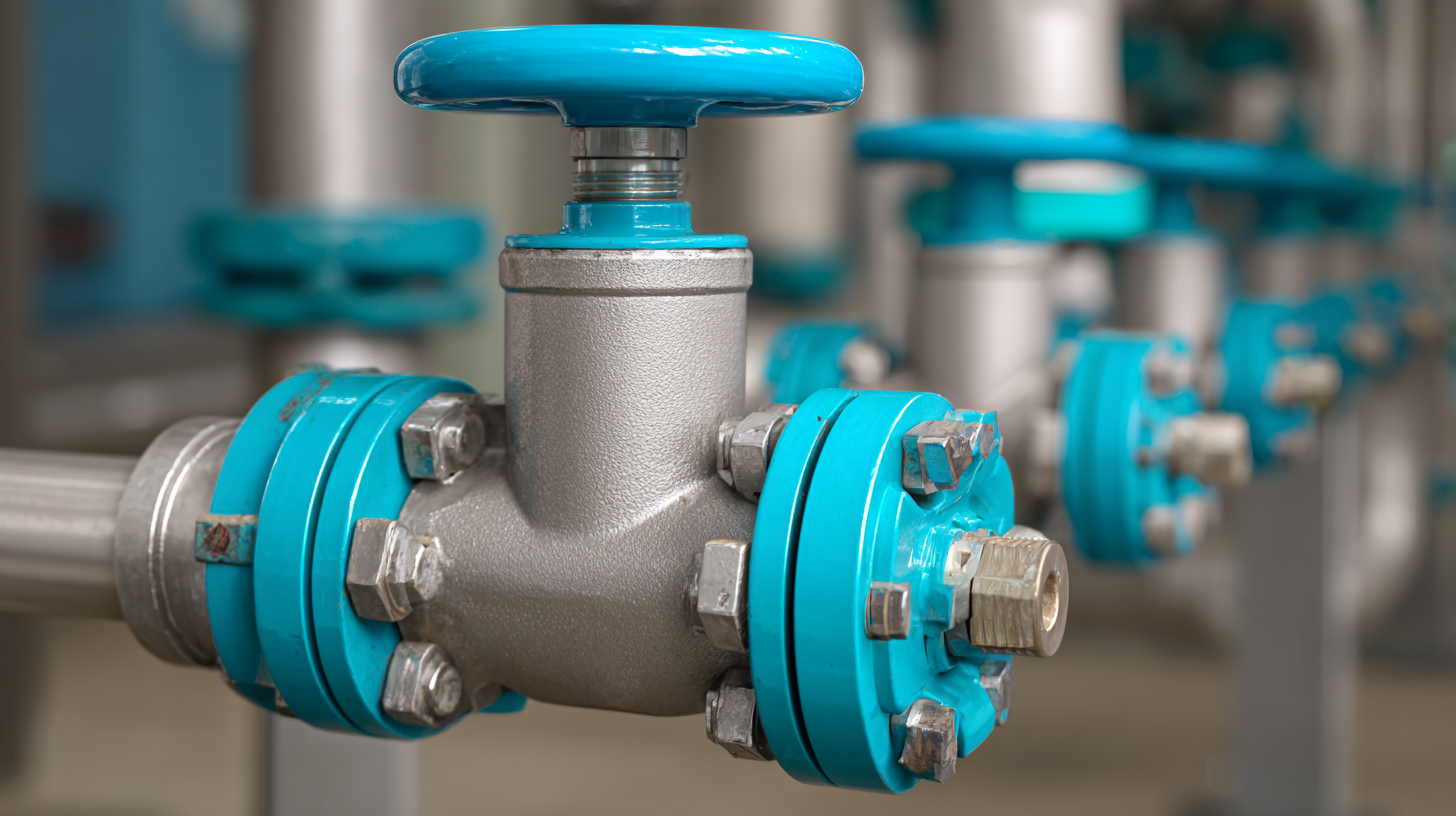

Check valves play a crucial role in various industries by ensuring the unidirectional flow of fluids and preventing backflow. Among the key types of check valves, the swing check valve operates by swinging a disc onto a seat, allowing fluid to flow in one direction while remaining tightly closed against backflow. Another popular type is the lift check valve, where the disc moves vertically to open or close, making it suitable for high-pressure applications. Additionally, there are diaphragm check valves, which utilize a flexible membrane to control flow, often used in sanitary applications due to their leak-proof design.

Tips: When selecting a check valve, consider factors like the fluid type, pressure conditions, and installation environment for optimal performance. Regular maintenance checks can also prolong the life of your check valves, ensuring they function effectively over time. Additionally, staying updated on innovations in check valve technology, such as hydrogen valve advancements, can enhance operational efficiency and safety in various applications.

| Check Valve Type | Function | Application | Advantages | Disadvantages |

|---|---|---|---|---|

| Swing Check Valve | Allows flow in one direction; swings open and closed. | Water supply systems, wastewater treatment. | Simple design, low pressure drop. | Can be noisy, sensitive to the speed of fluid. |

| Lift Check Valve | Uses a sliding disc to prevent backflow. | Oil and gas pipelines, chemical processing. | Effective for high pressure systems, compact design. | Requires a certain amount of flow to operate effectively. |

| Ball Check Valve | Uses a ball to block reverse flow. | Slurry applications and drainage systems. | Minimal leakage, suitable for various media. | May be affected by debris, installation can be tricky. |

| Diaphragm Check Valve | Uses a flexible diaphragm to control flow. | Food and beverage industry, pharmaceutical applications. | Good sealing capability, can handle viscous fluids. | Limited pressure and temperature range. |

| Spring Check Valve | Uses a spring-loaded mechanism to prevent backflow. | HVAC systems, fuel oil systems. | Fast response time, reliable in various positions. | Increased complexity, potential for spring fatigue. |

Check valves play a crucial role in various industries by ensuring safe and efficient fluid flow. These devices allow fluid to flow in only one direction, preventing backflow that can cause equipment damage and system inefficiencies. According to a report by MarketsandMarkets, the global check valve market is expected to grow from USD 6.5 billion in 2020 to USD 8.6 billion by 2025, reflecting the increasing demand for safe fluid management across sectors such as oil and gas, water treatment, and chemical processing.

In oil and gas applications, for instance, check valves are essential for protecting pumps and compressors from reversal of flow due to pressure changes. The American Petroleum Institute (API) emphasizes that proper maintenance and functioning of check valves can significantly reduce operational risks and ensure compliance with safety standards. Furthermore, in the water treatment sector, these valves help maintain system integrity by preventing contamination, which is vital given that over 2 billion people worldwide lack safe drinking water according to the World Health Organization. The implementation of effective check valves is thus fundamental in enhancing both safety and operational efficiency in fluid systems across these diverse industries.

Check valves play a crucial role in various sectors, particularly in the water, oil, and gas industries. These devices ensure that fluid flows in one direction while preventing backflow, which can lead to significant operational inefficiencies and safety hazards. In the water sector, check valves are typically employed in irrigation systems and municipal water supply lines to maintain pressure and prevent contamination. Their reliability directly impacts the efficiency of water distribution and management systems.

In the oil and gas sector, the use of check valves is vital for maintaining system integrity during extraction and transportation processes. They help mitigate risks associated with pressure fluctuations and potential leaks, thereby enhancing safety in high-stakes environments. The applications extend to various components throughout the production and distribution processes, ensuring the smooth operation of pipelines and storage facilities. As global demand for energy continues to rise, the importance of robust and well-functioning check valves in these industries only becomes more pronounced.

The check valve market is becoming increasingly relevant in global manufacturing systems, coinciding with the growing demand in associated industries like motor starters and control valves. According to market research, the global motor starters market is projected to reach a size of USD 12.8 billion by 2034, growing at a compound annual growth rate (CAGR) of 5.8%. This trend reflects an ongoing investment in automation and efficiency, where check valves play a crucial role in ensuring fluids move in a single, intended direction, preventing backflow, and protecting other components in various systems.

As the manual control valve market forecasts a robust growth to USD 4.8 billion by 2035, with a remarkable CAGR of 7.6%, businesses must grasp the importance of integrating these systems to streamline operations. When selecting check valves, consider factors such as the application environment, required pressure ratings, and the type of fluid being handled.

Additionally, with the valve remote control system market already exceeding USD 8.6 billion and expecting a growth rate of 6.5% through 2034, the focus on safety and efficiency becomes paramount. Tips to enhance valve performance include regular maintenance checks, ensuring proper installation to avoid leaks, and utilizing the right materials to withstand environmental conditions.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.