PVC check valves play a crucial role in fluid control systems. They ensure unidirectional flow, preventing backflow and enhancing system efficiency. Choosing the right PVC check valve can make a significant difference in long-term durability and performance.

In 2026, the market offers various options. Each valve comes with unique features tailored for specific applications. Some models excel in high-pressure environments. Others are designed for chemical resistance. Evaluating these aspects is essential for optimal usage.

However, many users overlook important factors. They often prioritize price over quality. This can lead to costly repairs and replacements. It's vital to assess both performance and reliability. A well-chosen PVC check valve can save time and money in the long run.

PVC check valves are essential components in various plumbing and industrial applications. They allow for the one-way flow of liquids and gases, preventing backflow. This is crucial in systems involving pumps and drainage. Their design ensures that fluid only moves in the desired direction. A tightly sealed mechanism prevents reverse flow, enhancing system efficiency.

These valves are frequently employed in agricultural irrigation systems, water treatment facilities, and chemical processing plants. Their lightweight nature makes installation easier. Yet, some may question their long-term durability under high-pressure conditions. Proper maintenance is necessary to avoid potential leaks and failures.

The material—PVC—provides resistance to corrosion and chemicals. However, exposure to extreme temperatures may compromise their integrity. Users must consider both the operational environment and the specific demands of their applications. These factors can influence the performance of PVC check valves significantly. Quality control during manufacturing can also vary. Making an informed choice means prioritizing reliability and performance.

When choosing PVC check valves, several key features deserve attention. Durability is paramount. These valves should withstand pressure and temperature variations. Look for options crafted from high-quality PVC materials. A study from the Fluid Control Association notes that valves with UV resistance can last up to 30% longer in outdoor settings.

Flow rate is another critical factor. The valve's design affects how fluid passes through. An efficient check valve minimizes backflow without restricting flow. The American Society of Mechanical Engineers recommends checking valves that offer precise flow measurement to optimize system efficiency.

Tips: Always verify size compatibility with your piping system. A mismatch can lead to leaks and system failure. Regular maintenance is essential. Inspect seals and joints to ensure long-term reliability. Budget should guide your choices. Investing in quality can lead to savings by reducing replacements and maintenance costs.

When considering PVC check valves in 2026, the focus must be on reliability and durability. Top manufacturers have enhanced their designs, meeting both industrial and residential needs. These valves, made from high-quality materials, resist corrosion and provide long-lasting performance.

A critical aspect of choosing the right manufacturer is the production process. Companies are investing in advanced technology and quality control systems. This helps in creating products that not only perform well but also meet stringent standards. However, not all manufacturers achieve this level of quality. Some still rely on outdated processes, leading to inconsistencies.

Furthermore, customer service plays a vital role in selecting a manufacturer. Efficient communication and support can significantly affect overall satisfaction. It's worth noting that while there are many options available, not every manufacturer prioritizes customer feedback. This oversight can lead to missed opportunities for improvement. In the competitive market of PVC check valves, a thoughtful approach is essential for making informed choices.

When selecting PVC check valves, reliability and durability are key factors. Various models exist, each with unique attributes. The construction material plays a crucial role in their performance. For instance, some valves are crafted from higher-grade PVC, offering better resistance to chemicals. Others might rely on standard PVC, which can be less durable under harsh conditions.

Testing these valves under extreme temperatures or heavy flow conditions reveals their weaknesses. Some models may fail after only a few months of use. Others show signs of wear, leading to leaks. Observing these traits can provide insights into which valves last longer and perform reliably. User feedback often highlights durability issues that manufacturers may overlook.

Choosing the right model requires careful consideration. A thorough comparative analysis is essential. It’s worth reading reviews and user experiences. Learn from others’ mistakes. The goal is to find a balance between initial cost and long-term reliability. Remember, not all PVC check valves perform equally.

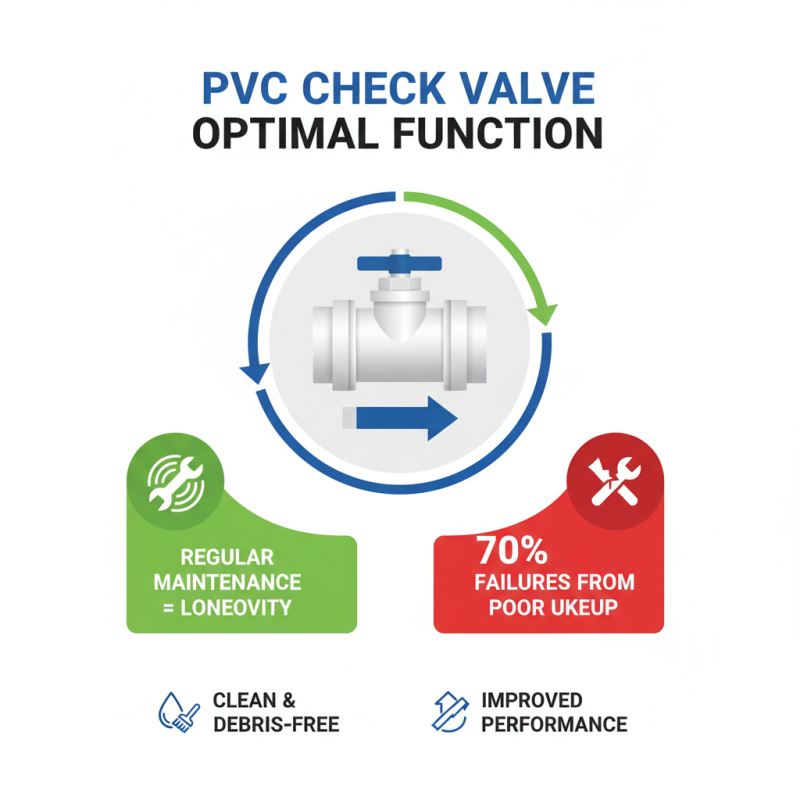

PVC check valves are vital in various applications, ensuring that fluid flow remains unidirectional. However, to keep them functioning optimally, regular maintenance is key. According to industry studies, roughly 70% of valve failures stem from inadequate upkeep. Ensuring these valves are clean and free from debris can drastically improve their performance and longevity.

Inspecting seals and gaskets regularly is crucial. Deterioration or wear in these components can lead to leaks. A report from the Fluid Control Institute noted that nearly 30% of leaks in PVC systems are attributed to faulty seals. Regular replacement can prevent costly downtime. In addition, it's advisable to monitor the surrounding environment. High temperatures and corrosive substances can negatively impact PVC check valves. Awareness of these factors can lead to timely interventions.

Some users overlook the importance of routine checks. This can create potential problems down the line. A simple visual inspection can often reveal early signs of wear. Even an overlooked crack might lead to significant issues. Therefore, establishing a maintenance schedule is essential. While it may seem tedious, it often saves time and resources in the long run. Investing in preventative measures can enhance the overall resilience of your PVC systems.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.