When choosing PVC fittings for plumbing projects in 2026, understanding the market is essential. According to expert James Carter, "Quality PVC fittings can make or break your plumbing system." This highlights the importance of selecting the right materials. PVC fittings are widely recognized for their durability and cost-effectiveness.

There are many options available today. However, not all PVC fittings are created equal. It's crucial to consider factors like size, pressure ratings, and compatibility. Some fittings may promise durability but fail under high pressure. Real-world experiences can reveal shortcomings that might not be obvious at first glance.

Choosing the ideal PVC fittings involves careful consideration. Each project has unique requirements. Some fittings may serve their purpose well initially but could cause issues later on. It's vital to research and reflect on past experiences. Reliable reviews and expert opinions can guide better choices, ensuring successful plumbing projects.

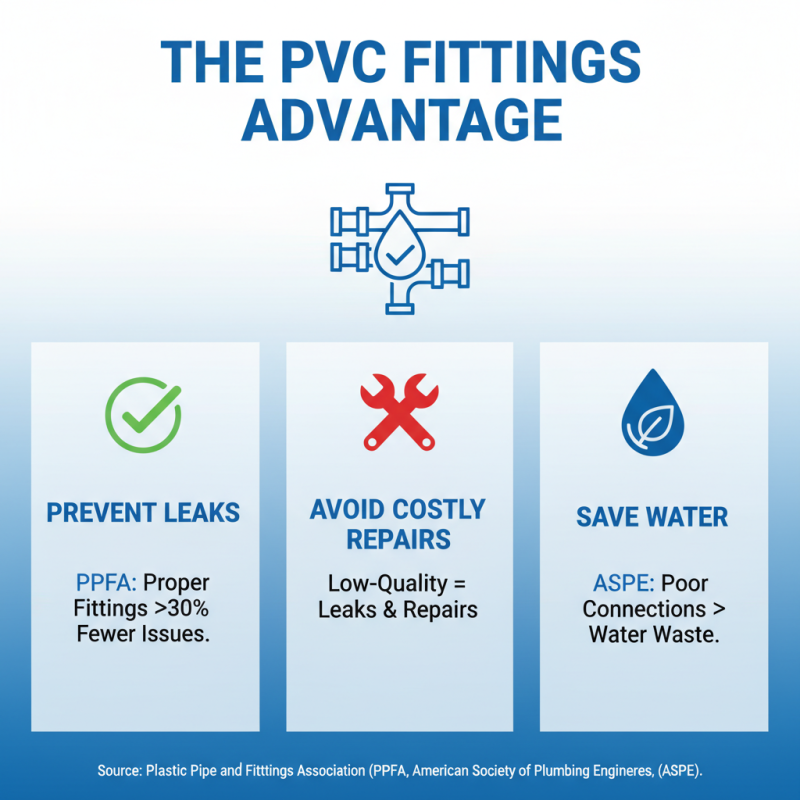

Choosing quality PVC fittings is critical in plumbing. According to the Plastic Pipe and Fittings Association (PPFA), proper fittings can prevent over 30% of common plumbing issues. Low-quality fittings often lead to leaks and costly repairs. A study by the American Society of Plumbing Engineers (ASPE) revealed that poor connections are a leading cause of water waste in residential areas.

When selecting PVC fittings, look for durability and reliability. The best options can withstand high pressure and temperature fluctuations. They should also be resistant to corrosion and chemicals. Many installers overlook the importance of certifications, leading to unsafe plumbing systems. Sometimes, these overlooked details become significant problems down the line.

Consider the environmental impact too. Non-compliant fittings may contribute to waste. In fact, recycled materials used in high-quality fittings can reduce plastic waste significantly. Prioritize efficiency and longevity in your projects. The right choices lead to sustainable plumbing systems, saving resources and money.

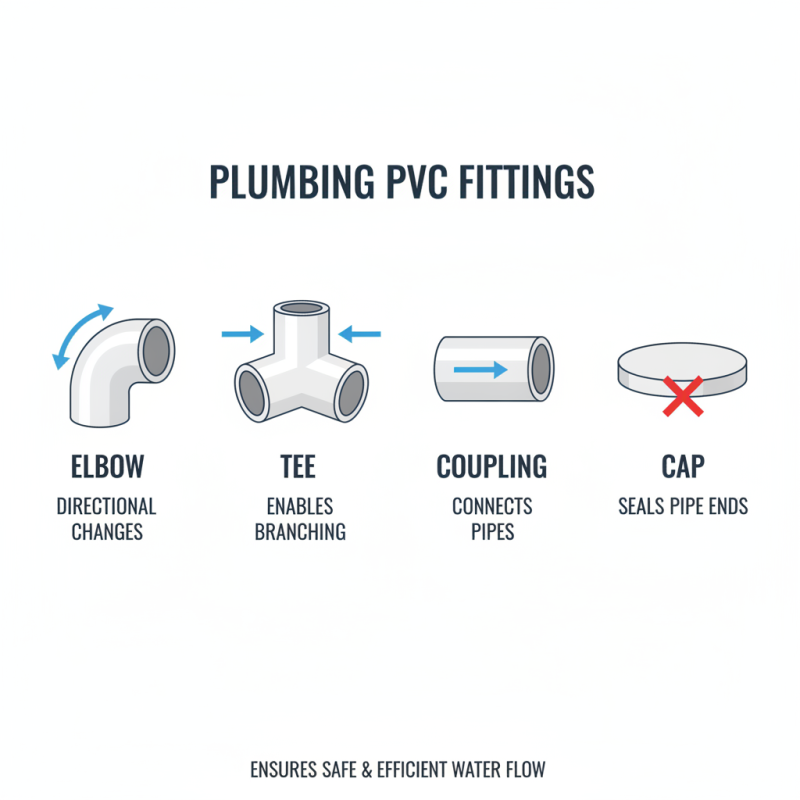

When it comes to plumbing projects, understanding the types of PVC fittings is essential. PVC fittings connect pipes, ensuring water flows safely and efficiently. Common types include elbows, tees, couplings, and caps. Each type has a specific purpose. Elbows allow for directional changes, while tees enable branching in plumbing systems.

Choosing the right fitting can be tricky. Measure accurately before making a selection. The wrong size can lead to leaks. Trust your instincts but verify your choices. Consider the environment where the fittings will be used. Some PVC is better for high-pressure areas.

Tips: Always dry-fit your fittings first. This helps you see how everything fits together. Don't rush the installation process. Make adjustments as needed. Remember, a poorly installed fitting can cause major issues down the line. Proper sealing is crucial; cheap alternatives often lead to costly repairs. Invest time in your project to prevent future headaches.

When selecting PVC fittings for plumbing projects, durability is paramount. Look for materials with a high impact resistance, which is typically measured by tensile strength. Recent industry analysis highlights that fittings made from schedule 40 PVC can withstand pressures up to 140 PSI, making them suitable for various applications. This strength is vital in preventing leaks and failures.

It's also important to consider UV resistance. Some PVC fittings are not designed for prolonged sun exposure. Reports indicate that continuous exposure to UV light can weaken these materials over time. This leads to brittleness and potential breaks. Additionally, pay attention to the chemical resistance ratings. Fittings that can withstand common chemicals found in household plumbing will last longer, reducing the need for frequent replacements.

Despite these features, not all PVC fittings on the market are created equal. Some may have flaws, such as poor mold designs. These defects can lead to leaks or installation difficulties. It's essential to scrutinize the manufacturing standards of the products you choose. Relying on industry certifications can be a helpful step in ensuring the reliability of your materials. Remember that even small lapses in quality control can result in significant long-term issues.

This chart illustrates the key features to consider for durability in PVC fittings. The data compares the percentage of users prioritizing certain features for their plumbing projects in 2026.

Choosing the best PVC fittings for your plumbing projects is essential. In 2026, several top brands stand out. These brands focus on durability and reliability. Many offer a range of fittings for various applications. Think about what you need for your project. Do you require fittings for hot water systems or cold? Each type of fitting has its own specifications.

Look for options in common sizes. Sizes like 1 inch or 2 inches are frequently used. Most homes utilize these dimensions. Explore different styles like elbows, tees, and couplings. Some fittings have extra features, such as threaded ends for easier connection. Small details matter and can improve installation.

Budget considerations are key. High-quality items can be costly, but they often last longer. Cheap fittings might save money upfront but could lead to failures. Be mindful of reviews and recommendations. Real-world experiences can help you make informed decisions. Remember, not all products work perfectly every time. It’s essential to consider the installation environment, too. Not everything is straightforward.

When working with PVC fittings, precision in installation is crucial. Proper cutting and fitting of pipes lead to fewer leaks. A recent industry report noted that 70% of plumbing issues arise from improper installation. Ensuring clean cuts and using appropriate solvents can easily mitigate these issues. It’s vital to clean all surfaces effectively before applying adhesives.

Temperature affects the integrity of PVC fittings. If the environment is too cold or too hot, the performance can decline. Studies show that glue application at temperatures above 32°F yields better results. Working at optimal temperatures reduces the chance of failure. Even small mistakes can result in significant issues later.

Testing the joints after installation is often overlooked. Many forget to do this step, leading to regrets down the line. Water pressure tests can identify weak spots before walls and floors are sealed. Always address any bubbles or weak seals immediately. Attention to these details saves both time and money in the long run.

| Type of Fitting | Diameter (inches) | Schedule | Use Case | Installation Tips |

|---|---|---|---|---|

| PVC Elbow | 2 | Schedule 40 | Changing direction of pipes | Use PVC cement for a strong bond. |

| PVC Tee | 3 | Schedule 40 | Branching off a main line | Ensure proper alignment for water flow. |

| PVC Coupling | 4 | Schedule 40 | Joining two pipe sections | Apply primer before cementing for better adhesion. |

| PVC Cap | 2 | Schedule 40 | Sealing the end of a pipe | Ensure it's properly fitted before cementing. |

| PVC Adapter | 3 | Schedule 40 | Connecting different types of pipes | Tighten connections and seal with Teflon tape. |

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.