In recent years, the demand for efficient flow control solutions has surged. This shift has highlighted the importance of reliable components, especially cepex butterfly valves. These valves play a critical role in various industries, from water treatment to chemical processing. According to a report by MarketsandMarkets, the global butterfly valve market is projected to grow at a CAGR of 5.6% from 2021 to 2026.

Choosing the right cepex butterfly valves is paramount for ensuring optimal flow control. They offer advantages like lightweight design and low-pressure drop. However, not all valves meet the required standards. Some manufacturers may compromise on quality, leading to operational inefficiencies.

The ability to select the best options hinges on understanding specific application needs. Industry professionals must evaluate performance metrics and reliability. This requires ongoing research and possibly revisiting past selections. Investing in the right cepex butterfly valves is not just a choice; it's a necessity for achieving long-term operational success.

When it comes to flow management, butterfly valves offer distinct advantages. Understanding the different types can help you make informed choices. There are electronically actuated and manually operated types available. Each operates differently, yet both provide efficient control in various applications.

In a report by the Valve Manufacturers Association, the butterfly valve market is projected to grow by 6% annually through 2027. This growth reflects increasing demand for efficient fluid management in industries like wastewater treatment and chemical processing. For instance, soft-seated butterfly valves are often preferred for their tight sealing capabilities, reducing the risk of leakage.

However, challenges exist. Not all installations benefit equally from every valve type. Some users report issues with wear in high-pressure conditions. Identifying the right material for the seat and body is crucial. Operators should carefully assess their specific needs, as improper selections can lead to increased operational costs. Each application deserves attention to ensure you achieve optimal flow control.

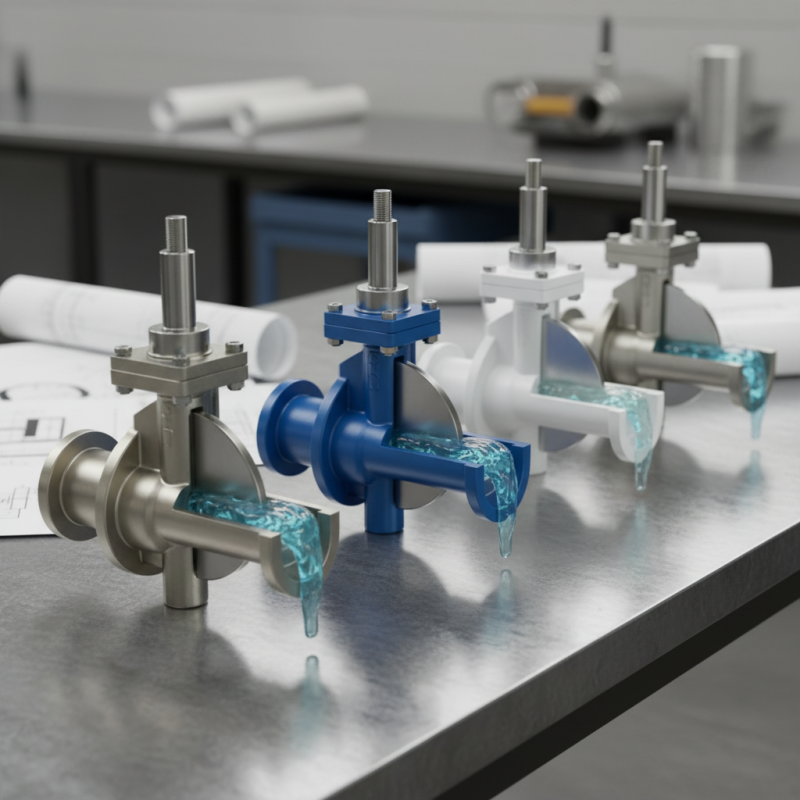

When considering butterfly valves for optimal flow control, several key features come into play. The design of the valve plays a crucial role. A lightweight construction allows for easier handling during installation. Look for durable materials that resist corrosion and wear. These factors greatly enhance the valve's lifespan and functionality.

Sealing performance is another essential feature. A reliable seal minimizes leakage, ensuring efficient operation. Seek valves with double-seated designs. They often provide better sealing capabilities. It's also wise to assess the actuator options available. The right actuator can significantly influence responsiveness and control.

**Tips:** Regular maintenance is crucial. Check seals and seating regularly. This helps identify issues before they become serious. Always review flow rates to ensure optimal performance. Sometimes, adjustments might be necessary to meet changing flow conditions. Remember, not every valve fits all applications perfectly. Choose wisely to avoid pitfalls.

This chart illustrates the key features of various butterfly valves that enhance flow control efficiency. The data represents the comparison of different valve sizes and their flow rates.

Cepex butterfly valves are versatile tools used in various industries. Their design allows for efficient flow control in both liquids and gases. Many sectors benefit from this, including water treatment, HVAC systems, and chemical processing. These valves can enhance operational efficiency while minimizing energy consumption.

In water treatment, Cepex butterfly valves help regulate flow rates. They ensure that water is distributed effectively. In HVAC applications, they control airflow in large systems. This helps maintain desired temperatures. Industries often face challenges like leaks or pressure drops. Choosing the right valve is crucial for performance.

Tips: Always consider the specific application before purchasing. Assess the media type, temperature, and pressure conditions. Regular maintenance is key to a long lifespan. Keep an eye on potential wear or damage over time.

In the chemical processing industry, butterfly valves offer reliable performance. They can handle corrosive fluids and high pressures. However, some users report difficulties in achieving a tight seal. This can lead to inefficiencies. It's important to choose the appropriate materials for your needs. Each industry has unique requirements, which should not be overlooked. Adjustments may be necessary for optimal results.

| Industry | Application | Valve Size (mm) | Temperature Range (°C) | Pressure Rating (bar) |

|---|---|---|---|---|

| Water Treatment | Flow Control in Filtration Systems | 100 | -10 to 60 | 10 |

| Oil & Gas | Pipeline Isolation | 150 | -20 to 80 | 16 |

| Food & Beverage | Brewery Process Control | 80 | 0 to 90 | 6 |

| Chemical Processing | Corrosion Resistant Flow Control | 200 | -30 to 150 | 10 |

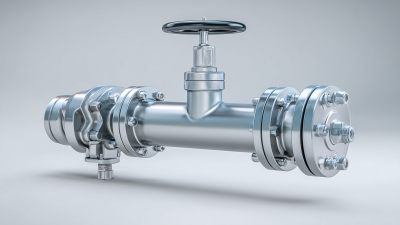

When evaluating flow control solutions, Cepex butterfly valves stand out against various other valve types. These valves feature a simple design that allows for easy operation and maintenance. Their lightweight structure contributes to better performance in many applications. However, there are situations where they may not excel.

Compared to gate or globe valves, butterfly valves can offer faster flow control, but they may struggle in high-pressure systems. Performance differences in turbulent conditions raise questions. While butterfly valves are effective in many scenarios, they may necessitate a backup plan in instances of extreme pressure. Selecting the right valve type depends heavily on the specific application.

Another consideration is the sealing mechanism. Cepex butterfly valves often rely on elastomeric seals that provide effective performance. However, wear and tear over time can lead to leaks. This is a common concern across many valve types. Regular maintenance and inspections are necessary to ensure they function optimally. Evaluating operational needs can be complex, but such scrutiny is essential to identifying potential weaknesses in your flow control system.

Maintaining butterfly valves is crucial for their performance and longevity. Regular inspections help identify wear and tear. Research shows that routine maintenance can extend valve lifespan by up to 30%. Check for leaks, as small issues can lead to significant inefficiencies. A small drip may seem minor, but it can waste a surprising amount of water.

Lubrication is essential for smooth operation. Use the right type of lubricant and apply it sparingly. Over-lubrication can attract dirt and create blockages. A study found that improper lubrication accounts for 25% of valve failures in industrial applications. In addition, replace seals when necessary to prevent leaks and ensure a tight shut-off.

Keep the valve environment clean. Dust and debris can affect performance. A clean valve can reduce maintenance costs by 15%. Pay attention to the operating conditions, such as pressure and temperature. Monitoring these conditions helps avoid premature wear. A little diligence goes a long way in extending the life of butterfly valves.

Cepex is the brand for the fluid handling market belonging to the Fluidra group. One of the leading european manufacturer of valves and fittings in thermoplastic materials.

Dedicated to the swimming pool, irrigation and industrial markets, we distribute our products worldwide with the Fluidra commercial network and presence in 46 countries with 136 sales branches.