When it comes to plumbing, choosing the right components is crucial. Compression fittings are essential for creating secure connections in various plumbing systems. These fittings are designed to compress around pipes, ensuring a tight seal. However, not all compression fittings are created equal.

In 2026, many options are available for homeowners and professionals alike. Some fittings are made from durable materials, while others may not hold up over time. It's vital to evaluate what works best for your specific needs. There’s a wide variety of designs and sizes, so selecting the right one can be overwhelming.

The best compression fittings can enhance reliability in your plumbing. Yet, many people overlook this detail. A poor choice can lead to leaks or plumbing failures. Understanding the different types and their applications is key to making informed decisions. By exploring the leading options for 2026, you can equip yourself with the knowledge to tackle any plumbing task with confidence.

Compression fittings are essential components in plumbing systems. They join two pipes securely without needing soldering or welding. These fittings are convenient for homeowners and professionals alike. They work by compressing a ferrule against the pipe, creating a tight seal that prevents leaks. This method is often preferred in situations where a quick fix is needed.

Using compression fittings can simplify many plumbing tasks. They are ideal for various materials, including copper, plastic, and steel. However, improper installation can lead to issues. Over-tightening can damage the fittings, while under-tightening can result in leaks. It’s crucial to get the installation just right, which often requires practice and patience. You might find that one small adjustment can make a significant difference in ensuring a leak-free connection.

Visualizing the parts can also help during installation. Picture the ferrule sliding onto the pipe, followed by the nut. Adjusting these components requires steady hands and an eye for detail. In the end, taking your time to understand each piece and its function will lead to a more effective plumbing setup. Mistakes can happen, but they often provide valuable lessons for future projects.

| Fitting Type | Material | Size Range (inches) | Working Pressure (psi) | Common Applications |

|---|---|---|---|---|

| Straight Compression Fitting | Brass | 1/4 to 1 inch | 1500 | Water supply lines, Gas lines |

| Elbow Compression Fitting | Copper | 1/2 to 3/4 inch | 1200 | Pipes connecting at angles |

| Reducing Compression Fitting | Stainless Steel | 3/8 to 1/2 inch | 1000 | Adapt different pipe sizes |

| Cap Compression Fitting | Plastic | 1/2 to 1 inch | 800 | Cap off unused pipe ends |

| Tee Compression Fitting | Brass | 3/4 inch | 1500 | Branching pipes |

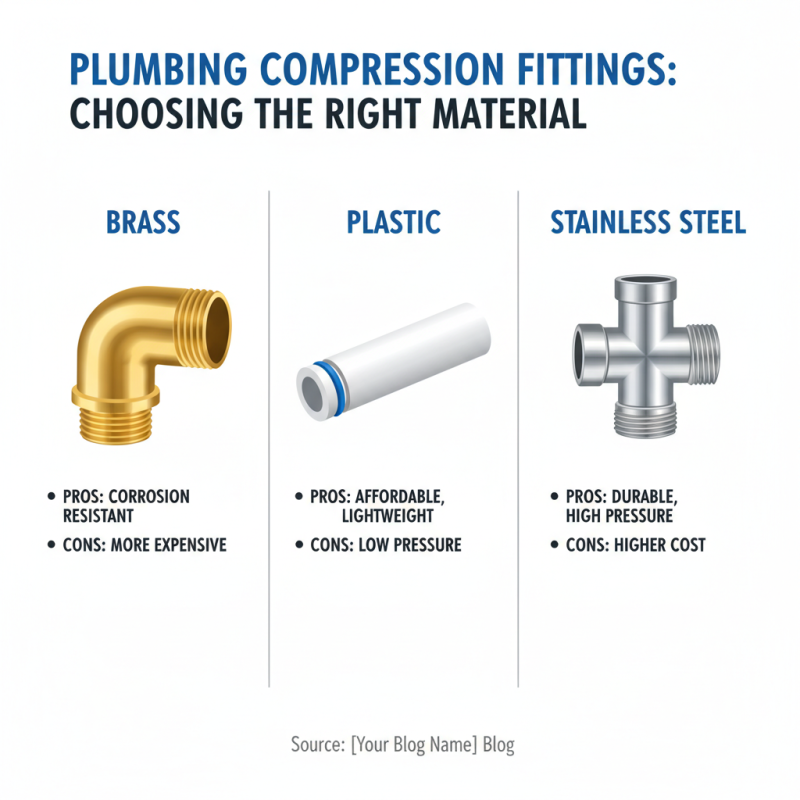

Compression fittings serve as crucial components in plumbing systems, connecting pipes securely. Understanding the various types available can enhance your plumbing projects. These fittings are usually made from materials like brass, copper, and plastic.

Brass compression fittings are often favored for their durability. They are resistant to corrosion, making them ideal for water supply lines. Studies show that brass fittings can last over 50 years with proper maintenance.

Plastic options, on the other hand, are lightweight and easier to work with. Yet, they may not withstand high-pressure situations as effectively.

Copper compression fittings are known for excellent thermal conductivity. However, they can be more expensive and may require special tools for installation. The market has seen an increase in mixed-material systems, combining these features. While some find this innovative, challenges remain in compatibility and long-term reliability. It's essential to consider the specific requirements of your plumbing needs before deciding.

When choosing compression fittings for plumbing, several factors play a crucial role. The material of the fittings is important. Most common options include brass, plastic, and stainless steel. Each material has its pros and cons. For example, brass fittings resist corrosion well but can be more expensive. Plastic fittings are lightweight and affordable but may not hold up under high pressure.

Another key factor is the size of the fitting. Ensure it matches your pipe diameter precisely. A fitting that is too loose can lead to leaks, while one that is too tight may damage the pipe. When measuring, use a caliper for accuracy. Take your time; a small error can cause big problems.

Tips: Check for compatibility with your existing plumbing. It’s critical to avoid mismatching materials, as this can lead to unexpected failures. Don't overlook the importance of the thread type as well. Consult a plumbing professional if uncertain. Remember, ensuring a proper fit can save you time and money in the long run.

When considering compression fittings for plumbing, it's essential to evaluate different brands and their features. A good fitting should ensure a leak-free connection. Many fittings are made from durable materials such as brass or stainless steel. These materials offer resistance against corrosion and enhance longevity.

Not all fittings fit every pipe perfectly. Some brands focus on specific pipe sizes and types. It's crucial to measure accurately before making a purchase. Designs vary significantly; some use unique compression techniques that simplify installations. However, not all claims of easy installation may hold true in reality. You might encounter situations where fittings seem incompatible, requiring additional adjustments or tools.

User reviews are a mixed bag. Some praise the reliability of certain brands, while others face frustrations with leaking or fittings weakening over time. It's wise to balance price with quality. Expensive doesn't always mean better. Take time to research and read feedback thoroughly. A thoughtful decision can save you from costly repairs later on.

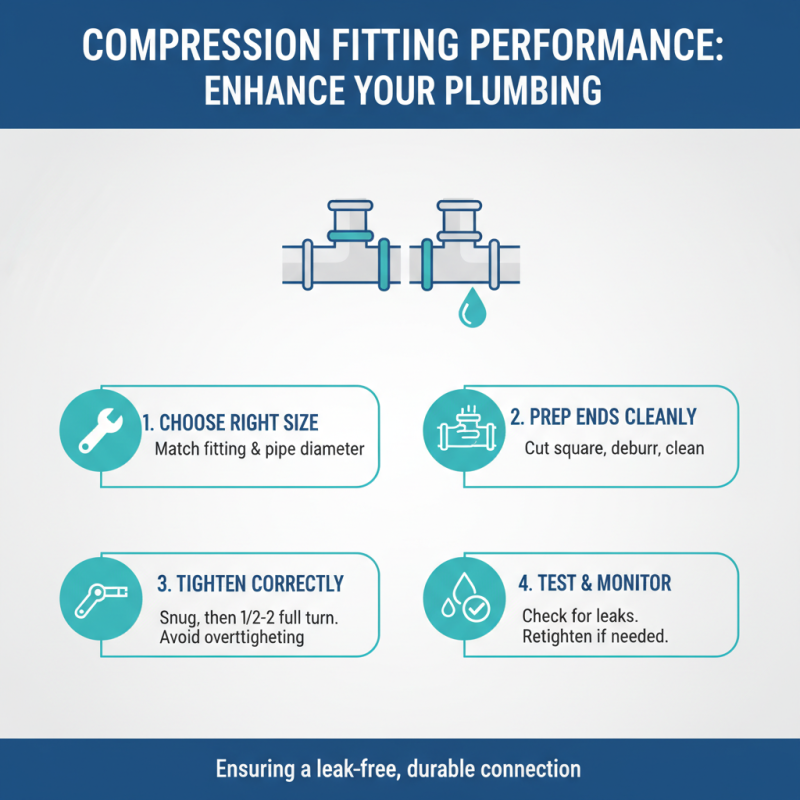

Compression fittings are essential for connecting pipes in plumbing systems. Proper installation ensures no leaks and longevity. Here are some tips to enhance your compression fittings' performance.

Start by ensuring the pipe ends are smooth. Any rough edges can lead to leaks. Use a deburring tool if necessary. Make sure to tighten the fitting by hand first, then use a wrench. Over-tightening can actually crack the fitting. A snug fit is all you need.

Remember to choose the right size for your pipes. Using a mismatched fitting can cause serious issues later. Don’t rush this step. Measure twice and cut once. If water starts to leak after installation, revisit your connections. A careful examination can save you from future headaches.

Always inspect the fittings regularly. Look for signs of wear or corrosion. Stainless steel options can provide better durability. It's okay if you find minor issues. Address them early to prevent larger problems. Proper attention to your compression fittings can lead to a well-functioning plumbing system.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.