The cepex ball valve is pivotal in various industrial applications. It offers many benefits that enhance efficiency and safety. In 2026, understanding these advantages becomes even more essential for professionals in the field.

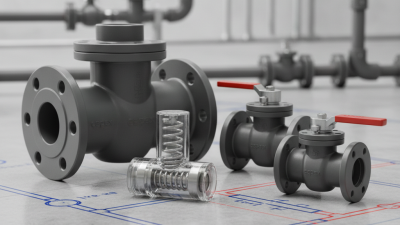

These valves are designed with durability and reliability in mind. Their quality construction allows for seamless operations under high pressure and temperature. Many industries rely on cepex ball valves for their robust performance.

However, not all cepex ball valves meet the highest standards. It's crucial to evaluate the specific model you choose. Many factors, like material and design, affect performance. Users often overlook these details, leading to operational challenges. Awareness of the cepex ball valve's features can guide better decisions in 2026 and beyond.

In fluid control systems, ball valves play a crucial role. Their design allows for efficient regulation of flow. They offer a quick shut-off mechanism. This is particularly useful in emergencies. A simple quarter-turn provides reliable control.

One key advantage is their durability. Ball valves can handle high pressures. This is important in many industrial applications. They are also resistant to corrosion, increasing their lifespan. Maintenance is relatively straightforward due to their robust construction.

Tips: Always consider the specifics of your system before selecting a valve. If unsure, consult with an expert. Proper installation is essential for peak performance. Regular checks can help avoid costly failures. On the other hand, even the best valve can wear over time. Always keep an eye on performance indicators.

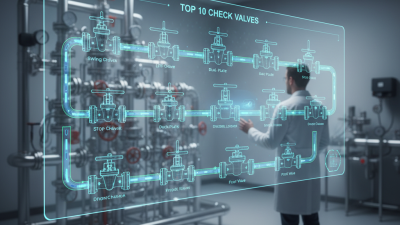

This chart represents the top 10 advantages of Cepex ball valves in fluid control systems, rated on a scale from 1 to 10. Each benefit showcases the strengths of using these ball valves in various applications.

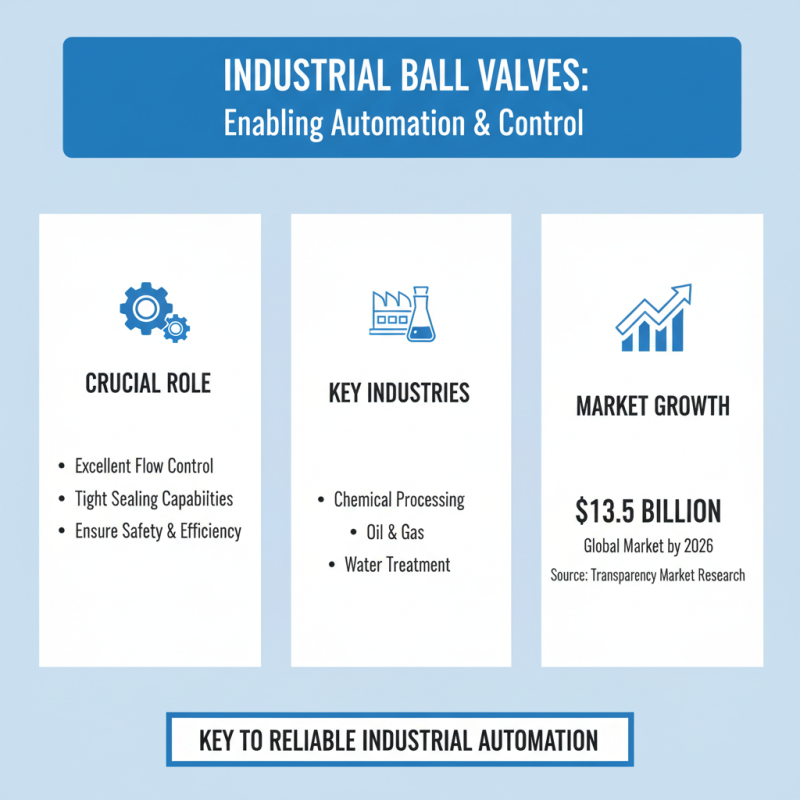

Ball valves play a crucial role in industrial applications. They provide excellent flow control and tight sealing capabilities. In industries such as chemical processing, oil and gas, and water treatment, ball valves ensure safety and efficiency. According to a recent report by Transparency Market Research, the global ball valve market is expected to reach $13.5 billion by 2026. This growth highlights the increasing reliance on automation and control systems in various processes.

In water treatment, for example, ball valves are used to manage the flow of water through treatment plants. Their compact design allows for easy installation and maintenance. Reportedly, around 20% of all industrial water applications utilize ball valves. This efficiency reduces downtime and minimizes costs. However, operators need to monitor valve performance regularly. Regular maintenance is essential to prevent leaks and ensure optimal operation.

In the oil and gas sector, ball valves are critical for controlling the flow of crude oil and natural gas. They can withstand high pressures and temperatures. The global oil and gas industry aims to reduce operational costs by about 15% by 2026. This goal often relies on advanced valve technology. However, there is still a need for proper training. Employees must understand the specific requirements of ball valve maintenance and operation to minimize risks.

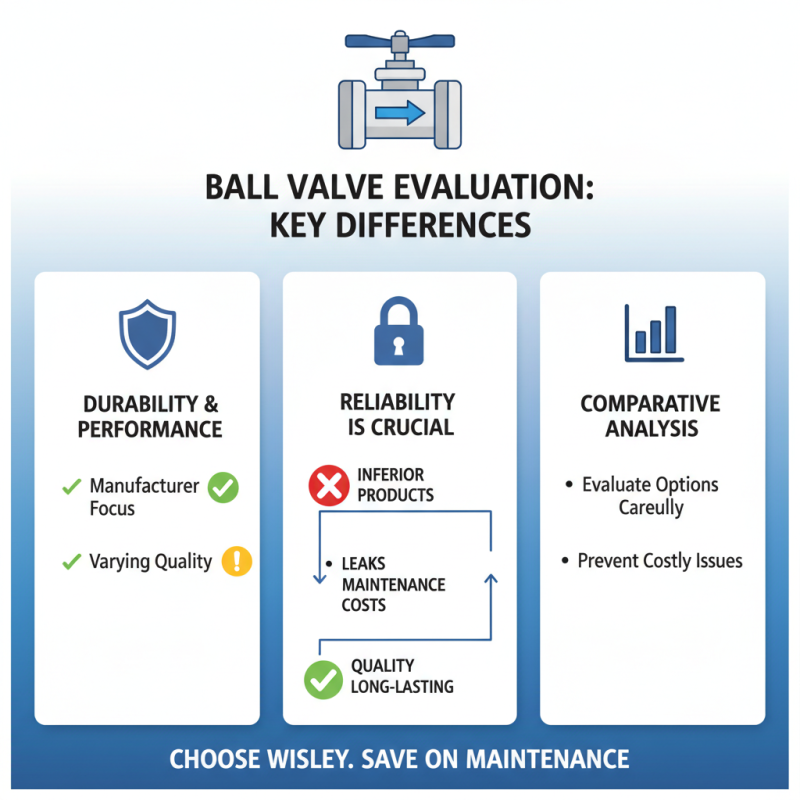

When evaluating ball valves, a comparative analysis reveals distinct differences among various options. Many manufacturers focus on durability and performance, yet some fall short. Reliability is crucial; inferior products often lead to leaks, increasing maintenance costs.

Material quality plays a significant role in valve performance. Some brands use subpar materials, resulting in vulnerability to corrosion. In contrast, others ensure their valves are constructed with reliable, resistant materials. This contributes to longevity in various environments, from residential to industrial.

Another essential aspect is design. Many valves feature ergonomic designs for easier operation. However, there are instances where functionality is sacrificed for aesthetics. A well-designed valve should offer both ease of use and effectiveness. Ultimately, the decision rests on balancing quality, performance, and price. Make careful comparisons to find a valve that meets your needs.

In 2026, the efficiency of ball valves is heavily influenced by

technological innovations. Advanced materials are changing the

durability and performance of these valves. For instance, high-performance polymers enable resistance

to extreme temperatures and chemicals. This leads to increased lifespan and reduced maintenance costs.

A recent industry report indicates that using advanced materials can enhance valve lifespan by up to

35%.

Automation is another key driver. Smart techniques, such

as IoT integration, allow for real-time monitoring. This technology helps identify potential issues

before they escalate, reducing downtime. In fact, efficiency improvements from automation can

increase system performance by 20%. However, there's room for improvement.

Training staff on new technologies is often overlooked but crucial. Many companies struggle with

integrating these advanced systems due to a skills gap in their workforce.

The demand for energy-efficient solutions is reshaping the valve

market. The push for lower emissions and energy costs creates opportunities for innovative designs.

However, not all new technologies prove reliable. User experience feedback is essential

for optimizing these tools. Balancing innovation with practicality remains a challenge. Industry analysts suggest

continuous evaluation to ensure that benefits align with user needs.

The market for ball valves, particularly Cepex models, has shown significant growth in recent years. In 2022, the global ball valve market was valued at around $10 billion. Forecasts suggest it will reach approximately $14 billion by 2026, reflecting a compound annual growth rate (CAGR) of about 6.5%. This growth is driven by sectors like oil and gas, chemicals, and water management.

A recent report indicated that nearly 70% of all ball valve applications are in fluid control systems. This is crucial for industries requiring precise flow regulation. The rise in infrastructure developments globally is also a contributing factor. However, there are challenges. Not all manufacturers adhere to high-quality production standards. This inconsistency can lead to failures in critical applications. Many clients still face difficulties in selecting the right valve for specific needs.

Data from a 2023 industry survey revealed that only 50% of users are satisfied with their valve solutions. This indicates room for improvement in providing information and support. Customers often complain about unclear specifications. They need better guidance to choose the right products. The need for education and better resources is evident, especially with the expected market expansion.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.