In industrial applications, the efficiency of fluid transport and management plays a critical role in ensuring optimal performance and productivity. Fluid valves are essential components that facilitate precise control over the flow of liquids and gases within various systems. Their functionality extends beyond mere regulation; high-quality fluid valves significantly influence operational efficiency, safety, and cost-effectiveness in industrial processes. Selecting the best fluid valves for specific applications can significantly impact energy consumption and resource management, making it a crucial consideration for engineers and facility managers alike.

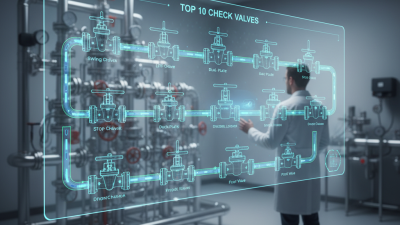

This article explores the top ten fluid valves that excel in providing efficient flow control in various industrial contexts. By examining the key features and advantages of these valves, we aim to equip professionals with a comprehensive understanding of how to enhance their systems' performance. Whether dealing with water, steam, or chemicals, the right fluid valve can ensure a seamless flow, reduce maintenance costs, and prolong the lifespan of equipment. Understanding the characteristics that contribute to the effectiveness of fluid valves is essential for making informed decisions and optimizing operational capabilities in the ever-evolving industrial landscape.

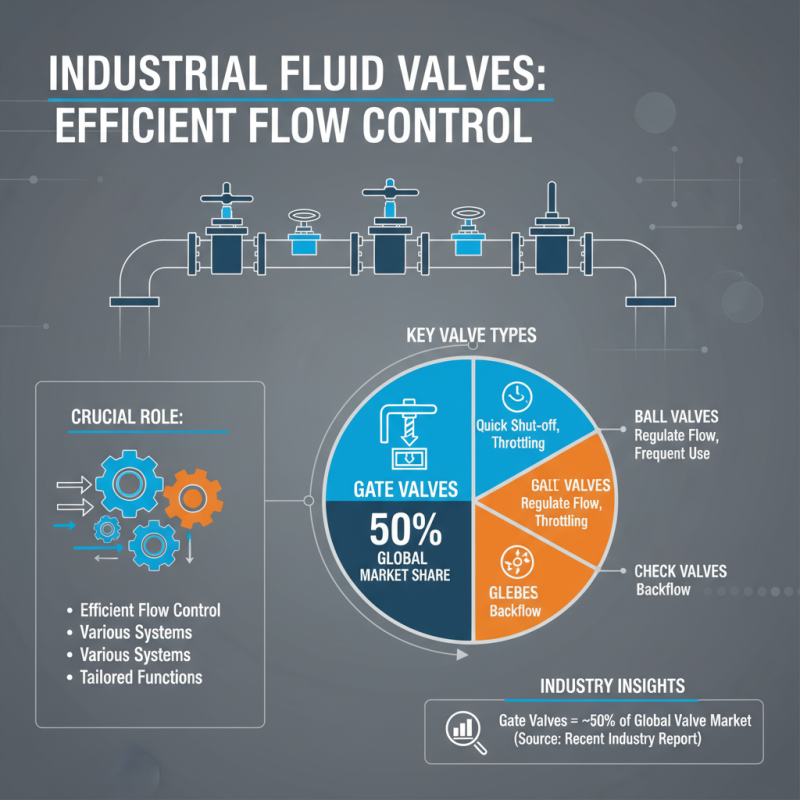

In industrial applications, fluid valves play a crucial role in ensuring the efficient control of flow within various systems. There are several types of fluid valves, each designed to serve specific functions tailored to different types of fluids, pressure conditions, and operational environments. For instance, gate valves are widely utilized for on/off control of flow, making them ideal for situations where minimal pressure drop is required. According to a recent industry report, gate valves make up approximately 50% of the global valve market, underscoring their significance in fluid management systems.

Another common type is the globe valve, which is primarily used for throttling flow. The design of globe valves allows for fine control over flow rates, making them suitable for processes that require precise adjustments. As noted in a 2022 market analysis by a leading research firm, the demand for globe valves is expected to grow at a compound annual growth rate (CAGR) of 6% over the next five years, driven by their application in petrochemical plants and power generation facilities.

Furthermore, ball valves are favored for their excellent sealing capabilities and quick operation, which makes them particularly useful in applications where fluid isolation is critical. The versatility of ball valves, combined with their durability, has led industry experts to predict an increase in their adoption across various sectors. As energy efficiency becomes a priority in industrial operations, these valves are expected to play an essential role in optimizing flow control and enhancing process reliability.

When selecting fluid valves for industrial applications, several key factors must be considered to ensure efficiency and optimal performance. First and foremost, the type of fluid being controlled is crucial. Different fluids, whether gaseous, liquid, or even slurries, require specific valve designs and materials to handle their unique characteristics. Corrosion resistance, temperature tolerance, and pressure ratings should be aligned with the application's requirements to avoid premature failure or inefficiency.

Another important factor is the valve’s flow characteristics. Different valve types, such as globe, ball, or butterfly valves, offer varying levels of flow control and pressure drop. Understanding the flow requirements of your system allows for a more tailored selection that meets performance standards while maintaining energy efficiency. Additionally, the size and layout of your piping system can influence the valve choice, ensuring that it integrates seamlessly without causing bottlenecks.

**Tips:** Always consult with a reliable professional or engineer to assess the specific needs of your system before making a decision. Furthermore, consider investing in valves with features such as automation and remote monitoring that contribute to streamlined operations and maintenance efficiency. Lastly, ensure thorough testing and evaluation during installation to avoid unexpected performance issues down the line.

This chart represents the flow efficiency percentages of various fluid valve types commonly used in industrial applications. Selecting the right valve type can greatly enhance flow control efficiency, which is crucial for optimal operations.

In the realm of industrial fluid control, selecting the right valve can significantly impact efficiency and operational costs. The best fluid valves exhibit features that cater to diverse applications, such as high-pressure resistance, temperature capabilities, and accurate flow regulation. According to recent industry reports, improper valve selection can lead to losses of up to 30% in flow efficiency, emphasizing the importance of understanding valve specifications and benefits in optimizing system performance.

When comparing fluid valves, consider aspects like material compatibility, pressure ratings, and actuation methods. For instance, regulators made from corrosion-resistant materials are essential for chemical handling, while high-performance ball valves provide excellent sealing and flow regulation. Automation trends indicate that actuated valves can enhance responsiveness, reducing response times by approximately 40%, which is critical in dynamic environments.

Tips: Ensure to analyze your system's requirements thoroughly and consult technical datasheets for valve specifications to prevent flow issues. Additionally, periodic maintenance of valves can preserve their functionality and extend their lifespan, ultimately ensuring sustained operational efficiency in fluid systems.

In the realm of industrial applications, the performance of fluid valves significantly impacts operational efficiency and flow control. Different industrial settings, such as manufacturing plants, oil and gas facilities, and chemical processing units, require specific valve characteristics to effectively manage fluid dynamics.

For example, pneumatic valves excel in environments that demand rapid response times, while electric control valves offer precise flow regulation, making them ideal for applications involving complex process controls.

Moreover, the choice of valve materials and designs can dramatically alter performance outcomes. In corrosive environments, for instance, valves made from stainless steel or specialized polymers not only enhance durability but also ensure safety and reliability. On the other hand, in high-temperature settings, metal-seated valves typically maintain integrity better than their plastic counterparts.

Thus, evaluating the performance of different valve types in selected industrial applications provides invaluable insights, enabling facility managers to make informed decisions that optimize operational workflows and minimize costs.

Ensuring optimal performance of fluid valves is vital for maintaining efficient flow control in industrial applications. Regular maintenance not only prolongs the lifespan of valves but also prevents costly downtime. One crucial tip for maintaining fluid valves is to conduct routine inspections for any signs of wear and tear.

Check for leaks, corrosion, or any blockages that may hinder operation. Early detection of these issues can save significant repair costs and enhance the overall performance of your system.

Additionally, ensuring that the valve seals and gaskets are in good condition is essential. Over time, seals can degrade due to exposure to harsh chemicals or extreme temperatures, leading to leaks and inefficiencies. It’s advisable to replace them periodically and select materials that are compatible with the fluids being handled.

Regular lubrication of moving parts is another key practice to minimize friction and wear, ensuring smooth operation.

Lastly, keeping a clean environment around valves contributes to their longevity. Accumulated debris and sediment can cause malfunctions or damage. Implementing a routine cleaning schedule can help maintain optimal conditions, allowing your fluid valves to function effectively. By following these maintenance tips, industries can enhance their fluid control systems and reduce the likelihood of unexpected failures.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.