In the rapidly evolving landscape of fluid valves, it's essential to stay ahead of innovations and trends. Industry expert Dr. Emily Chen stated, “Fluid valves are at the core of efficient system design.” This highlights the pivotal role these components play in various applications, from manufacturing to energy sectors.

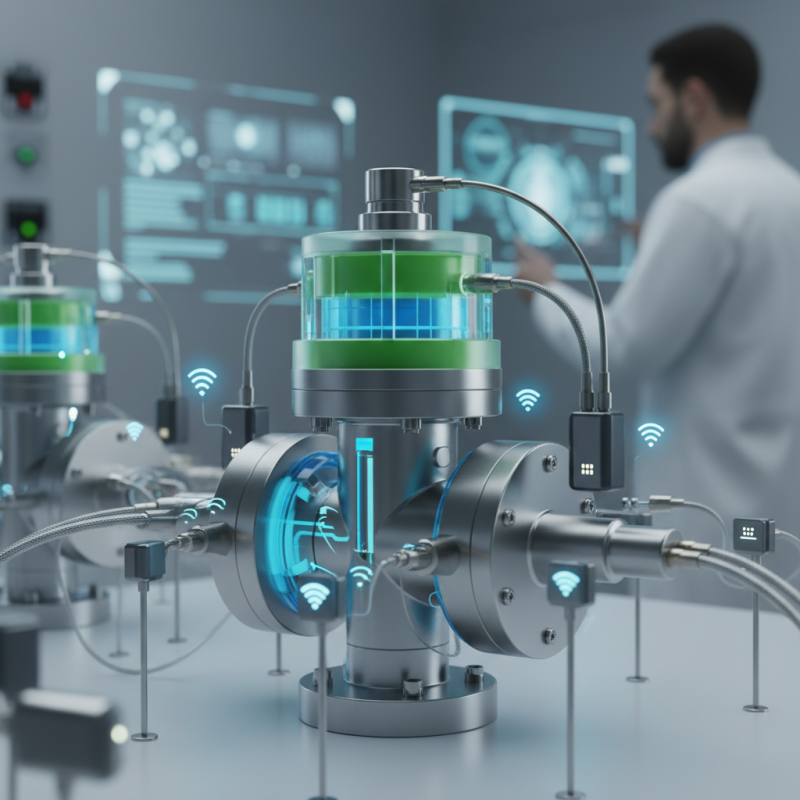

Emerging technologies are reshaping the fluid valves sector. Companies are investing in smart solutions that enhance performance and reliability. For instance, integrating IoT capabilities can lead to real-time monitoring and predictive maintenance. These advancements aim to reduce downtime and improve efficiency. However, not all innovations are perfect. Some technologies may face integration challenges, leading to unexpected costs.

Moreover, the demand for eco-friendly solutions is rising. The industry is exploring materials and designs that minimize environmental impact. Yet, achieving sustainability while maintaining performance is complex. Companies must carefully assess trade-offs. As we approach 2026, the future of fluid valves remains uncertain but exciting. The quest for innovation continues.

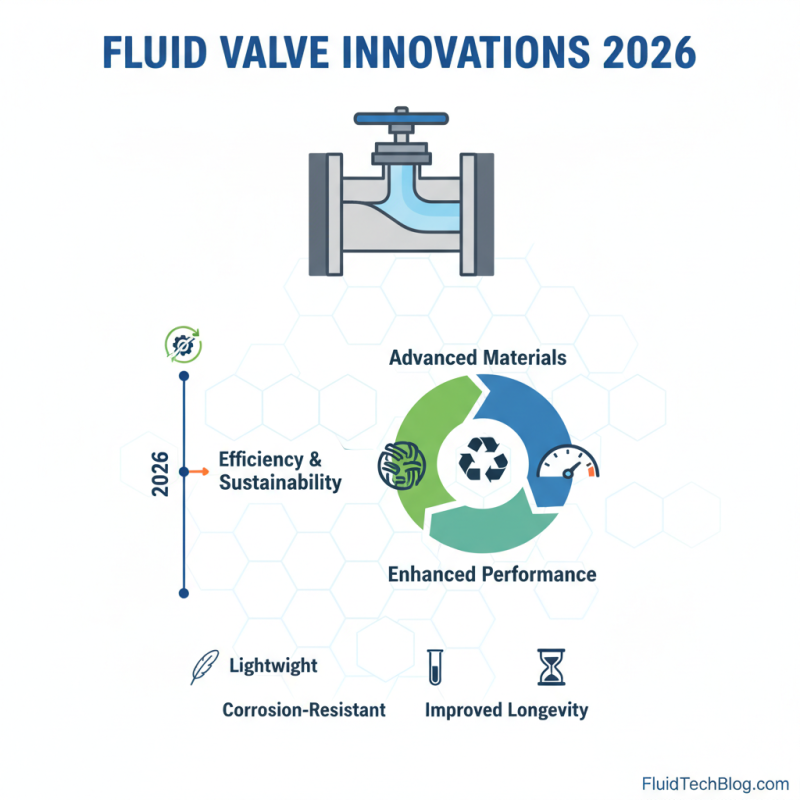

Fluid valves play a critical role in many industries. In 2026, innovations in design will focus on efficiency and sustainability. Advanced materials, such as composite plastics, will enhance performance. These materials are lightweight and resistant to corrosion, improving longevity.

Smart technology will revolutionize fluid valve design. Sensors will enable real-time monitoring of flow rates and pressures. This data will help operators make informed decisions. Yet, integration challenges may arise. Not all facilities are ready for smart applications, which could slow progress.

Another trend is the push towards modular designs. These allow for easier maintenance and customization. However, standardization remains a hurdle. Different industries have unique needs, making universal designs difficult. Continuous feedback from users will be essential for improvement. As we look ahead, the balance between innovation and practicality will be crucial for the industry’s growth.

Sustainability has become a core focus for the fluid valve industry. Companies are increasingly prioritizing eco-friendly practices. This shift not only helps the planet but also enhances their brand image. Manufacturing processes are evolving. Innovations include using sustainable materials and energy-efficient technologies. These changes aim to reduce waste and lower carbon footprints.

However, the transition is not without challenges. Some manufacturers struggle to find reliable sustainable materials. Additionally, the cost of implementing new technology can be high. This sometimes leads to hesitation in adopting eco-friendly solutions. There's a perception that going green may compromise performance. Industry leaders must address these concerns to drive broader acceptance.

Modular designs are emerging as a trend. They offer flexibility and can be updated without complete overhauls. Additionally, awareness about lifecycle analysis is growing. This understanding allows for better evaluation of products' environmental impact. Yet, not all companies are on board with these practices. There is still work to do in educating the entire industry about sustainability's long-term benefits.

This chart illustrates the impact of various innovations and trends shaping the fluid valve industry in 2026, with a focus on sustainability and efficiency. Each innovation is rated on a scale of 1 to 10 based on its expected impact on the industry.

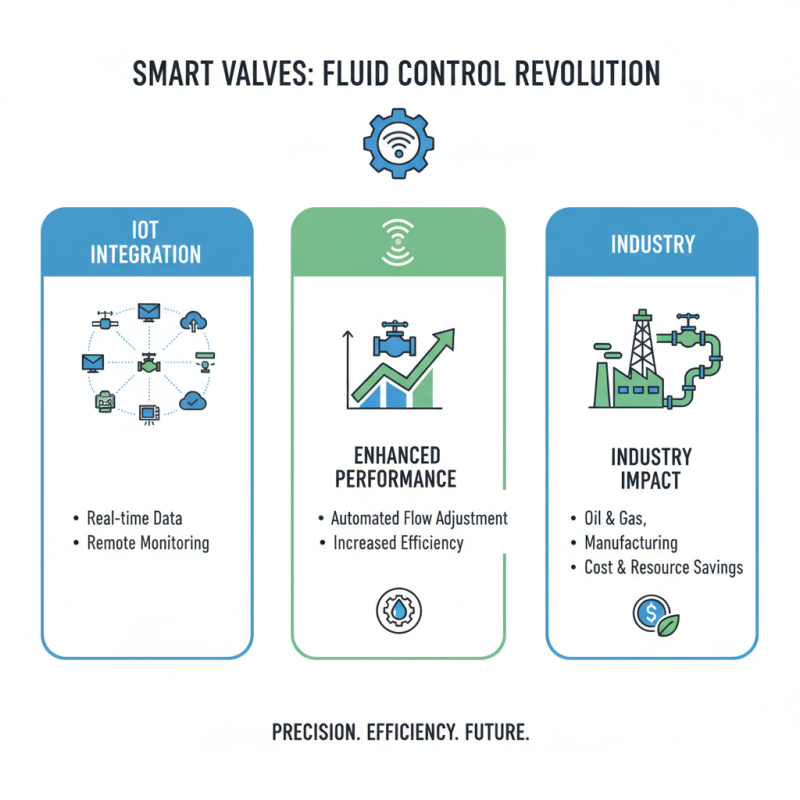

The rise of smart valves is transforming how industries manage fluid control. These devices integrate with the Internet of Things (IoT) to enhance performance and efficiency. Imagine a system that automatically adjusts flow rates based on real-time data. This flexibility is crucial for industries like oil and gas, where precision can save money and resources.

However, the integration of IoT with fluid valves presents challenges. Not all systems are compatible, leading to potential integration issues. Data security is also a concern. Smart valves generate valuable data, which must be safeguarded. Organizations must consider how to protect their information while reaping the benefits of connectivity.

In modern applications, predictive maintenance is a game changer. Sensors in smart valves can identify wear and tear. This insight allows for timely maintenance, reducing downtime. But not all users understand these systems fully. Training and education are vital. Without proper knowledge, the investment in smart valves may not yield expected benefits. Embracing these innovations requires a willingness to adapt and learn.

Regulatory changes significantly influence fluid valve innovations. As industries evolve, compliance becomes crucial. New regulations may require valves to meet stricter safety and environmental standards. Manufacturers need to adapt quickly. This may lead to innovative materials and designs to enhance efficiency.

Tips: Stay updated on regulatory requirements. This can prevent costly redesigns later. Communication with regulatory bodies can offer insight.

Technological advancements also play a role. Smart technology is becoming more common. Sensors in valves can monitor performance in real-time. This integration helps in maintaining compliance. However, adapting to new tech is not always seamless. Some companies may struggle with training staff or integrating systems.

Tips: Invest in staff training. A skilled workforce will better understand new technologies.

The path forward is filled with challenges. Balancing innovation with compliance requires careful planning. Companies must continuously evaluate their processes. Understanding both regulations and emerging technologies is essential for success. However, keeping pace can be daunting for smaller firms.

The fluid valves industry is poised for significant changes by 2026. Consumer demands are shifting towards smarter solutions. Automation in fluid management systems is crucial. Emerging technologies will dictate trends. The focus will be on energy efficiency and sustainability.

**Tip:** Consider user feedback seriously. It shapes product development.

In 2026, expect more integration with IoT devices. Remote monitoring will be commonplace. Consumers will want real-time data. This trend can help companies adapt faster. Yet, businesses must also address challenges. Not every innovation will meet all market needs.

**Tip:** Stay flexible with product designs. Adapt to unforeseen consumer needs.

Ethical manufacturing will also become a priority. Transparency in sourcing materials is increasingly important. Companies might face scrutiny for environmental practices. They must invest in sustainable solutions. Meeting these demands will ensure long-term success.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.