In the ever-evolving landscape of industrial solutions, ball valves stand out as a critical component for efficient flow control. John Smith, a leading expert in the valve industry, emphasizes, “The right ball valve can significantly enhance system performance.” This statement underscores the importance of choosing suitable valves for operational efficiency.

Ball valves offer reliable sealing and quick shut-off capabilities. Their robust design allows for easy maintenance and longevity in various applications. However, not all ball valves are created equal. Companies often focus on cost over quality, leading to subpar performance. The challenge lies in identifying the best options that balance cost and durability.

When evaluating ball valves for your needs, consider factors like material and design. Some valves perform well under high pressure but may fail in corrosive environments. Investing time in understanding these variables is essential. As we look into the best ball valves for 2026, recognizing the shortcomings of current products can guide future improvements.

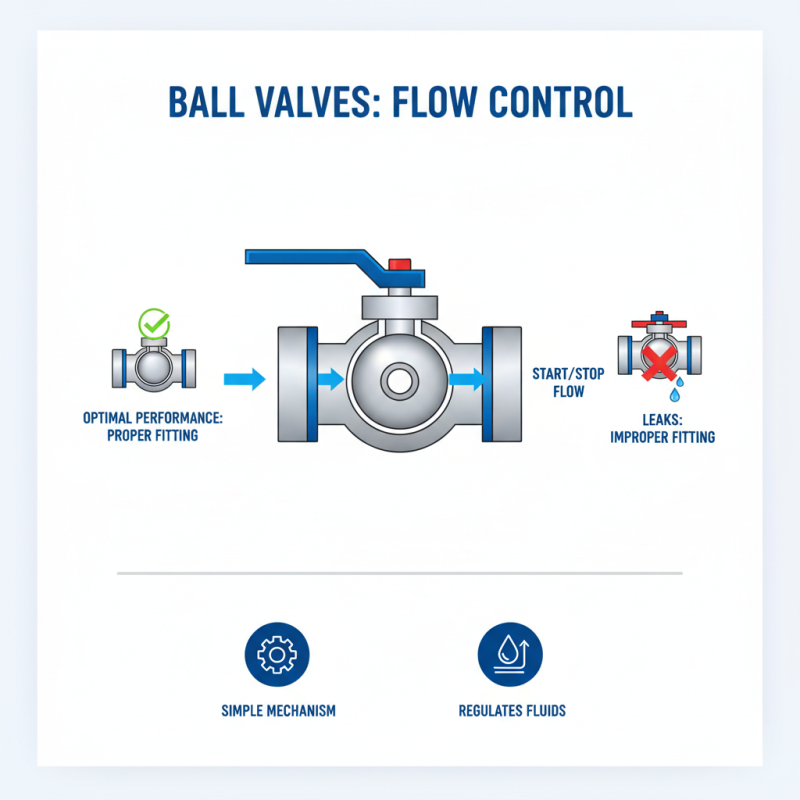

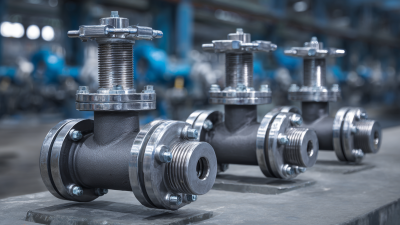

Ball valves play a crucial role in flow control systems. They allow for easy regulation of fluids through pipes. A ball valve consists of a spherical disc with a hole in the center. This design enables it to start or stop flow effectively. The simplicity of the mechanism is its strength. However, installation mistakes can lead to leaks. Proper fitting is vital for optimal performance.

Tips: When installing, ensure the valve is oriented correctly. This avoids pressure build-up and damage. A slight misalignment can create inefficiencies. Always check seals and connections. This prevents future maintenance issues.

The importance of ball valves extends beyond efficiency. They are used in various industries, including water treatment and manufacturing. Understanding their function helps in achieving desired outcomes. Users must note that not all valves are the same. Different applications require specific types. It’s essential to research the right valve for your needs. This may seem easy, but many overlook this step.

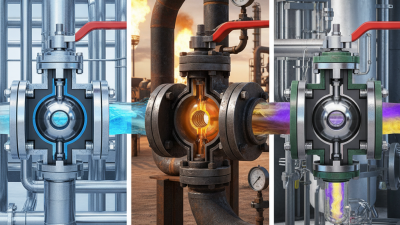

When selecting a ball valve, several key features demand attention. First, materials matter. The most common types are stainless steel, brass, and PVC. Each material offers unique benefits and drawbacks. For example, stainless steel resists corrosion but can be expensive. PVC is lightweight and economical but may not withstand extreme temperatures. According to a recent industry report, 45% of users ranked material selection as a top priority when sourcing ball valves.

Another crucial feature is the size and type of the valve connection. Options include threaded, flanged, or welded connections. Each type plays a critical role in ensuring optimal flow and leak prevention. Research shows that improper connection types can lead to a 30% increase in maintenance costs over time. Additionally, pay attention to the valve’s pressure rating. It should match or exceed the system's requirements. Accurate pressure ratings can prevent failures that lead to costly downtimes.

Actuation method is also important. Ball valves can be manually operated or automated. Automated options can improve efficiency but may require a higher upfront investment. An analysis by a leading engineering firm found that automated valves reduced operational time by 20%. This balance between initial costs and long-term savings should be carefully considered when making a selection.

| Ball Valve Type | Material | Size (inches) | Pressure Rating (PSI) | Temperature Range (°F) | Connection Type |

|---|---|---|---|---|---|

| Standard Ball Valve | PVC | 1 | 150 | 32 to 140 | Socket Weld |

| Trunnion Mounted Ball Valve | Carbon Steel | 2 | 600 | -20 to 300 | Flanged |

| Floating Ball Valve | Stainless Steel | 1.5 | 200 | -40 to 260 | Threaded |

| Electric Ball Valve | Brass | 1 | 300 | -10 to 200 | Flanged |

| V-Port Ball Valve | Ductile Iron | 2.5 | 150 | 0 to 350 | Socket Weld |

When choosing ball valves for efficient flow control, various brands stand out in 2026. Each brand offers unique features that cater to different needs. Some focus on durability. Others emphasize ease of installation. Quality materials contribute to a long lifespan, reducing the likelihood of leaks.

A few brands enhance their products with innovative designs. This can include ergonomic handles or smart technology. These innovations aim to simplify operation and maintenance. Yet, not every feature suits all environments. It’s crucial to assess the specific requirements of your application. Users must ask: "Is this the right fit?" Some features may add unnecessary complexity, leading to potential issues.

Another noteworthy aspect is cost. Investing in high-quality ball valves can lead to savings on repairs. Conversely, opting for a cheaper option might seem attractive initially. However, it can result in frequent replacements or inefficiency. Make informed choices based on real needs rather than trends. Reflecting on your requirements ensures you find the best ball valve for your flow control solutions.

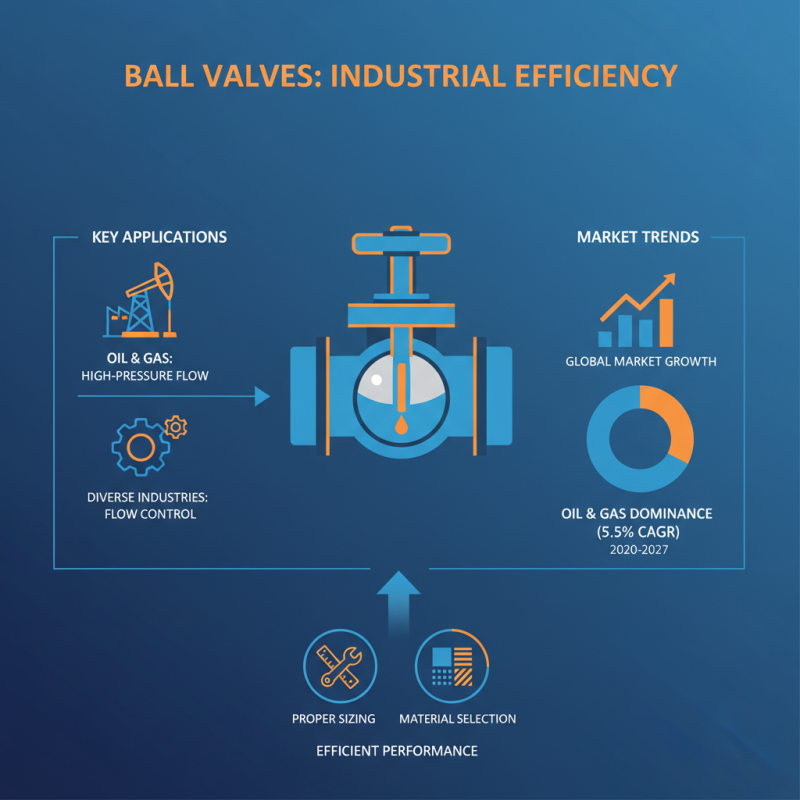

Ball valves have found extensive applications in various industries due to their efficiency and reliability. In the oil and gas sector, these valves are crucial for managing flow under high-pressure conditions. According to a report by Grand View Research, the oil and gas industry is expected to dominate the market, with a projected CAGR of 5.5% from 2020 to 2027. However, efficient performance relies on selecting the right valve size and materials.

In the water treatment industry, ball valves play an essential role in controlling the flow of water and chemicals. Their tight seals prevent leaks during operation. A recent study by MarketsandMarkets indicated that the global water treatment market is anticipated to reach $800 billion by 2025. This growth highlights the importance of reliable flow control solutions like ball valves. Yet, many companies still overlook the importance of regular maintenance. Neglect can lead to performance degradation over time.

Furthermore, the HVAC industry utilizes ball valves for regulating heating and cooling systems. This sector requires precision to maintain energy efficiency. According to Research And Markets, the HVAC market is projected to grow significantly, driven by rising energy costs. However, not all installations consider the impact of improper valve selection. This could result in energy waste and increased operational costs. Organizations need to address these concerns for optimal performance.

Proper maintenance is crucial for optimizing ball valve performance. Regular inspections can prevent unexpected failures. Check for any signs of wear or corrosion. These issues can lead to inefficient flow control. Cleaning the valve surfaces helps in maintaining smooth operation. Accumulated debris can hinder performance.

Lubrication is often overlooked. A small amount can significantly enhance functionality. However, it's important not to over-lubricate. Excess grease can cause buildup and create new issues. Tightening loose connections ensures a good seal. It is a simple yet effective way to enhance performance.

Long periods of inactivity can also negatively impact valves. Regular exercise of the valve helps keep seals pliable. This can extend the lifespan of your equipment. If you notice unusual noises, investigate promptly. Addressing minor issues early can save costly repairs later. Performance optimization requires ongoing attention, not just occasional adjustments.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.